Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

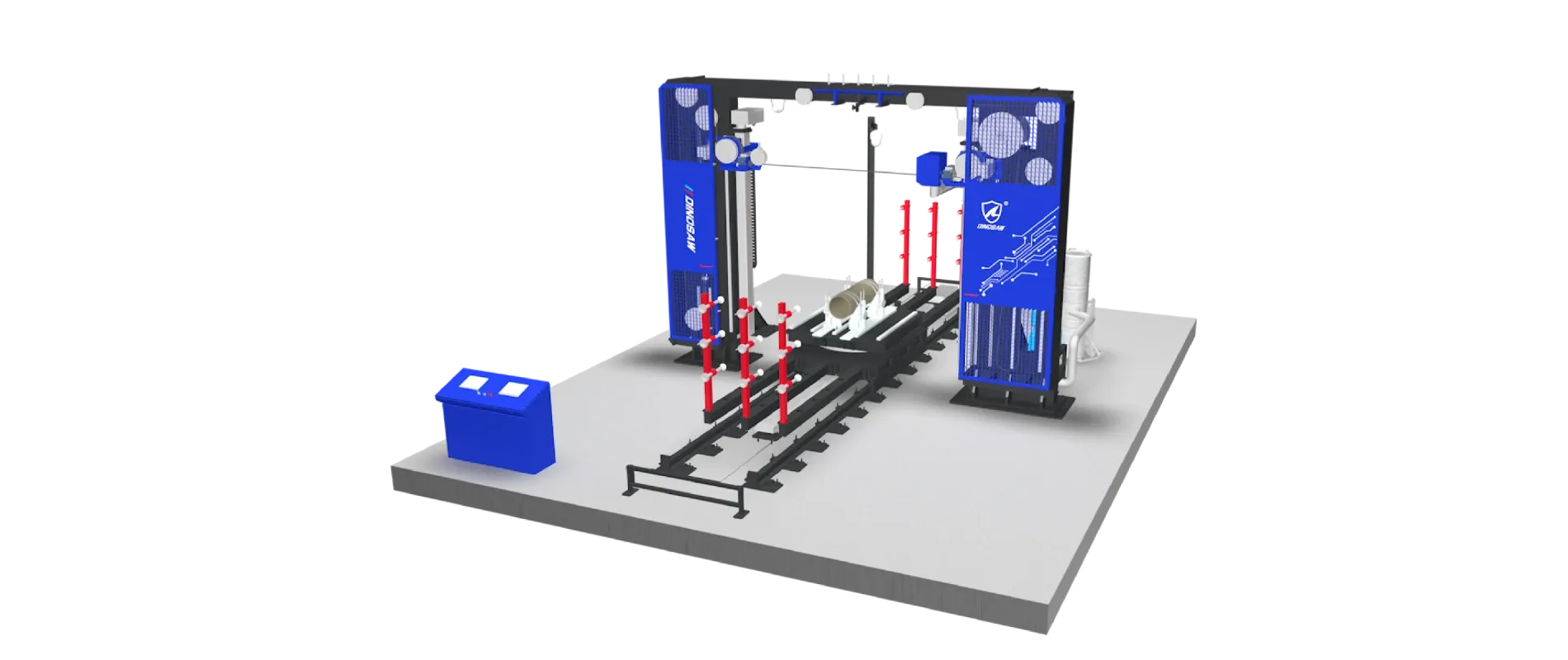

Your complete guide to selecting a CNC diamond wire saw. Compare models, understand key decision drivers, and find the right machine for your application.

Which CNC wire saw should you choose?

- Decide by job: large blocks, intricate columns, or high-precision parts.

- Specify axes, frame rigidity, controller, and motor (15 kW; 22 kW for very hard materials).

- Use the if–then tree to match scenarios and de‑risk procurement.

If-Then Decision Tree: Matching the Machine to Your Job

Start here for a quick way to find a suitable machine based on your primary workload.

Use this decision tree for a practical approach to CNC wire saw selection. Find your scenario and see our recommendation.

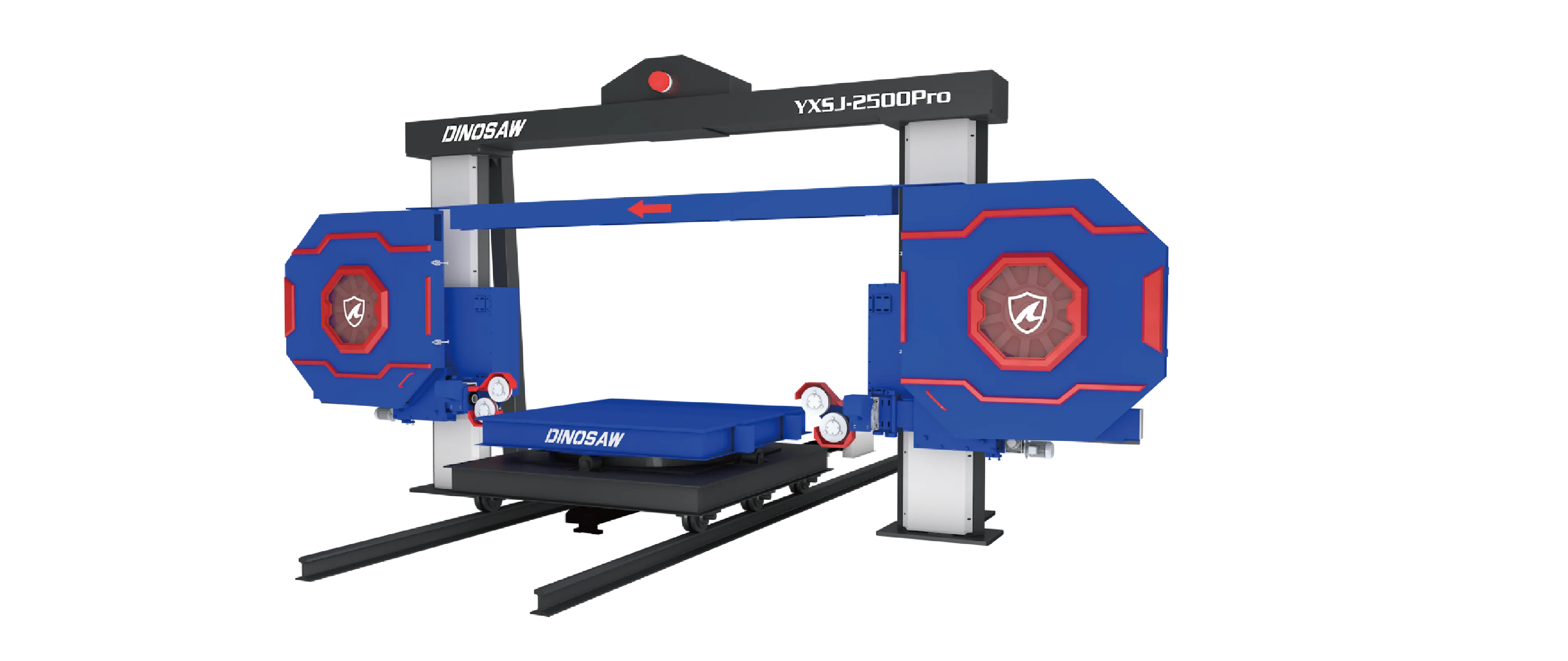

IF your primary work is cutting large granite or marble blocks for construction...

THEN prioritize a machine with a large worktable (e.g., >3m x 2m), a powerful main motor (15 kW is standard, but consider 22 kW for very hard materials), and a robust tensioning system to handle thick, hard materials. Start with a coarse diamond wire (40/50 mesh) for faster cutting.

Risk Note: Underpowered machines will struggle, leading to slow cuts and frequent wire breaks.

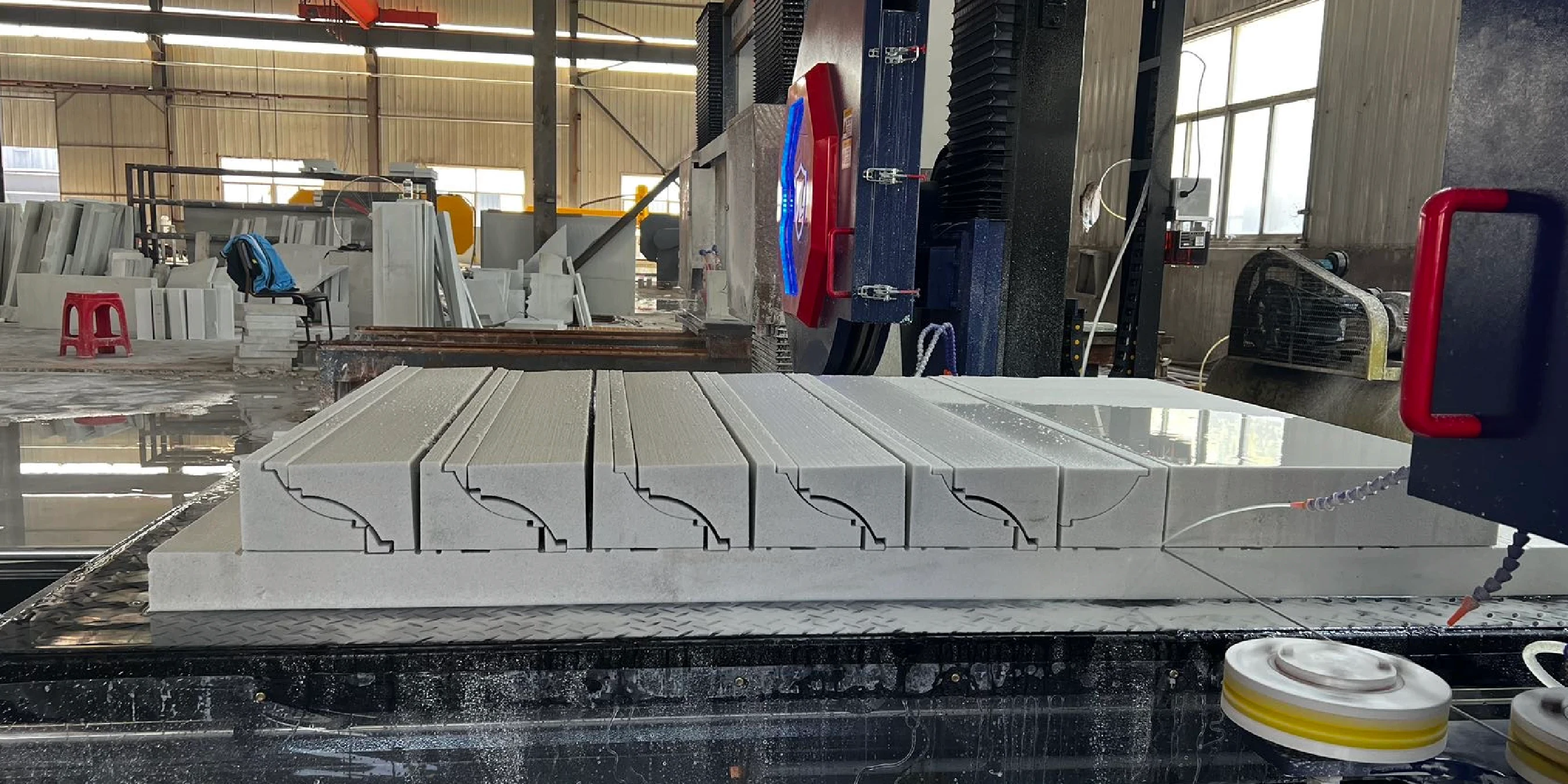

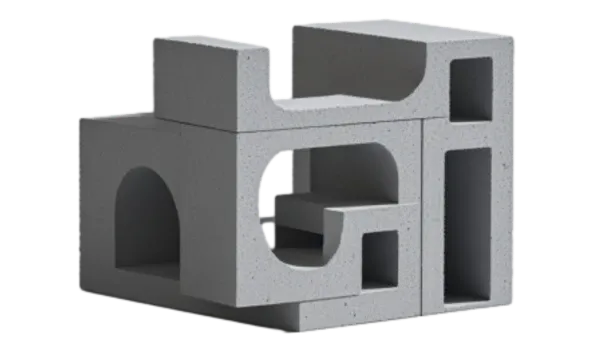

IF you need to produce intricate architectural elements like Roman columns or complex moldings...

THEN a 5-axis CNC wire saw machine is your only viable option. Look for a controller with advanced interpolation capabilities. Start with a medium-grit wire (50/60 mesh) to balance speed and finish.

Risk Note: A 3- or 4-axis machine cannot produce these complex geometries, limiting your market.

IF your focus is on high-precision, small parts made from expensive materials like quartz or silicon...

THEN look for a machine with a highly rigid frame, high-resolution encoders, and a fine-diameter wire (e.g., <1mm). Precision is more important than speed.

Risk Note: A less rigid machine will introduce vibrations, leading to micro-fractures and wasted material.

IF you are a monument/tombstone shop aiming for custom shapes and engravings...

THEN a versatile 4- or 5-axis machine is ideal. Software ease-of-use is critical for creating custom designs quickly. Start with parameters optimized for granite and marble profiling.

Risk Note: Complicated software can create a steep learning curve, slowing down production.

IF you cut soft, abrasive materials like foam ceramics or refractory bricks...

THEN a high-speed machine with excellent dust collection is necessary. The wire does not need to be as robust, but the guide wheels must be well-sealed.

Risk Note: Inadequate dust/slurry management will cause premature wear on all moving components.

IF your budget is tight and you only need to perform simple curved cuts on slabs...

THEN a basic 3-axis model or even a high-quality used CNC wire saw could be an option. Focus on build quality and parts availability.

Risk Note: A used machine may have hidden wear and lack warranty, increasing long-term maintenance costs.

CNC Wire Saw vs. Alternatives: A Scenario-Based Comparison

To help you compare routes, here is how a wire saw stacks up against other machines for common jobs.

Deciding between a CNC wire saw and another machine like a bridge saw or waterjet depends entirely on your application.

Scenario: Straight Cuts on Slabs

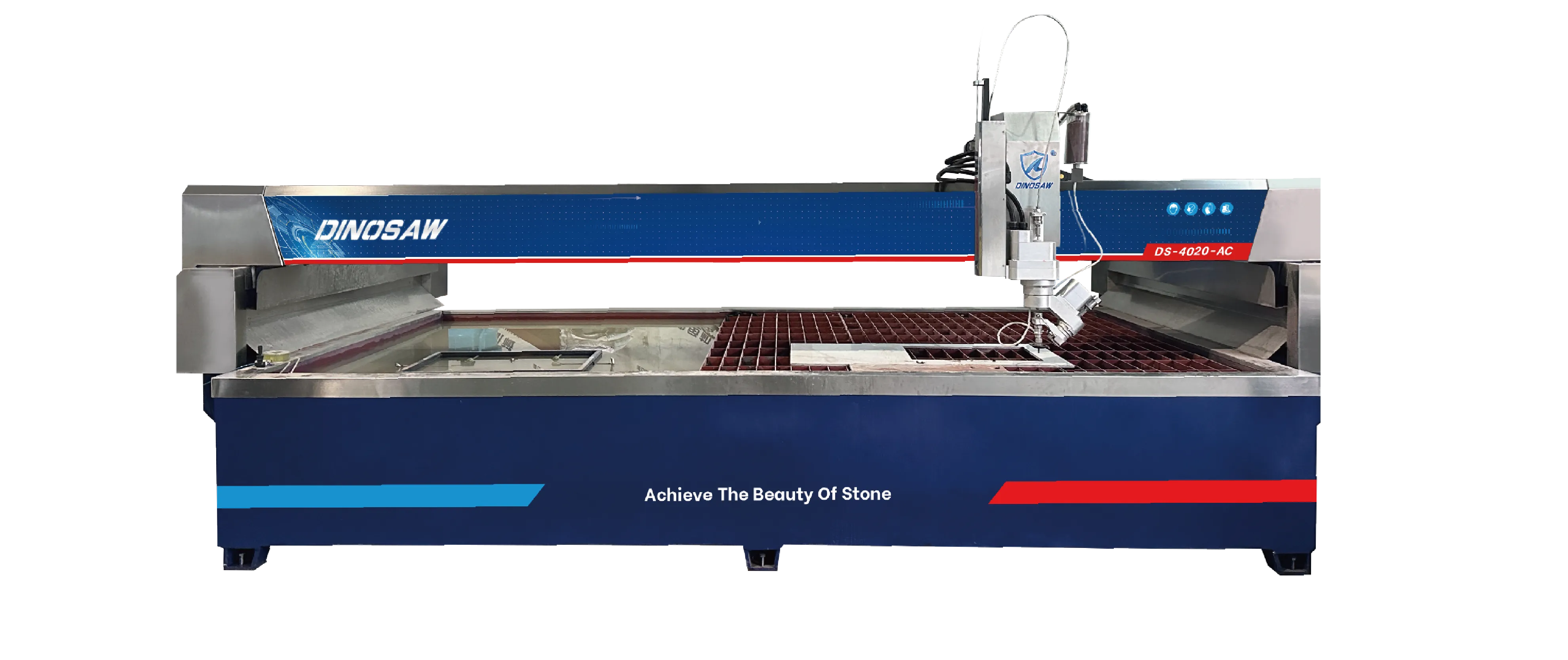

Preferred: Bridge Saw. For simple, high-volume straight cutting of stone slabs, a bridge saw is faster and more cost-effective.

Alternative: CNC Wire Saw. It can do the job perfectly but will be slower. It only makes sense if you also need its contouring capabilities for other jobs.

Not Recommended: Waterjet. Too slow and expensive for this simple task.

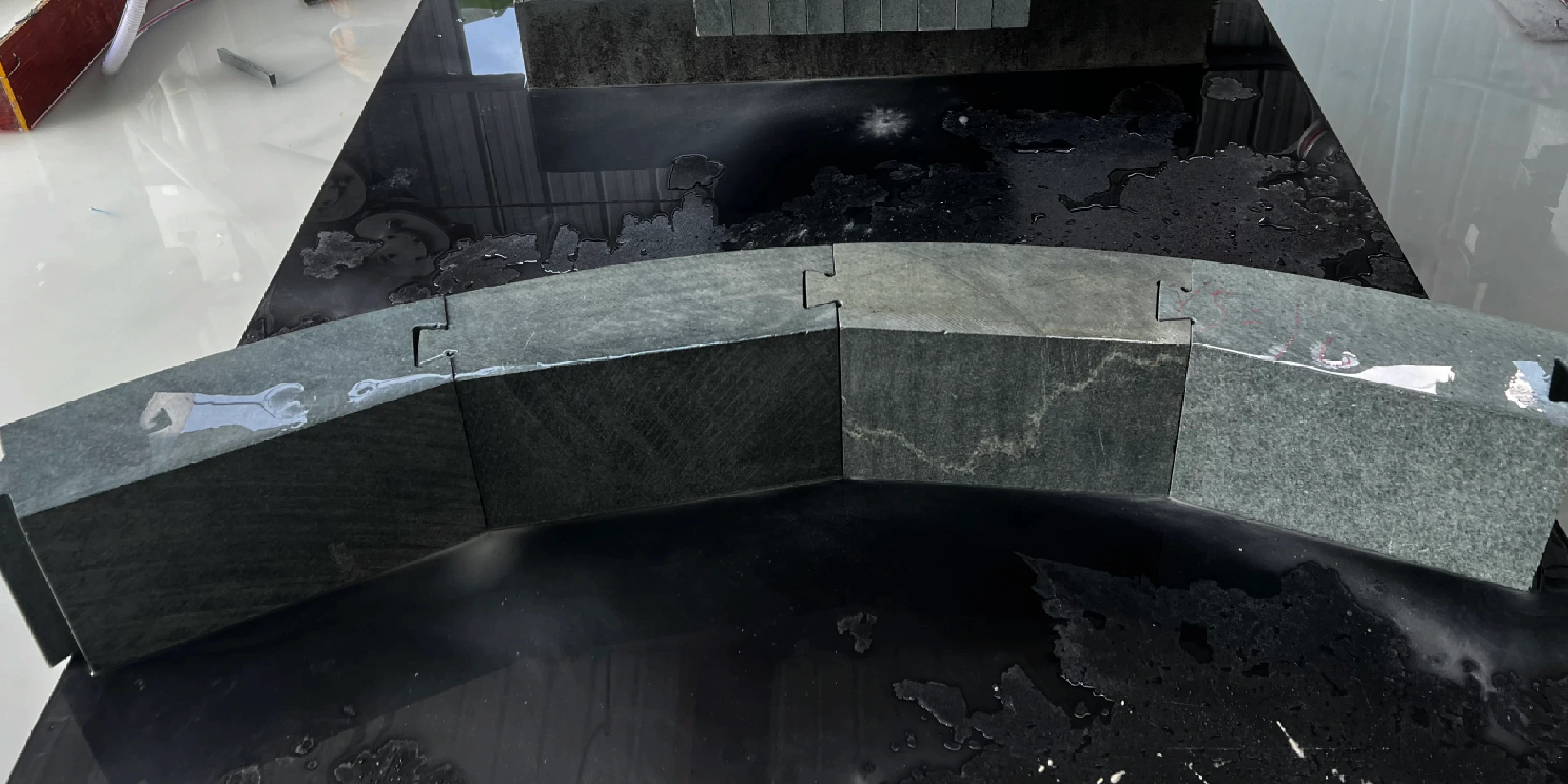

Scenario: Complex 3D Shapes & Curves

Preferred: 5-Axis CNC Wire Saw. Unbeatable for creating complex 3D forms, sculptures, and architectural elements with smooth finishes.

Alternative: 5-Axis Bridge Saw or CNC Router. Can achieve similar shapes but may be slower, have a rougher finish (waterjet), or be limited by tool length and diameter (router).

Not Recommended: 3/4-axis Bridge Saw. It simply cannot perform these cuts.

Key Decision Drivers: What to Look for in a CNC Wire Saw

Once you have a scenario in mind, you can deep-dive on the specifications.

When you start to compare CNC wire saw manufacturers , focus on these core decision drivers that directly impact performance, reliability, and long-term cost of ownership.

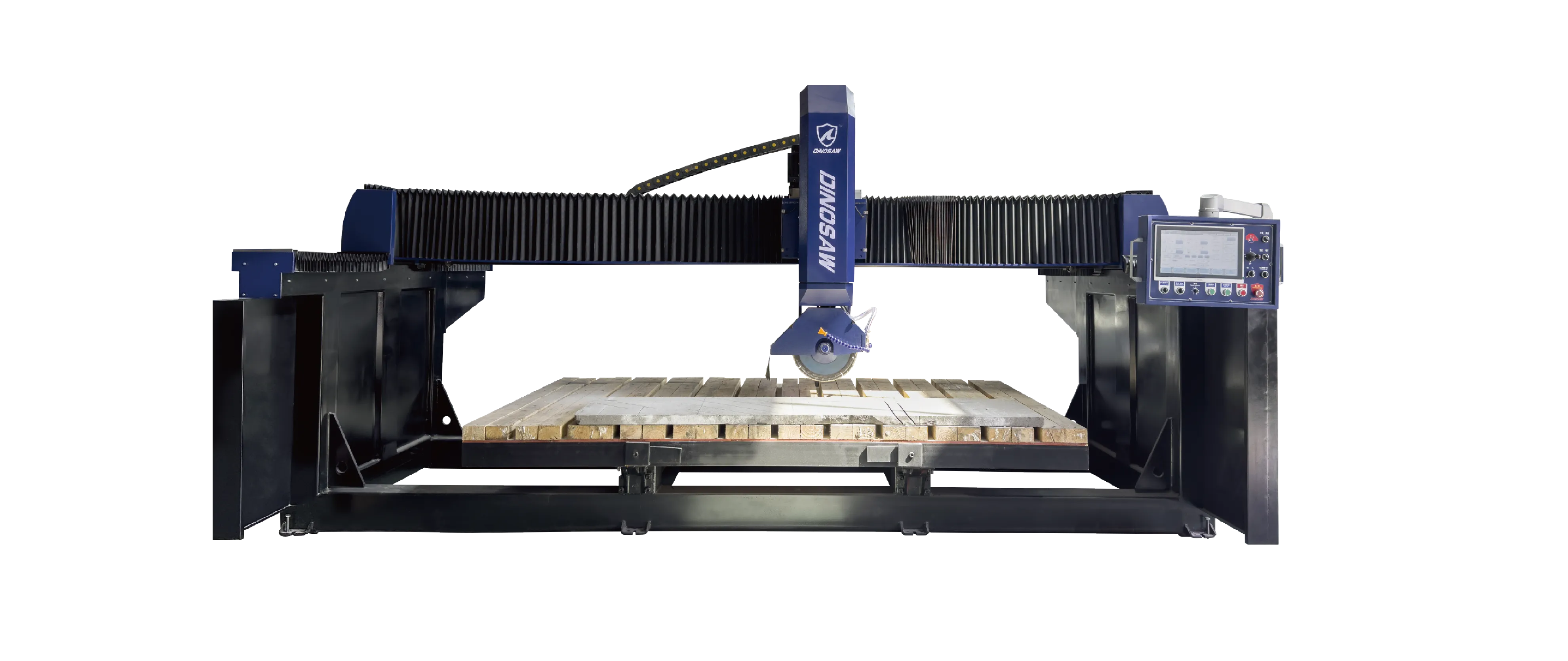

- Machine Structure & Rigidity: The foundation of precision. A heavy-duty, stress-relieved steel frame is non-negotiable. It minimizes vibrations during cutting, which is essential for maintaining accuracy over years of operation.

- Control System & Automation: The brain of the operation. A user-friendly CNC controller that supports standard G-code and file formats (.dxf, .step) is crucial for easy integration into your workflow. Look for features like remote monitoring, automatic tensioning, and alarm diagnostics that enable unattended operation and reduce labor costs.

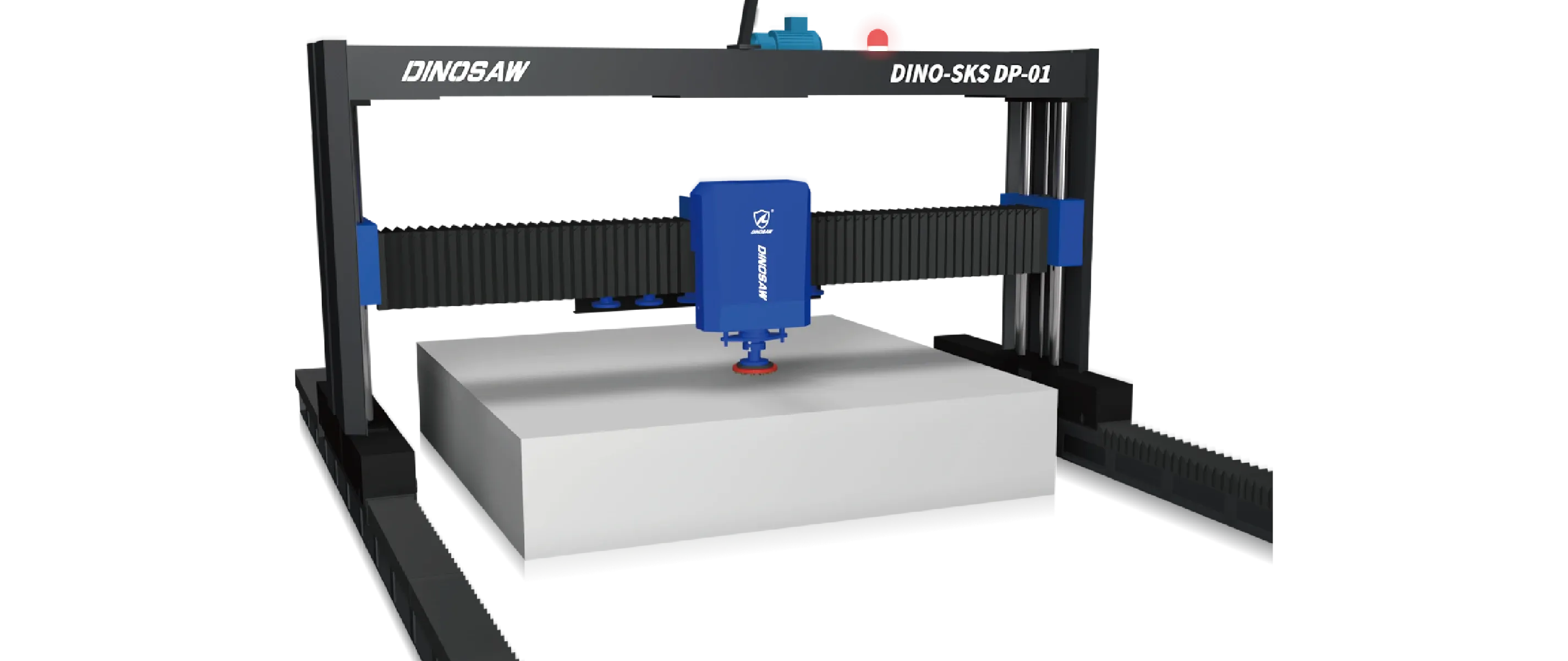

- Application Versatility (Axis Configuration): The machine's capabilities are defined by its axes. A standard 4-axis machine is great for 2.5D cutting, but for creating true 3D shapes, twisted columns, or complex sculptures, a 5-axis CNC wire saw machine is essential. This is a primary differentiator among models.

Key Procurement Topics to Discuss with Suppliers

Finally, discuss these commercial and support topics with potential suppliers.

When you're ready to talk to a CNC wire saw company, go beyond the price tag. These are the topics that determine your long-term success.

- Warranty and After-Sales Support: What does the warranty cover and for how long? Is on-site service available? Clarify response times for technical support.

- Spare Parts Availability: Ask about the lead time and cost for critical spare parts like guide wheels, motors, and diamond wire. A machine is useless if it's waiting for a part.

- Training and Installation: Does the price include on-site installation and operator training? Comprehensive training is vital for maximizing productivity and safety.

- Quality Certifications: Reputable manufacturers should be able to provide evidence of their quality management processes. According to the ISO 9001 standard (https://www.iso.org/iso-9001-quality-management.html), this demonstrates a commitment to quality and customer satisfaction.

- Machine Lead Time: How long from order to delivery? This can impact your project timelines significantly, so get a firm date from any CNC wire saw manufacture.

Frequently Asked Questions

What is the lead time for a new machine?

The lead time for a new CNC wire saw is an important factor for project planning. Standard machine lead time is typically 15-30 days from order confirmation.

For highly customized machines, the lead time could be longer. It's crucial to confirm the specific lead time with us to avoid delays in your production schedule.

Should I buy a new or used CNC wire saw?

Generally speaking, for machines such as CNC wire saws that perform complex and precise cutting, we recommend purchasing a brand new machine.

The decision to buy a new vs used CNC wire saw depends on your budget and risk tolerance. A new machine offers a full warranty, the latest technology, and dedicated support, ensuring reliability.

A used machine can be cheaper upfront but may come with hidden wear, no warranty, and difficulty finding parts. If you have a skilled maintenance team and can thoroughly inspect the machine, a used model can be a viable option, but be aware that the long-term cost could be higher.

What certifications should I look for?

Certifications provide third-party validation of a manufacturer's commitment to quality and safety. For any procurement, you should look for ISO 9001 certification, which indicates adherence to international quality management standards.

If you are in Europe, CE certification is mandatory for safety and compliance. DINOSAW's CNC Wire Saw comes fully certified to help reduce your investment risk.

What are the hidden costs of owning a CNC wire saw?

The total cost of ownership extends far beyond the initial purchase price. The "hidden" costs can include recurring expenses for consumables like diamond wire and guide wheel linings, as well as ongoing costs for electricity and coolant.

You should also factor in the budget for operator training, routine maintenance, and any necessary software licenses. For a complete financial picture, you should review a guide on CNC Wire Saw Machine Prices .

English

English