Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Understand pad architecture, bond types, grit ladders, and starting RPMs for granite, marble, and concrete with mitigation tips and safety references.

You get more precise, repeatable finishes because diamond pads cut cleanly at controlled RPM and pressure. For your engineering and maintenance teams, this means stable finish quality, fewer passes, and less rework across granite, marble, concrete, and engineered stone. It's a significant upgrade from traditional sanding routes.

Request the technical datasheet and starting parameters for your materials.

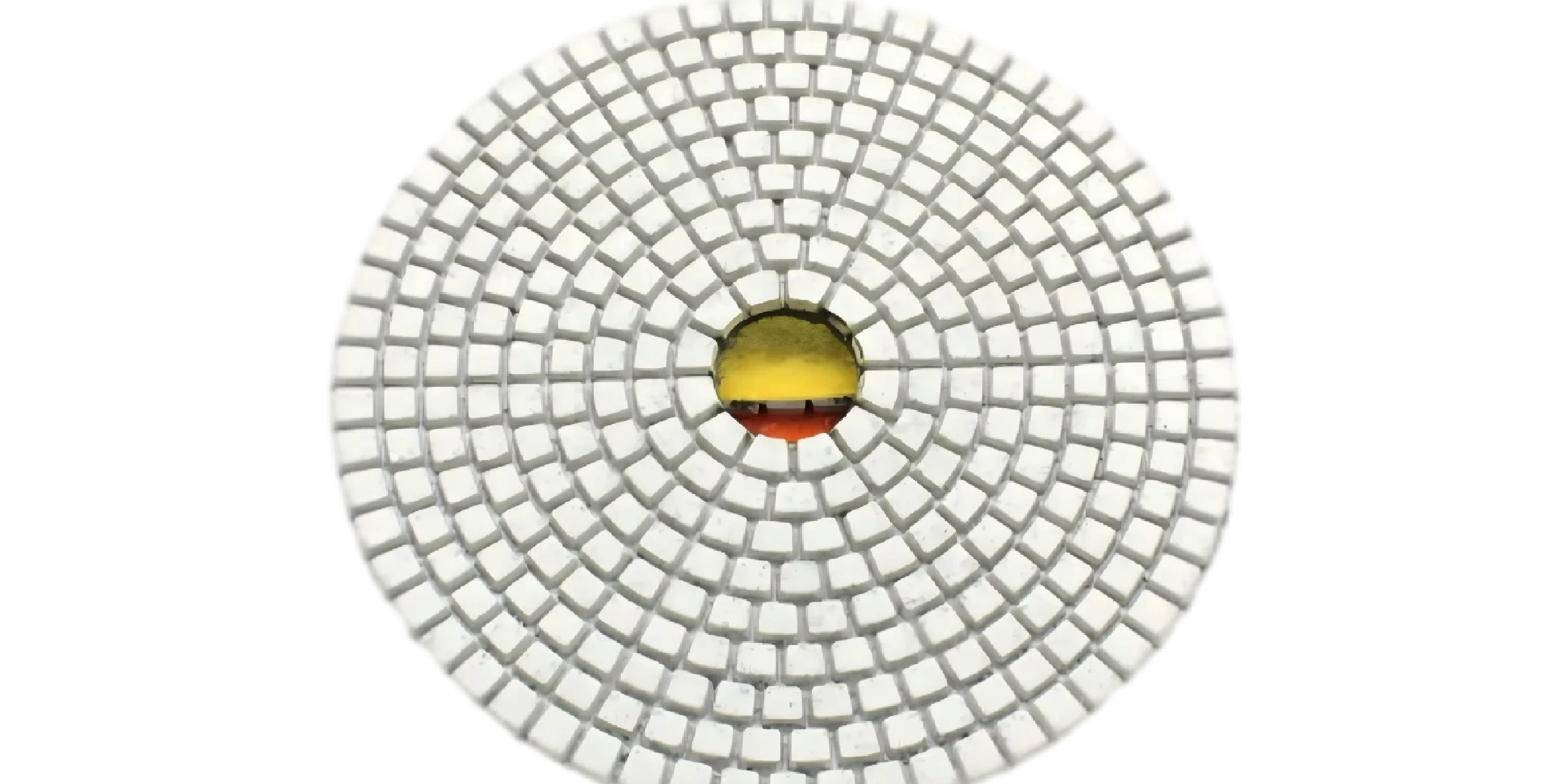

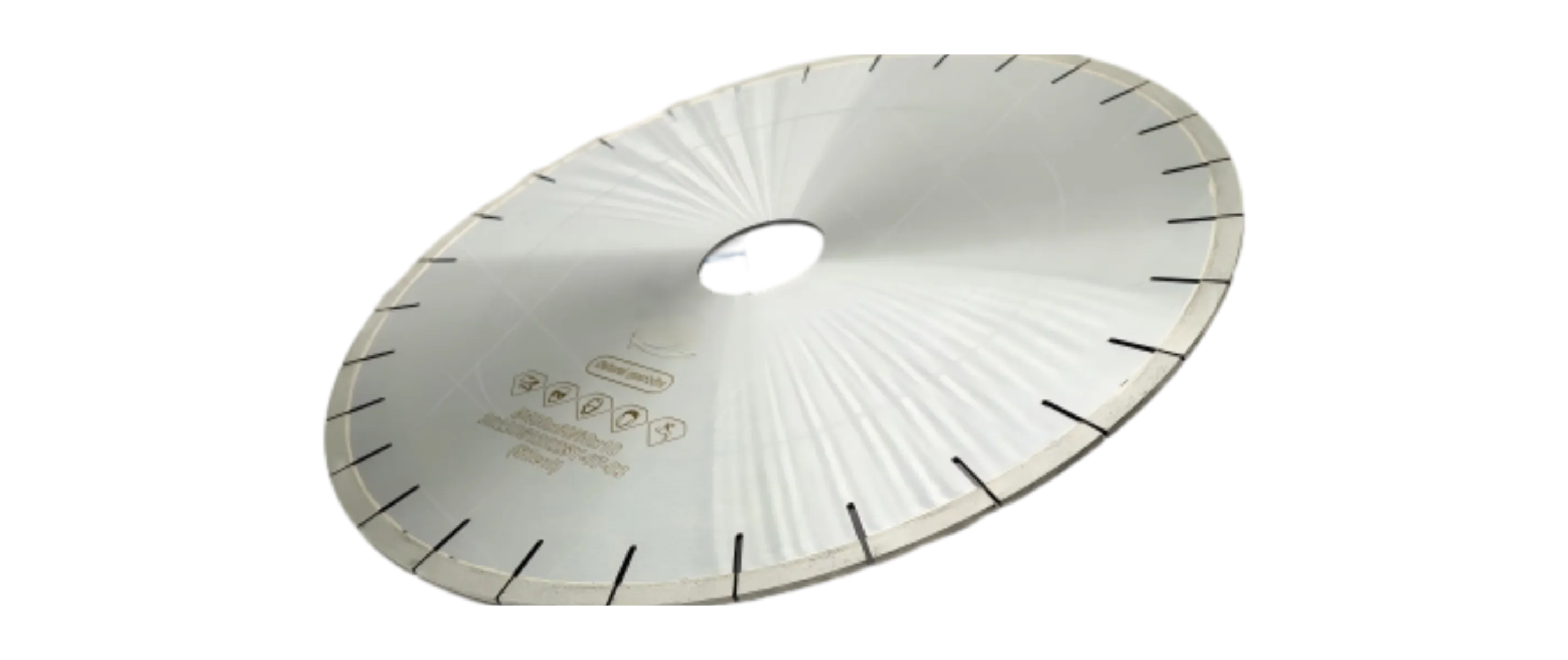

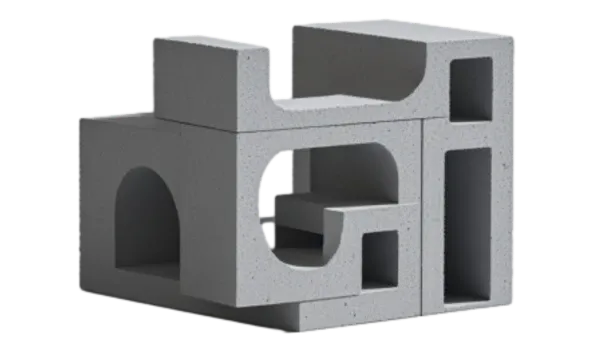

A Diamond Polishing Pad Datasheet reveals that a pad is a layered consumable. It uses industrial diamond particles held in a resin or metal bond to abrade and refine hard materials, with a hook-and-loop backing for quick changeovers.

How Does the Architecture Make Dimoand Pads Better?

The performance of diamond polishing pads is rooted in a few key mechanical and material science principles working in concert. This is what sets them apart from traditional sanding.

- Fewer Passes: Because the diamond particles provide a consistent and aggressive cut, you often need fewer passes to achieve your target gloss, saving time and labor.

- Less Pad Loading: The engineered structure and bond materials are designed to clear slurry more effectively, especially during wet polishing. This means less clogging and a more consistent cut throughout the job.

- Steadier Edge Control: The pad's flexible but stable construction allows it to conform to edges and curves without "digging in," giving you much better control and reducing the risk of faceting.

What's Inside a Diamond Pad, and What Are the Key Parameters?

Understanding each component helps you select the right pad for the job.

- Diamond Grade: The size, quality, and concentration of the industrial diamonds are matched to material hardness (e.g., harder diamonds for granite, different grades for softer marble); you should consult the supplier datasheet for exact values.

- Grit Series: Common ladders run from #50 to #3000. You adjust the starting and final steps based on the initial surface condition and your target gloss level.

- How Does Bond Type Change the Cut?: This is a critical choice you'll make. Resin bonds are for finishing and achieving high gloss, while metal bonds are for aggressive shaping and material removal. Some hybrid options exist for specific applications.

- Backing: A hook-and-loop (velcro) system allows for quick changes. It is important to inspect your machine's backing plate for wear to maintain a secure mount.

- Pad Thickness: A typical pad is a few millimetres thick. Thicker pads can improve conformity on uneven surfaces but may trap more heat during dry runs.

- What RPM Should You Aim For?: For 4-inch/100mm pads, use a moderate, stable RPM per your polisher’s manual. Always prove it on a scrap piece before starting production work.

- Coolant Flow (Wet Mode): Maintain a continuous water feed sufficient to form and carry slurry without pooling, and ensure you have effective drainage.

- BUFF Stage (Finish Beyond 3000#): Black buff and white buff are specialty finishing pads even finer than 3000# grit, used to push the gloss to its maximum on final passes. You should pick black buff for black stone and white buff for all other colors.

What Connectors Do You Use to Mount the Pads?

We also supply pad adapters, or joints, to mount pads securely on your stone processing machines.

- Rubber Joints: These screw onto the machine's thread to connect the pads.

- Single-layer: Thinner and more flexible, making it ideal for edges, corners, and tight turns where you need more maneuverability.

- Double-layer: More stable and rigid, perfect for polishing large, flat surfaces.

- Aluminum Joints: A durable option for general mounting where rigidity is beneficial.

- Pneumatic Adhesive Pad : This type is designed for air polishers and provides quick attach/detach functionality via pneumatic actuation.

How Do You Mitigate Common Failures?

Identifying and addressing common issues quickly is key to maintaining quality and efficiency.

- Glazing: The pad surface becomes shiny and stops polishing. This is often caused by excessive pressure or heat. To fix it, reduce your pressure, dress the pad to expose new diamonds, or switch to wet mode.

- Burn Marks: Discoloration on edges or flat surfaces means there's too much heat. To prevent this, lower your RPM and/or pressure, add wet coolant, and keep the tool in constant motion.

- Pad Loading: Slurry and dust clog the abrasive surface. Increase coolant flow, vacuum between steps, or rinse the pad. Wet polishing is generally better for materials like marble that are prone to loading.

- Chatter/Uneven Gloss: This often points to machine instability or inconsistent pressure. Make sure your tool is well-supported, overlap passes evenly, and check the integrity of the pad backing.

Compatibility, Standards, and Safety

Diamond pads are widely compatible with a broad range of handheld, floor, and shop machines using hook‑and‑loop or standard adapters—so you won’t be locked into one tool family. Safety still comes first: according to the OSHA respirable crystalline silica standard (1910.1053) and the NIOSH Dust Control Handbook, use wet methods or local exhaust to control dust. For practical setup, see the Hand‑held Stone Polisher with Wet Dust Suppression.

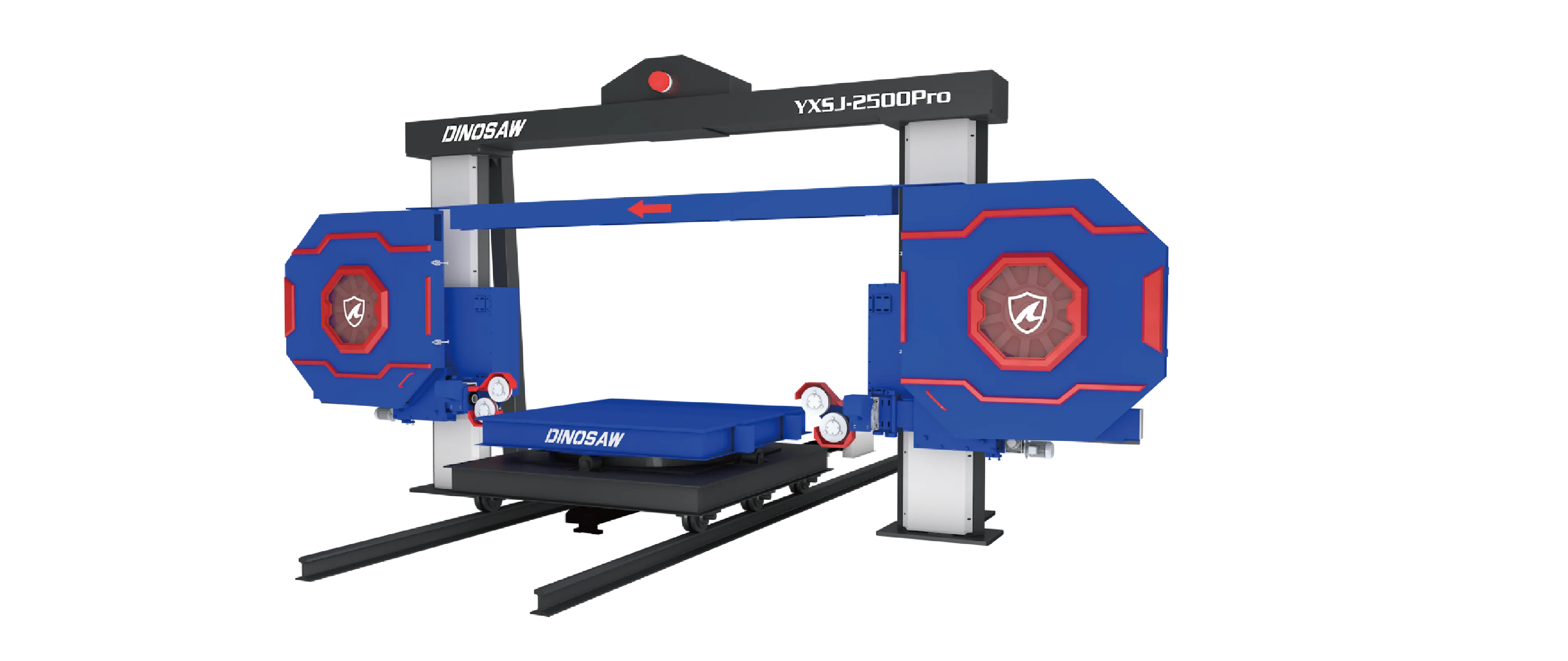

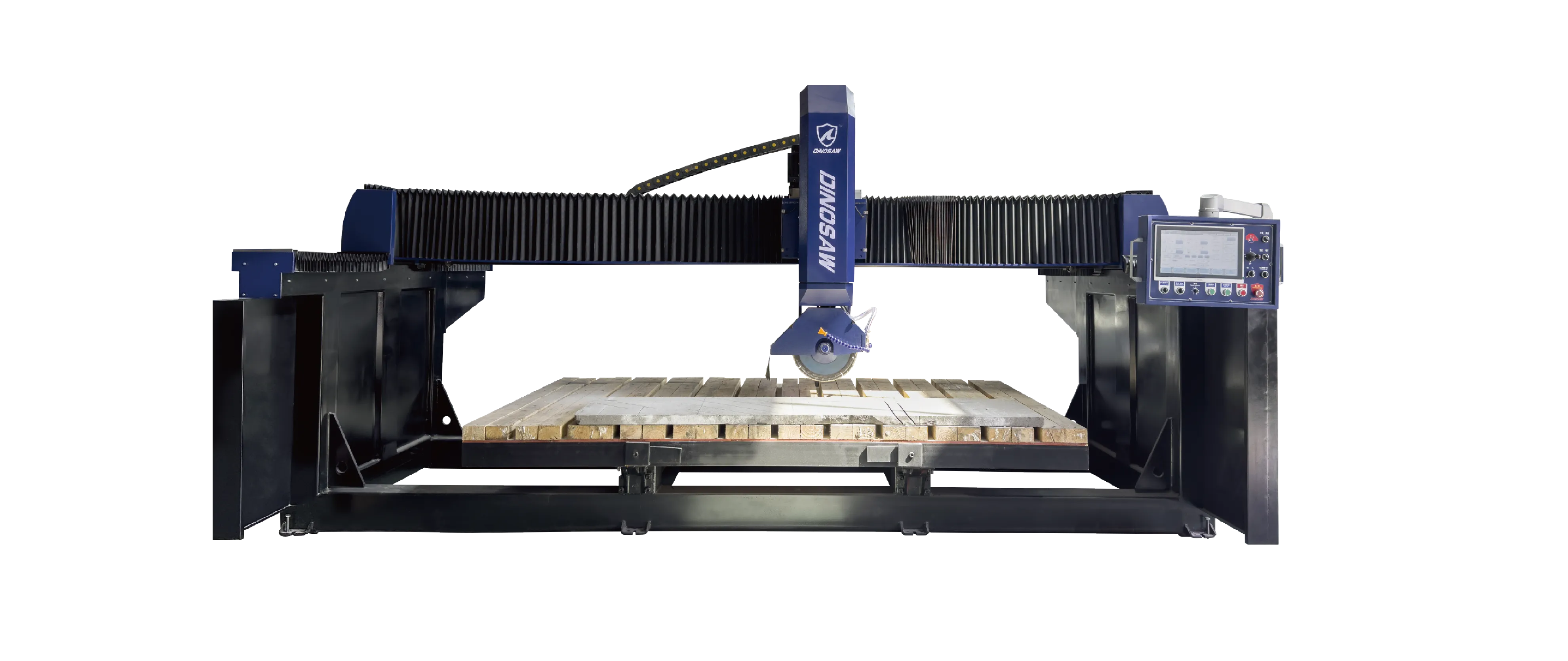

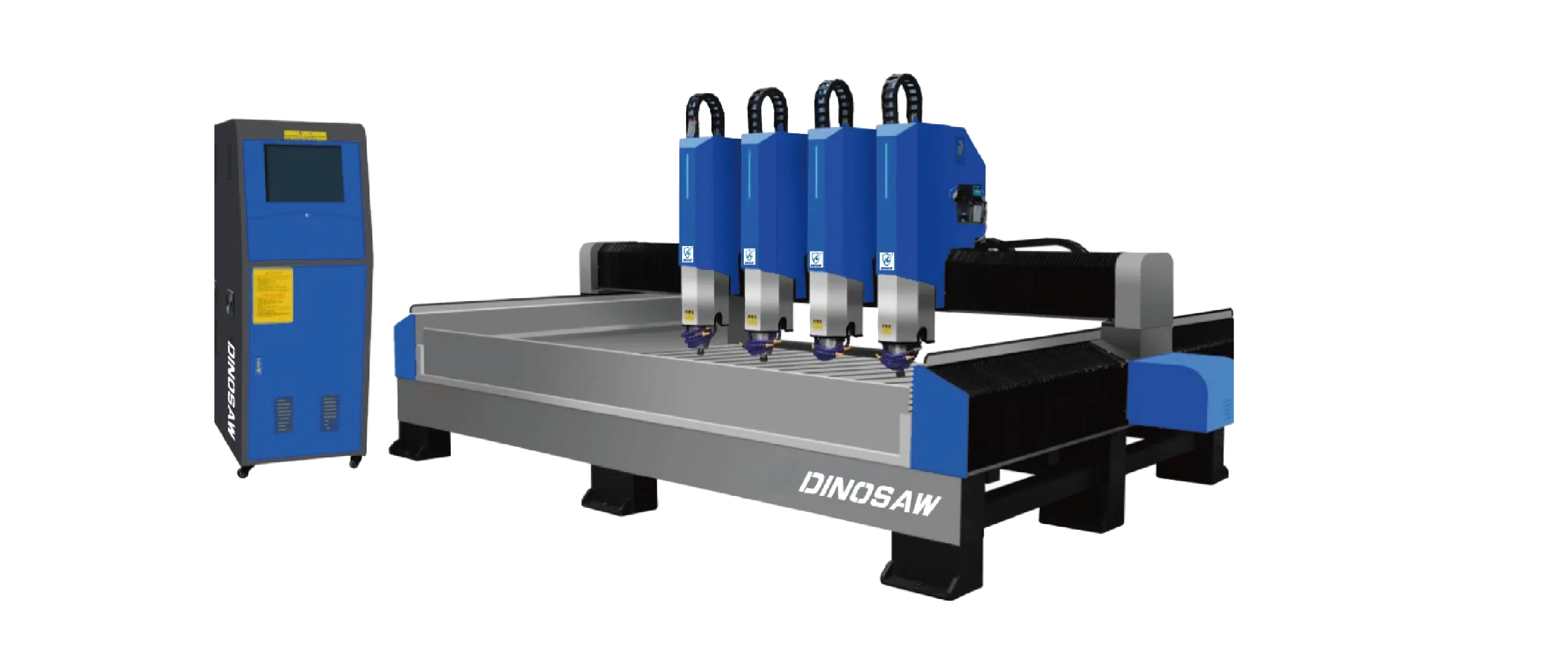

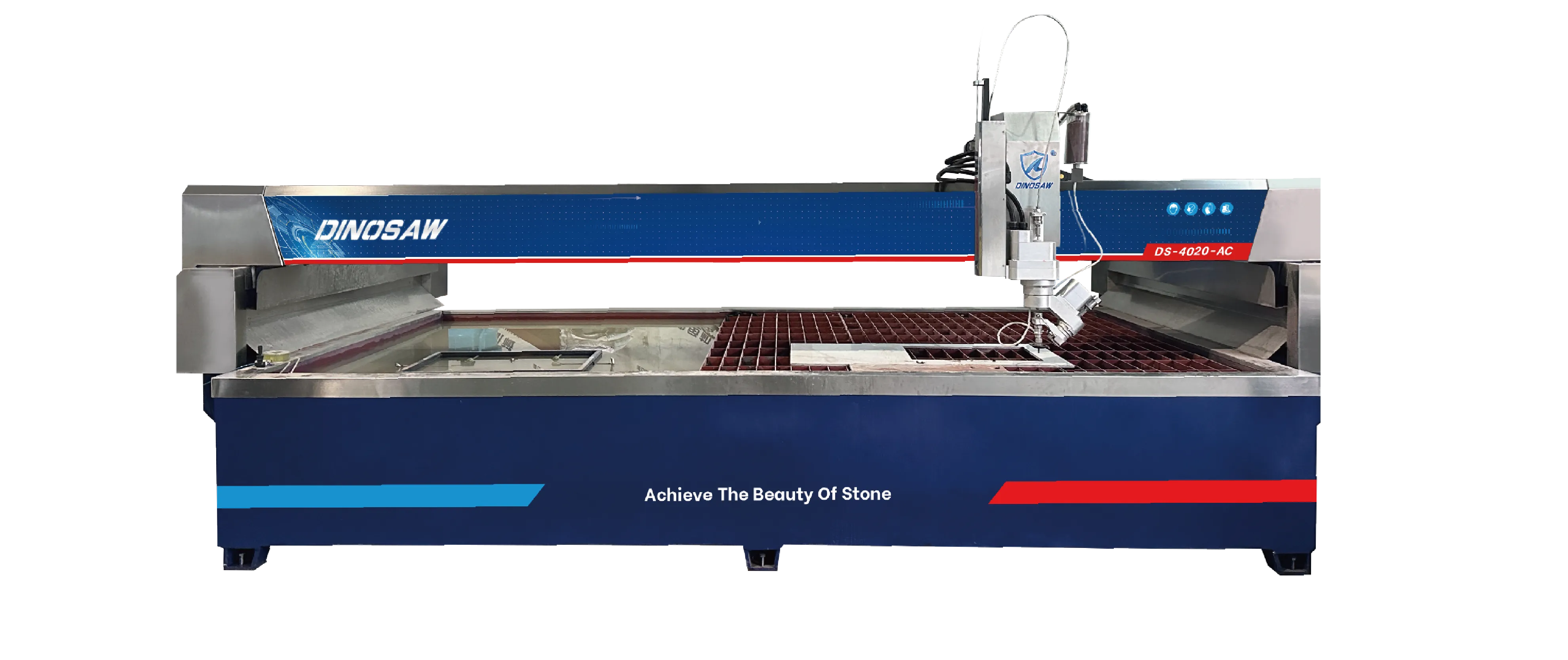

Compatible Machines (examples, not a full list)

- Side-exhaust air polisher

- Rear-exhaust air polisher

- glass & stone edging machine

- automatic polishing machine for slab

- ATC polishing machine

- Floor renovation polisher (planetary/grinder‑polisher)

- Terrazzo floor polisher

- Marble/tile polishing machine

- Swing machine/scrubber with polishing head

- Handheld wet polisher (electric/pneumatic)

If your holder is non‑standard, just match the adapter (rubber single/double layer, aluminum, pneumatic adhesive pad) and you’re good to go.

Want us to confirm if your machine fits?

Send us a quick note and we’ll match the right pads/adapters for you in minutes. Share:

- Machine model + brand (e.g., air polisher, planetary, edging/slab/ATC)

- Holder/adapter type (hook‑and‑loop, rubber single/double, aluminum, pneumatic adhesive pad)

- Pad diameter & inner hole (e.g., 4 in/100mm; 16/20/25mm)

- Dry or wet mode, typical RPM range

- Materials you polish (terrazzo, marble, granite, concrete, tile)

We’ll reply with a clean fit recommendation and a grit ladder to start with.

Talk to our team to confirm compatibility now

Frequently Asked Questions

Why should I choose a resin vs. a metal bond for diamond polishing pads?

You should choose resin bonds for finishing and high gloss, as they offer a more forgiving contact. Use metal bonds for faster material removal and longer wear life, making them best for initial shaping.

What causes glazing and how do I prevent it?

Glazing happens when heat and pressure from your tool polish the pad's surface instead of the workpiece. You can prevent it by reducing pressure, lowering the RPM, or switching to a wet polishing mode to keep things cool.

What grit steps should I choose for granite vs. marble?

For granite, you can often start with a coarser grit (#50–#100) for shaping. With marble, you should start with a mid-range grit (#200) and use wet polishing, as it's a softer material that needs protection.

Can I run pads dry on granite edges?

Yes, but you need to be careful. Monitor the heat and dust very closely. Keep the tool moving and use lower pressure, and be ready to switch to a wet process if you see any signs of burn marks.

Should I pre-wet marble surfaces?

Yes, pre-wetting helps. It aids in slurry formation and reduces initial heat buildup. For the best gloss on marble, you should maintain a continuous flow of coolant and ensure uniform coverage throughout the process.

What are the signs a pad should be retired?

You should retire a pad if it shows persistent glazing that can't be dressed, if the hook-and-loop backing begins to delaminate, or if it provides an uneven cut after being cleaned. Using a worn-out pad is a sure way to introduce defects into your finish.

Summary

Diamond polishing pads give you a systematic path to precision finishes. By controlling the key variables—grit ladders, bond selection, RPM, pressure, and coolant—and adhering to critical silica safety practices, you can achieve uniform gloss with fewer passes and lower rework. This is a core competency of the Top 10 Best Stone Cutting Machine Brands for Stone Processing.

English

English