Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

An executive guide to ROI on stone lathes. Covers the decision checklist, precision repeatability, training & warranty, and our end-to-end support for your investment.

This executive guide is designed for business owners, production managers, and procurement leads tasked with making a strategic capital investment. Our goal is to align the right stone lathe configuration-size, structure, and control system-with your factory's specific constraints and value levers. A properly specified Stone lathe machine is not just a tool; it's a catalyst for higher yield, lower rework, and expanded market opportunities.

This document distills the most critical information from our in-depth series, providing a high-level, independently readable framework for your decision-making process. We will cover the product's core value, a quick-start checklist, key ROI drivers, and the end-to-end support you can expect from DINOSAW.

Start a pilot: define acceptance KPIs and ROI tracking with our team.

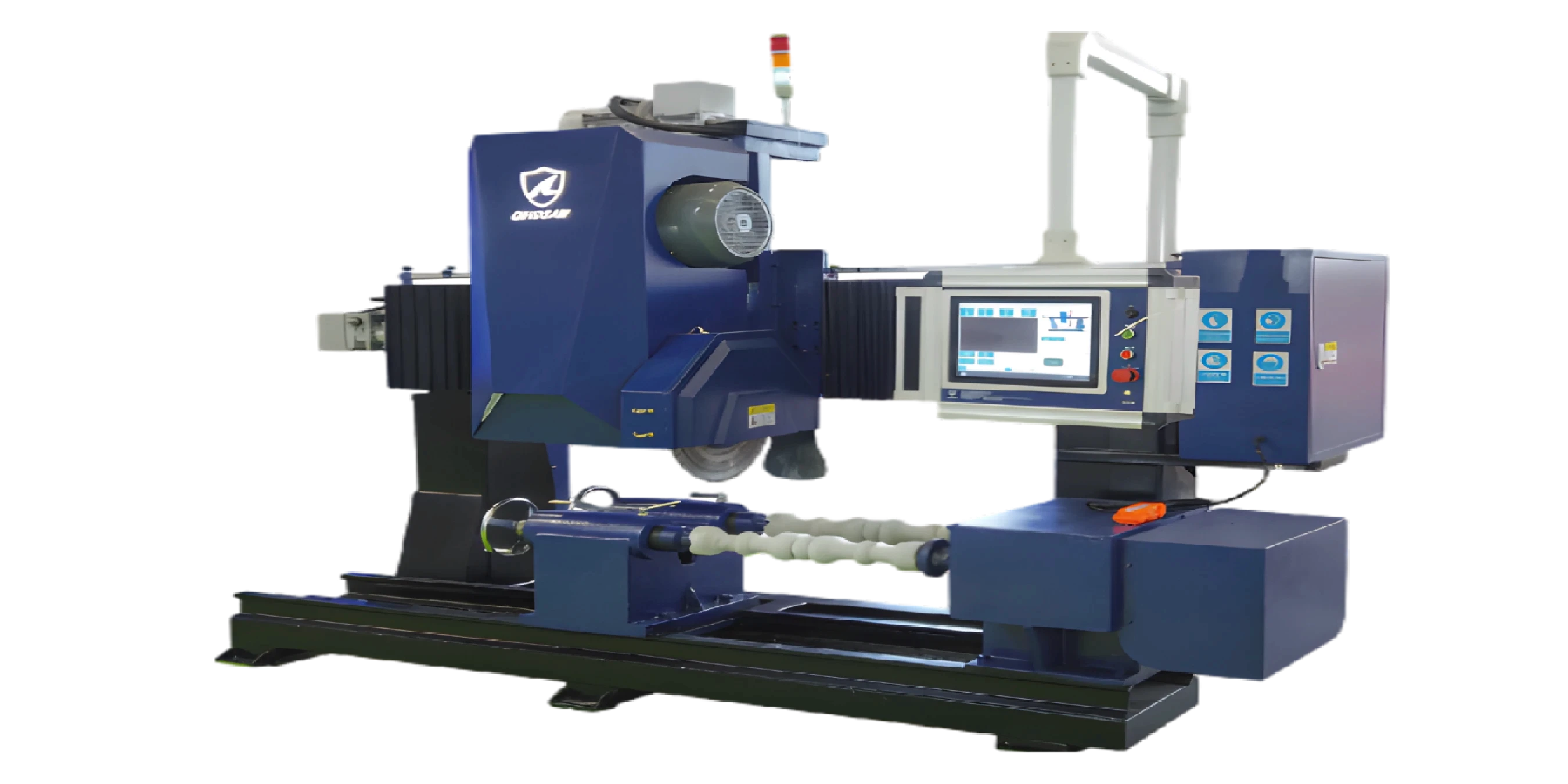

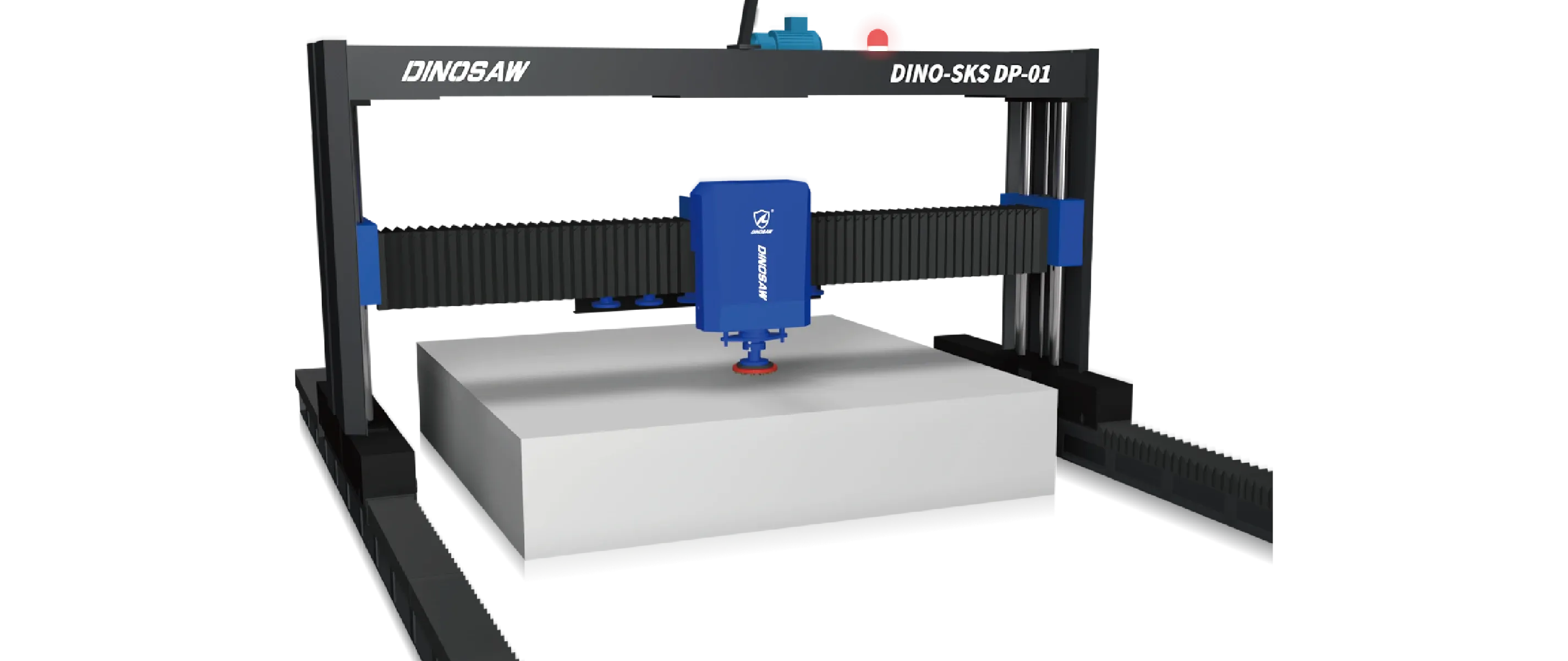

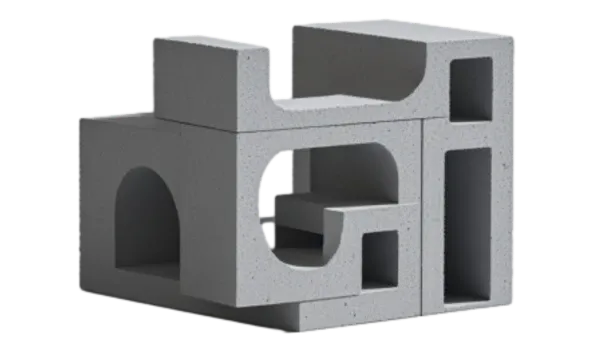

What A CNC Stone Lathe Is

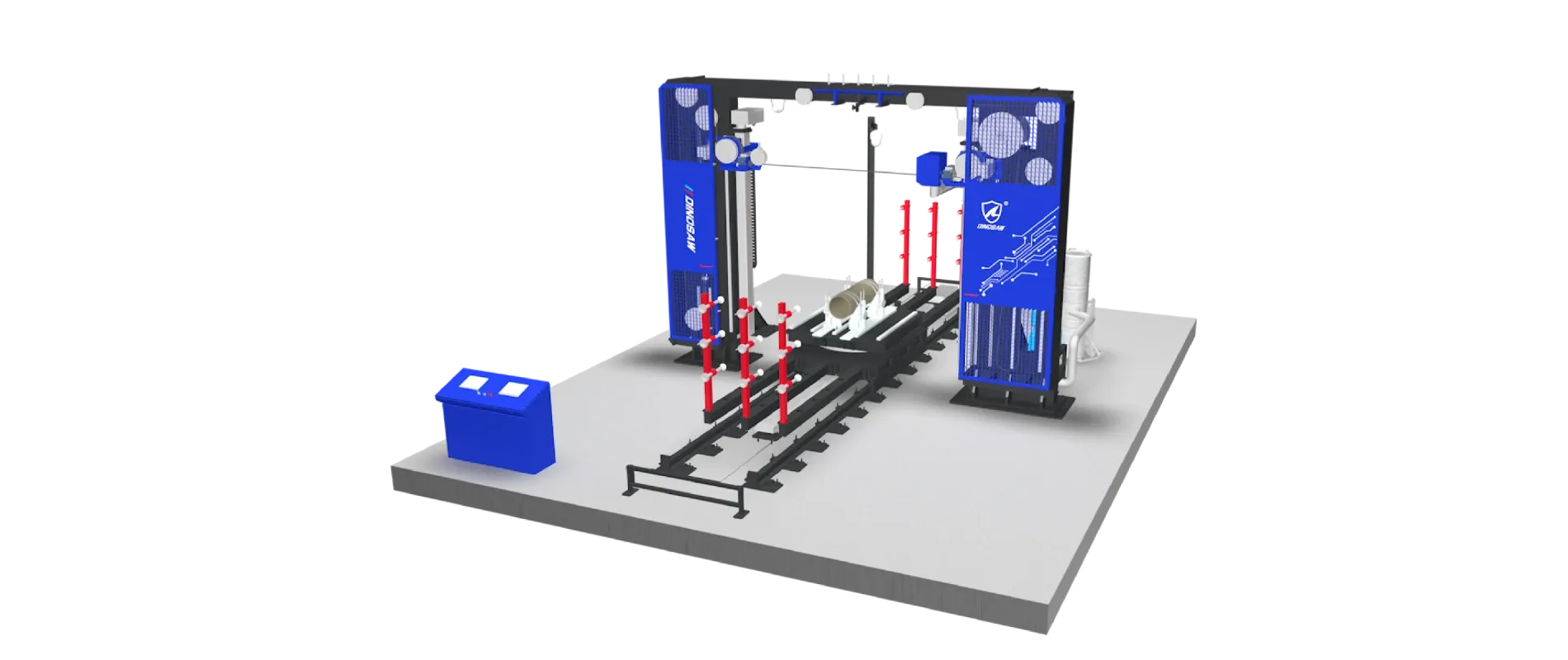

From an application perspective, the CNC stone lathe is a precision machine tool for producing cylindrical stone components, such as columns, balusters, and vases, making it essential for tasks like granite column turning. From a technical standpoint, its rigid frame and advanced control system, featuring bridge-type bidirectional cuts, minimize vibration and reduce material stress, ensuring superior finish and accuracy. This machine comes with a CNC system as standard for maximum flexibility, with a PLC option for high-volume, repetitive tasks.

Quick-Start Checklist for a Stone Turning Machine

- Environment: Requires a stable foundation, three-phase power, and a wet-cutting slurry management system.

- Safety: Mandatory PPE, interlocked guards, and compliance with local dust regulations (e.g., as per EU machinery safety guidelines).

- Parameters: Starting feed/speed/coolant settings are provided at commissioning and adjusted during trials.

- Size (Ø/L → Product): Match machine capacity (e.g., 1200mm length for balusters, 3000mm for columns) to your product mix.

- Structure (Vertical vs. Horizontal): Choose a vertical vs horizontal stone lathe based on part geometry-horizontal for long parts, vertical for large-diameter parts.

- Control (PLC vs. CNC): Choose a PLC vs CNC stone lathe based on work mix-PLC for repetitive tasks, CNC for custom profiles.

Decision Map for Baluster Profiling

- If producing high-volume, standard balusters, Then a horizontal PLC lathe offers the best TCO. (Risk: Inflexible for custom designs).

- If producing custom or complex baluster profiles, Then a horizontal CNC lathe is essential for programmability. (Risk: Higher initial cost and training).

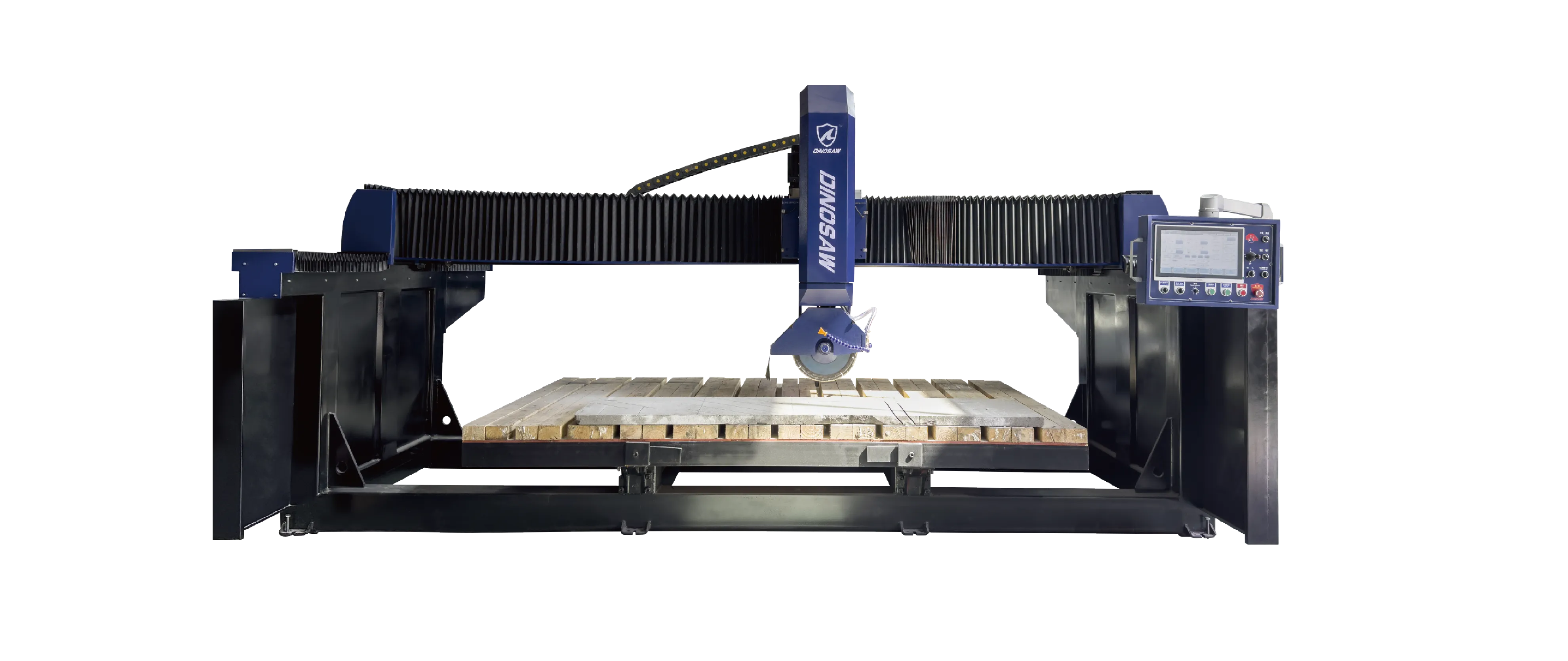

- If baluster production is only occasional, Then a bridge saw with a lathe attachment may suffice. (Risk: Lower precision and finish quality).

Summaries of Deeper Dives + Links

For more detailed information, please refer to our full series:

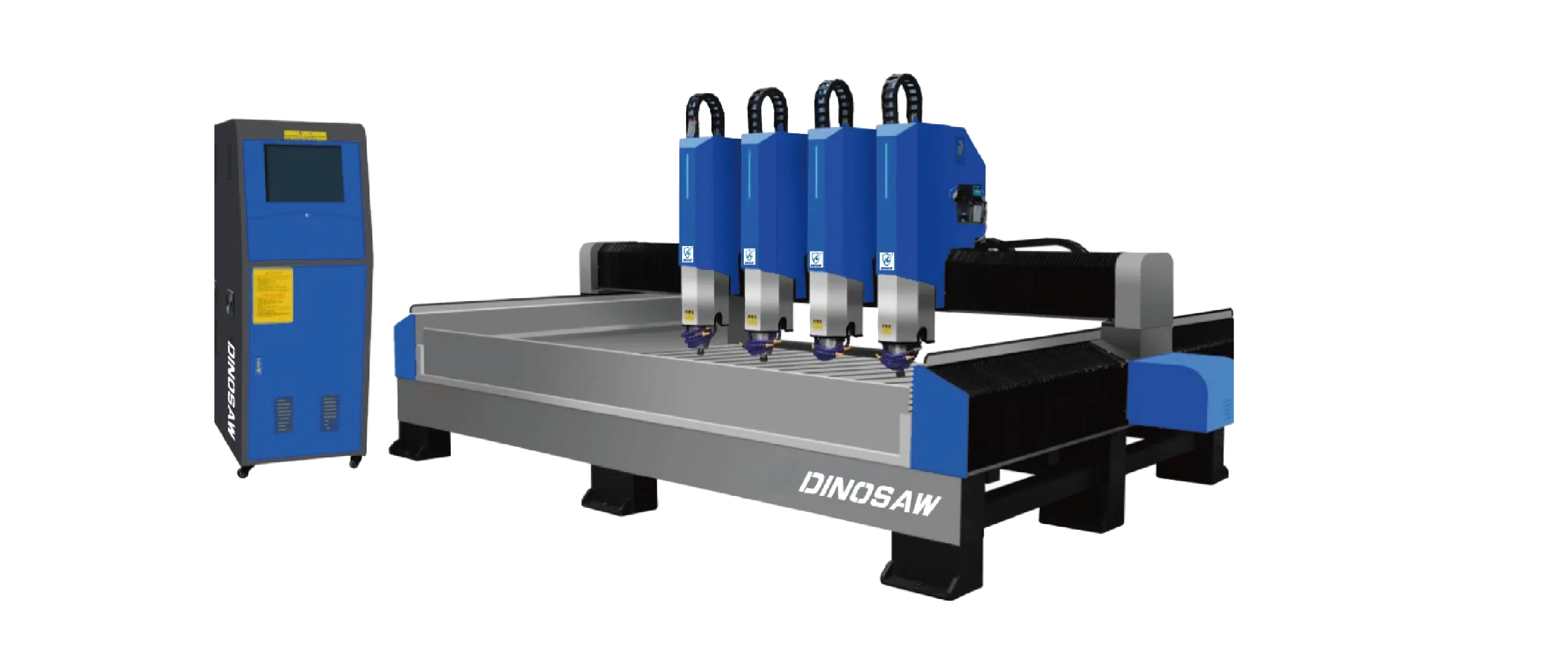

- CNC Stone Lathe Applications & Cases: Determine if the machine can process your specific parts by exploring its capabilities and material compatibility.

- CNC Stone Lathe Technical Guide: Deconstruct the machine’s architecture, from the spindle motor to control systems, to understand its operational parameters.

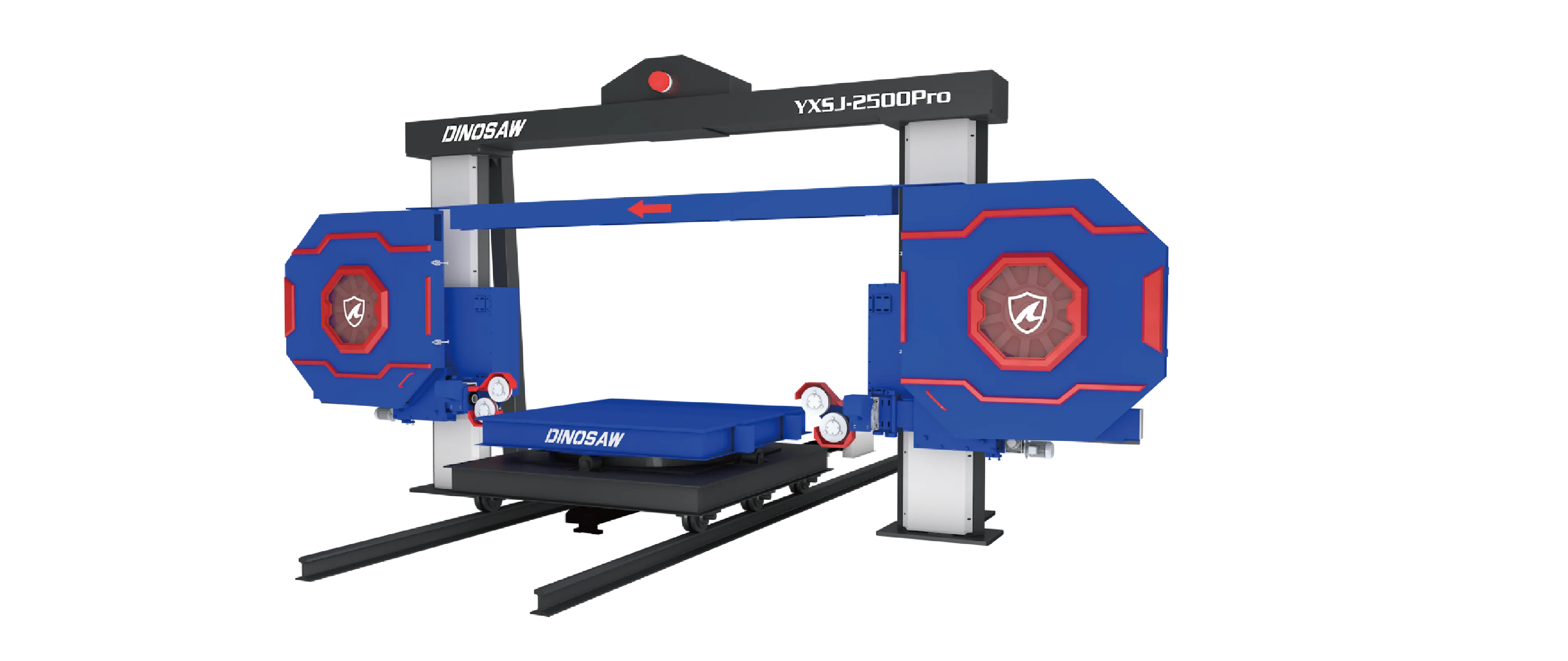

- CNC Stone Lathe Buyer's Comparison: Use our decision trees and TCO analysis to compare the lathe against alternative machines for your application.

- CNC Stone Lathe Maintenance & Troubleshooting: Implement our SOPs and maintenance schedules to maximize uptime and operational longevity.

From Pre-Sale to After-Sale: DINOSAW Support for Stone CNC Machinery

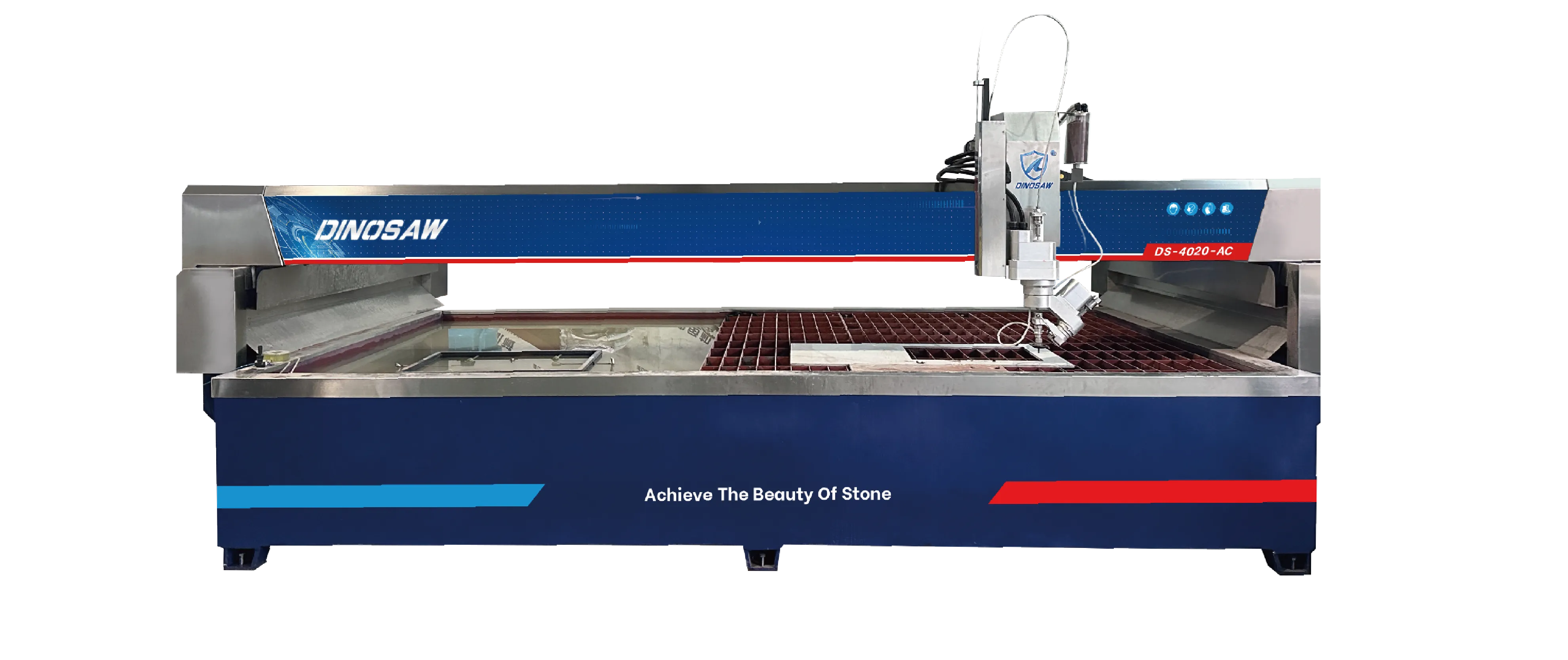

We provide end-to-end support for all our stone CNC machinery. Our process includes a pre-sale needs analysis, collaborative R&D for custom solutions, transparent production updates, on-site commissioning and training, and responsive after-sales service for maintenance and parts.

Frequently Asked Questions

How do I build a decision checklist for a CNC stone lathe?

Build a layered checklist covering product, quality, and operational needs.

- Product Needs: Define your primary products (balusters, columns), maximum Ø/L dimensions, and material types.

- Quality Needs: Specify required precision tolerance, surface finish, and the importance of repeatability.

- Operational Needs: Define throughput targets, shift plans, operator skill levels, and your budget for Total Cost of Ownership (TCO).

Which configuration (vertical/horizontal; PLC/CNC) fits my factory?

Map the machine's structure to your product geometry and its control system to your work mix.

- Structure: Horizontal for long parts (columns), Vertical for heavy, large-diameter parts.

- Control System: PLC for repetitive, high-volume tasks; CNC for flexible, custom jobs.

What training & warranty are included ?

A typical package includes a one-year warranty on parts and labor, plus on-site commissioning.

- Training: On-site operator training is included. Inquire about options for extended or advanced training.

- SLA Options: Discuss available Service Level Agreements (SLAs) for support response times and spare parts.

How can I ensure precision repeatability ?

Maintain a rigid machine structure and enforce disciplined calibration and maintenance routines.

- Maintenance SOPs: Follow a strict schedule for tool checks, guideway lubrication, and machine cleaning.

- Program Control: Use test cuts to verify settings and maintain discipline with parameter management to prevent drift.

English

English