Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

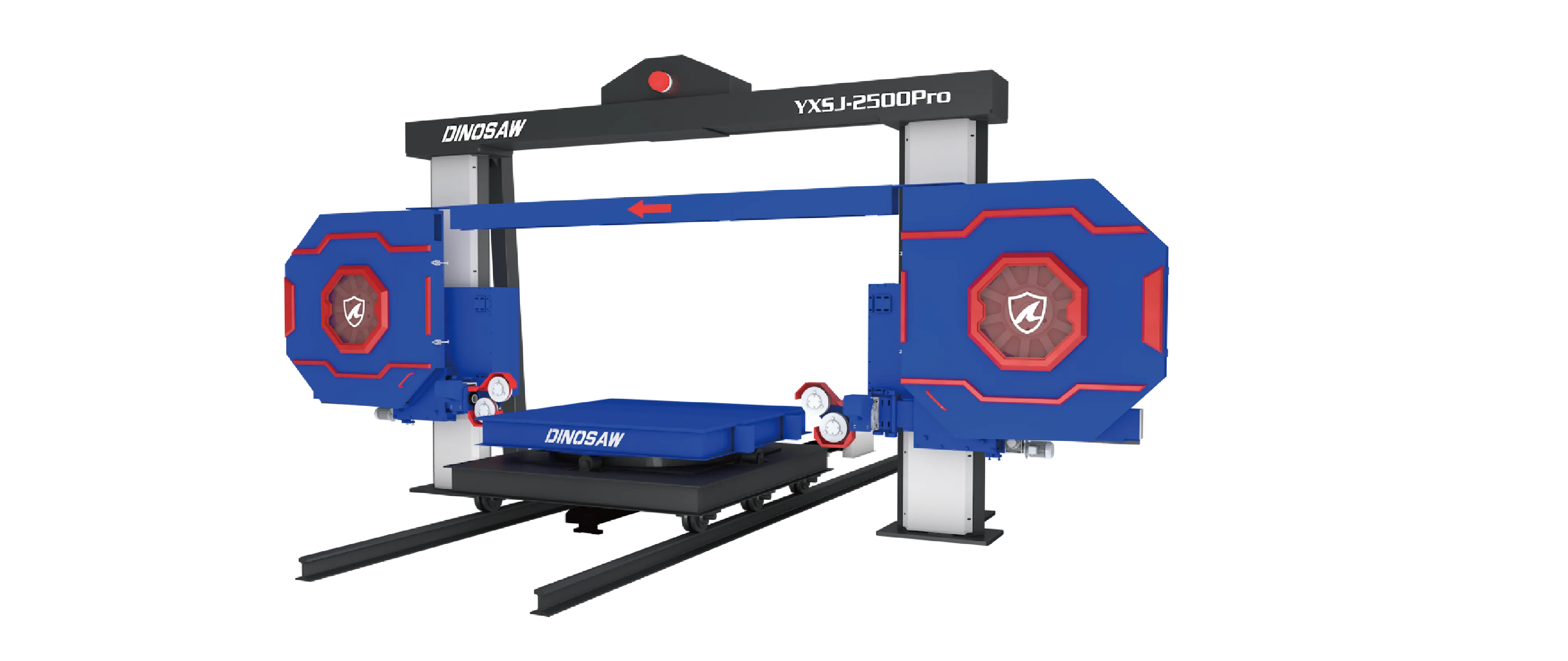

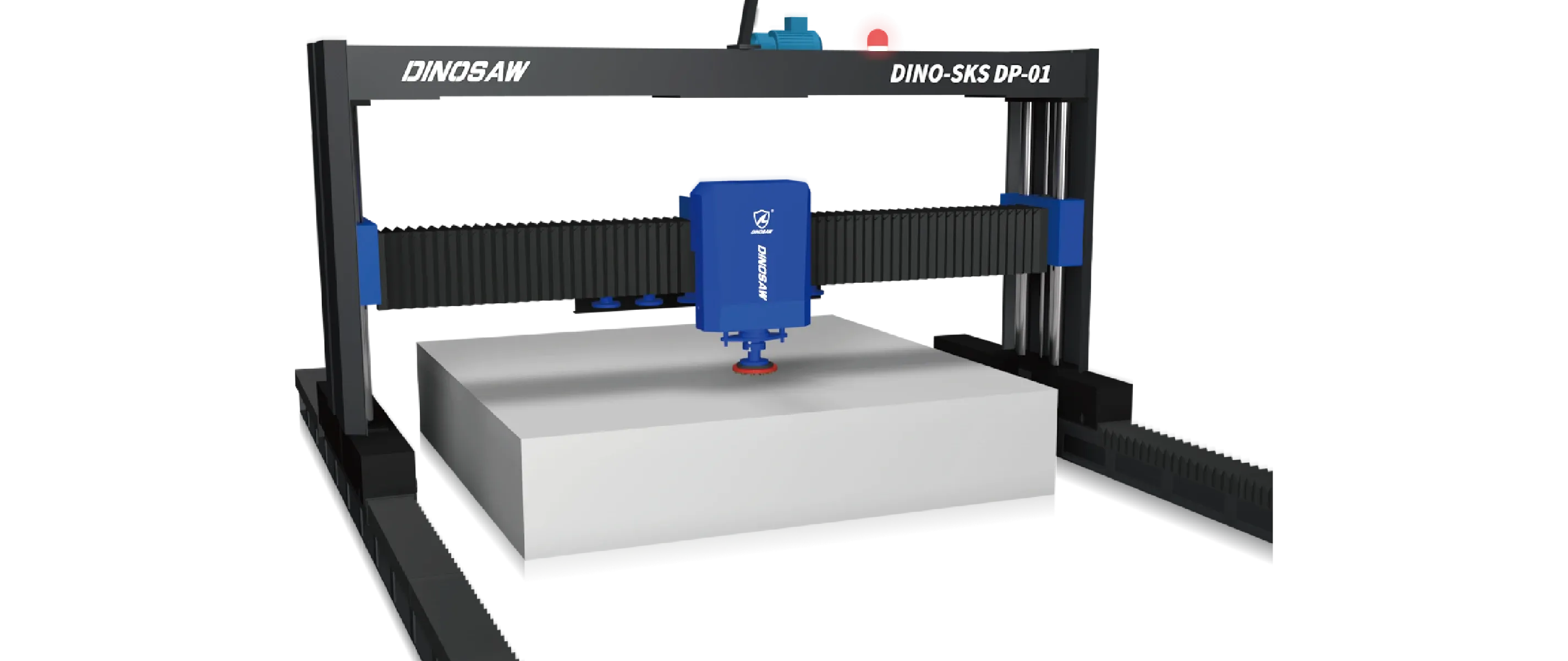

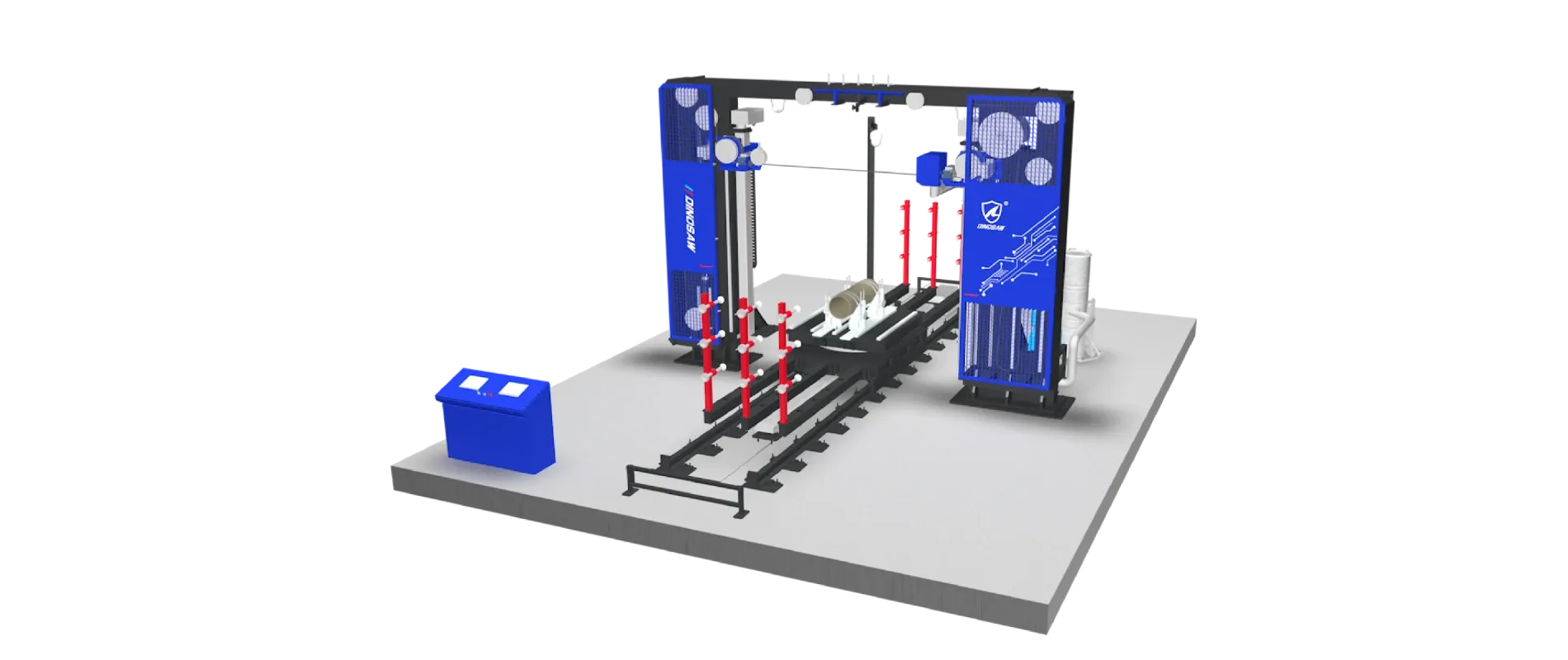

Need rock-solid precision for heavy-duty cutting? DINOSAW's gantry wire saw machines deliver the stability and accuracy your operation demands.

Ready to Transform Your Cutting Operations?

Heavy-duty cutting jobs got you frustrated with poor results? Let's be honest - when you're dealing with massive stone blocks or reinforced concrete structures, traditional cutting equipment often leaves you disappointed. Poor accuracy, excessive wire wear, and unstable results become costly headaches.

Whether you're processing quarried stone blocks or sectioning pre-cast concrete components in your facility, you need equipment that stays rock-steady under pressure. These aren't your typical on-site demolition jobs. We're talking about precision work that demands millimeter accuracy and smooth surface finishes every single time.

Contact DINOSAW's technical team today for a consultation and custom solution.

What makes gantry wire saws different from mobile units?

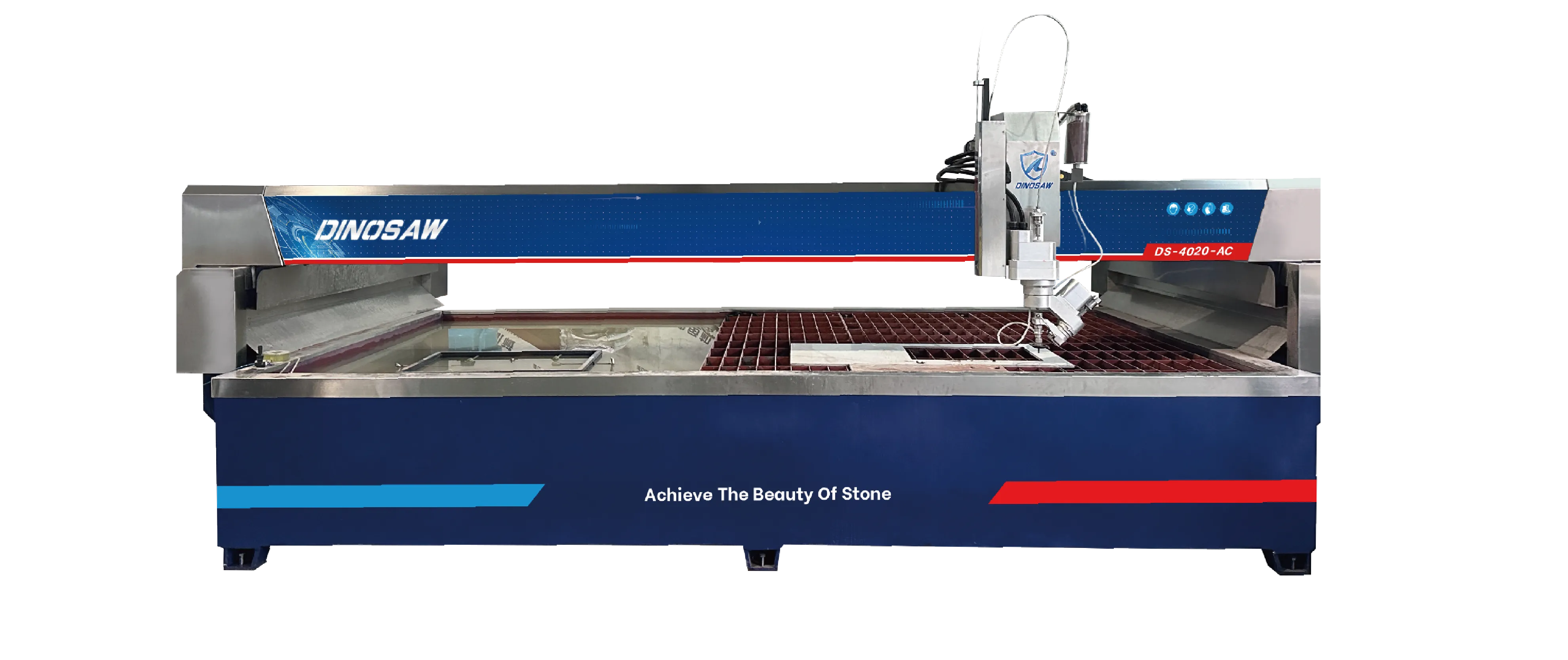

The DINOSAW gantry wire saw tackles these challenges head-on with its specialized design. Unlike mobile wire saws built for portability, this machine prioritizes absolute stability and precision above all else.

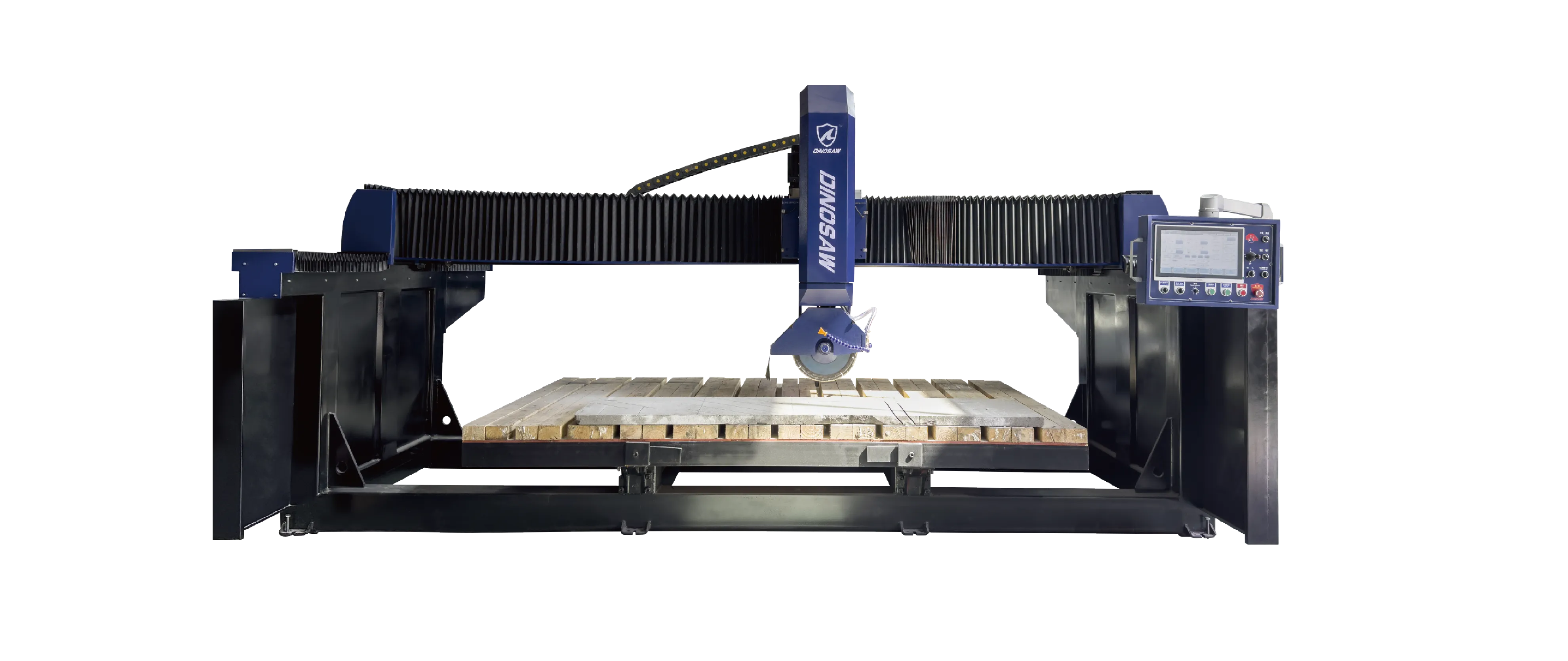

Here's the key difference: while mobile saws work great for on-site wall cutting and general demolition, gantry systems excel at controlled, high-precision cutting of heavy materials in factory environments. Think bridge segments, large-diameter pipes, and massive concrete columns that need perfect cuts every time.

How does the gantry structure eliminate cutting problems?

The secret lies in the dual-column "gate-like" frame design. This isn't just about looking sturdy - it's engineering that solves real problems.

Millimeter Precision

The rigid frame keeps your diamond wire perfectly vertical throughout the entire cutting stroke. No wobble, no drift - just straight, accurate cuts that eliminate costly secondary processing.

Faster Cutting

Stable operation means higher wire speeds without compromising quality. Get through your cutting jobs faster while maintaining that smooth finish you need.

Lower Operating Costs

Uniform wire stress means 20-30% longer diamond wire life. That's real money saved on consumables, plus less downtime for wire changes.

Which cutting jobs benefit most from gantry wire saws?

Gantry wire saws aren't general-purpose demolition tools. They're precision instruments designed for specific, high-value cutting applications.

Stone Processing Operations

In quarrying and stone fabrication, every cut matters financially. When you're processing expensive granite or marble blocks, waste isn't just inefficient - it's profit lost forever.

The gantry saw maximizes your material yield by delivering consistently accurate cuts. Whether you're sectioning massive quarried blocks or creating precise slabs, that millimeter-level accuracy translates directly to better material utilization and higher profits.

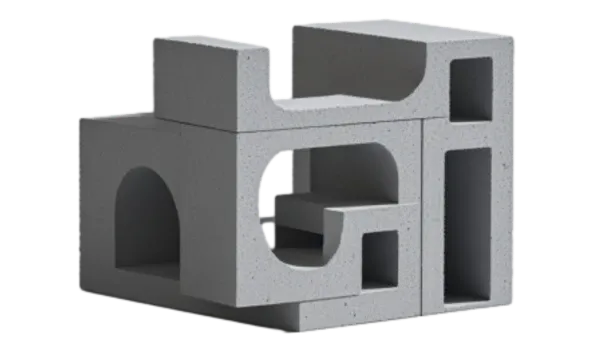

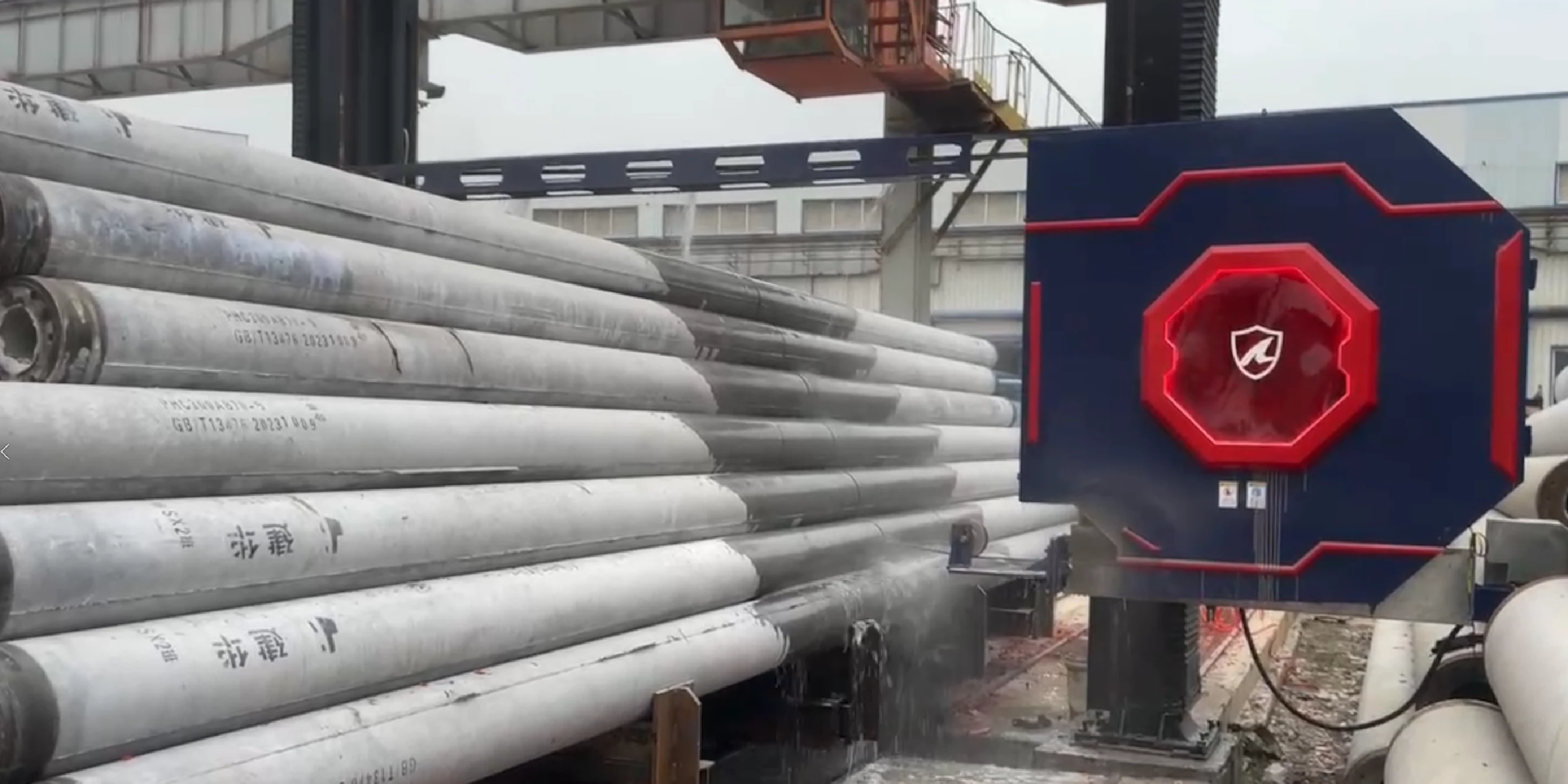

Heavy Industrial Structure Processing

This is where gantry saws really shine compared to mobile alternatives. When you need to process large, heavy concrete structures in a controlled environment, stability becomes everything.

Typical Applications Include:

- Bridge Segments: Precise sectioning of pre-cast concrete bridge components after transport to processing facilities

- Large-Diameter Pipes: Accurate cutting of high-strength concrete or composite pipes for construction projects

- Structural Columns and Beams: Processing oversized concrete elements in factory settings

- Specialized Projects: Nuclear decommissioning work requiring dust-free, vibrationfree cutting protocols

The key advantage? Moving complex cutting work from chaotic job sites to controlled factory environments. Better working conditions, enhanced safety protocols, and consistently superior results.

How do you choose the right gantry wire saw for your operation?

Selecting a gantry wire saw represents a significant investment. Smart buyers evaluate multiple factors beyond just cutting capacity.

Match Equipment Specs to Your Real Needs

Cutting Capacity Planning

Start with your largest, hardest materials. What's the maximum stone or concrete size you'll process? Factor in both current needs and anticipated growth. Don't forget material hardness - cutting granite requires different power and wire specifications than processing concrete.

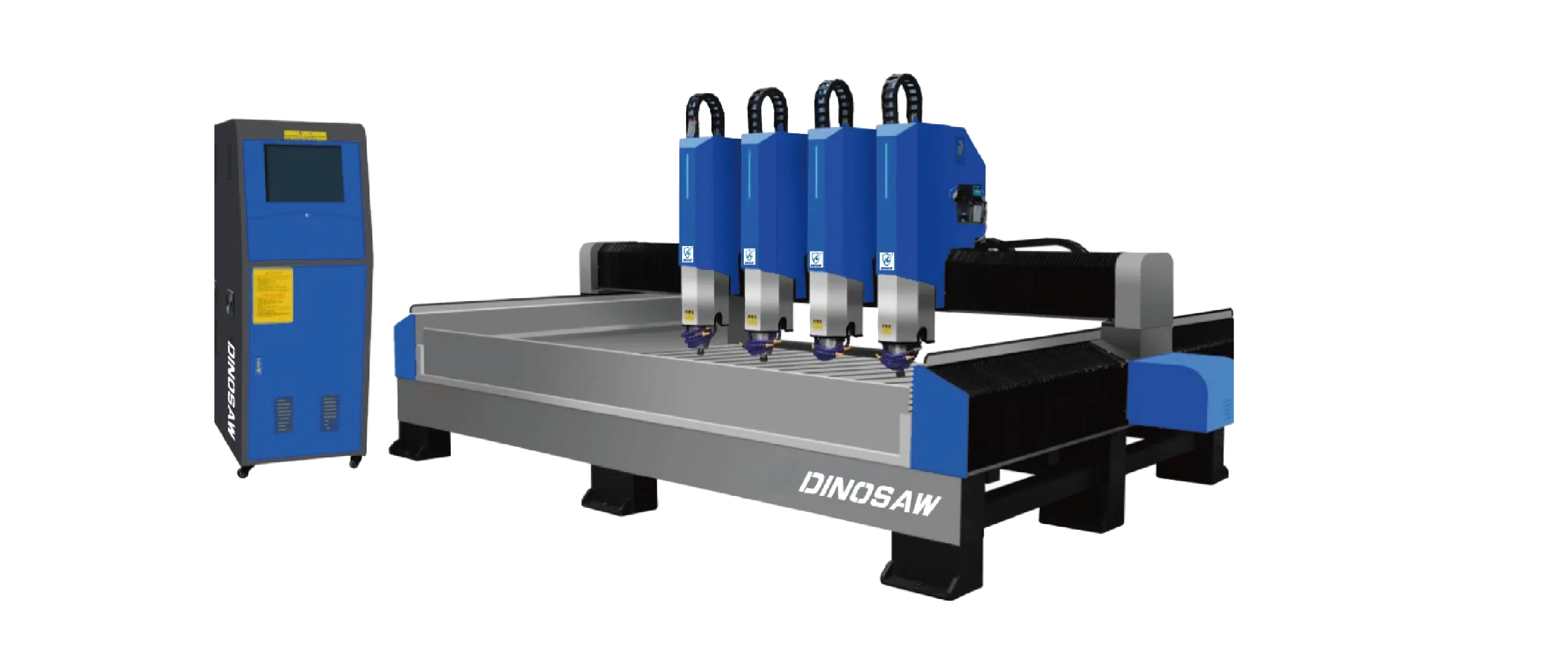

Control System Requirements

Modern PLC control systems aren't luxury features - they're operational necessities. Automated wire tension monitoring and speed control minimize operator error and maximize consistency.

Look for systems offering real-time parameter monitoring and data logging capabilities.

Why manufacturer expertise matters more than you think

Equipment reliability depends heavily on manufacturer support. When your gantry saw experiences downtime, every hour costs money.

DINOSAW provides comprehensive technical support, responsive service, and reliable parts supply. We understand that your equipment needs to run consistently to maintain profitability. Our team works with you to optimize cutting parameters for your specific materials and production requirements.

Common Questions About Gantry Wire Saw Machines

Gantry vs mobile wire saw - which should I choose for my project?

Choose based on your primary application. Mobile wire saws excel at on-site demolition where portability matters most. Gantry systems dominate when you need maximum precision for processing large materials in controlled environments - think stone fabrication facilities or pre-cast concrete processing plants.

What materials can gantry wire saws handle effectively?

DINOSAW gantry systems handle the full range of challenging materials. Natural stones like granite and marble are primary applications, but the exceptional stability also makes them ideal for reinforced concrete, steel-embedded structures, and composite materials. The key advantage is maintaining precision regardless of material hardness.

How does investing in a gantry saw improve my bottom line?

Three main cost benefits: reduced material waste through precise cutting, extended diamond wire life due to stable operation, and single-machine versatility replacing multiple specialized tools. Many customers see ROI within 18-24 months through these combined savings.

Are DINOSAW gantry saws difficult to operate?

Modern CNC control systems make operation surprisingly straightforward. Set your parameters, start the cut, and monitor progress. The automated systems handle most technical adjustments. We provide complete operator training and ongoing technical support to ensure your team maximizes the equipment's capabilities.

Why does manufacturer reputation matter when buying a gantry saw?

Equipment downtime kills productivity and profits. Reliable manufacturer support ensures quick problem resolution, readily available parts, and ongoing technical expertise. DINOSAW's commitment extends beyond the sale - we partner with customers for long-term operational success through comprehensive support and service programs.

Ready to upgrade your cutting capabilities?

DINOSAW gantry wire saw machines deliver the precision, stability, and efficiency your operation needs. Whether you're processing stone blocks or heavy concrete structures, our specialized equipment helps you achieve better results while reducing operating costs.

Contact our technical team to discuss your specific cutting requirements and discover how a DINOSAW gantry system can transform your operation's capabilities and profitability.

English

English