Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

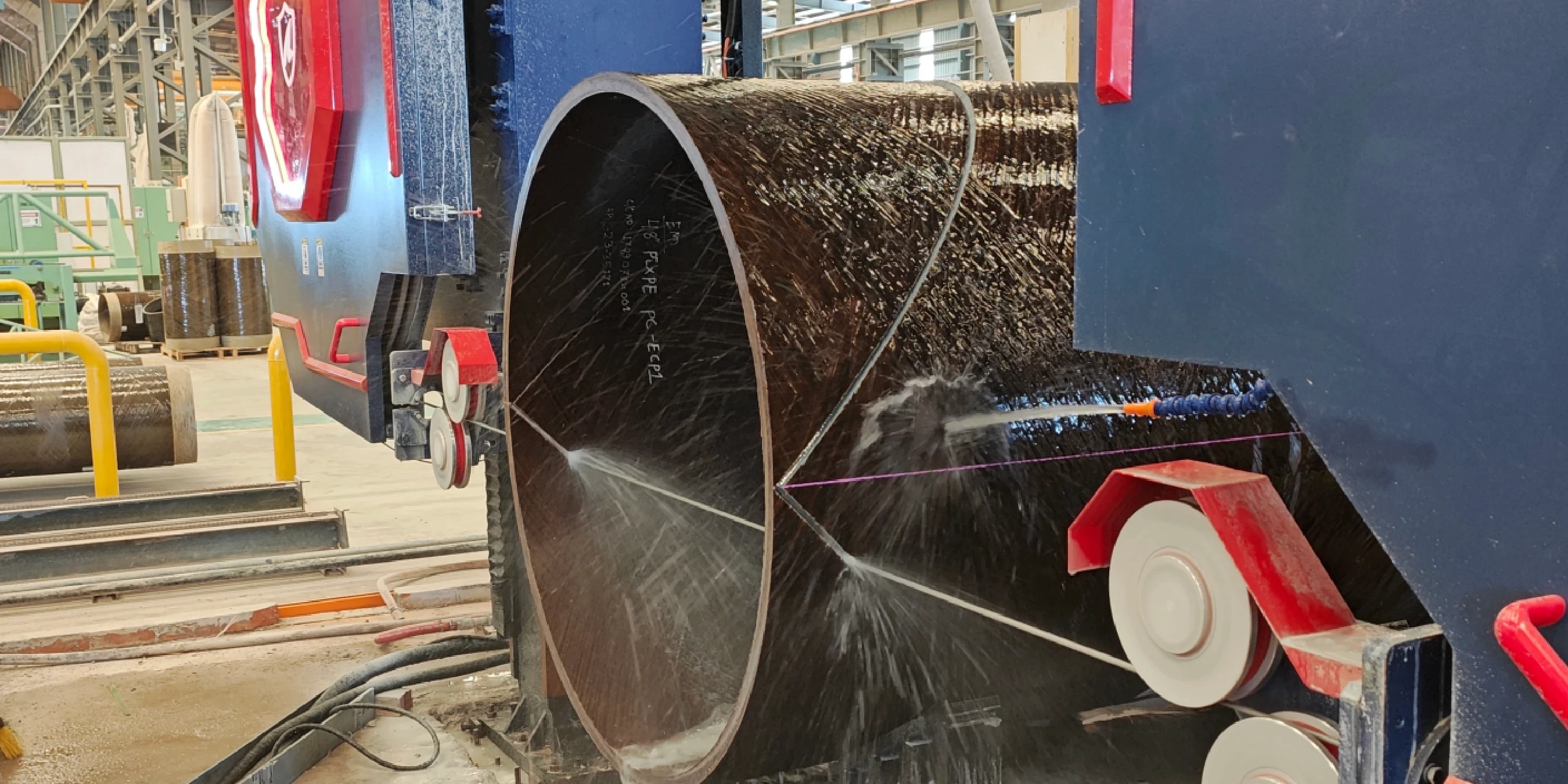

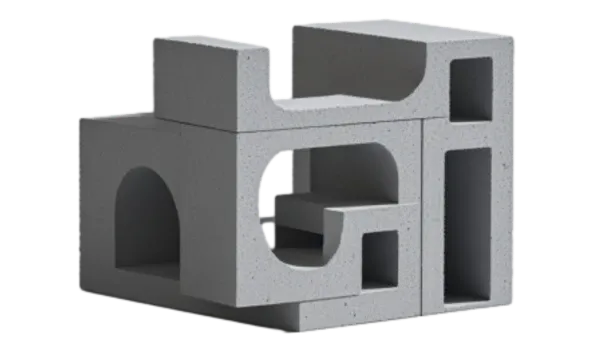

Explore how a CNC wire saw machine unlocks complex cuts in stone, ceramics, and composites. See real-world case studies of CNC wire saw applications and find out if it's right for your shop.

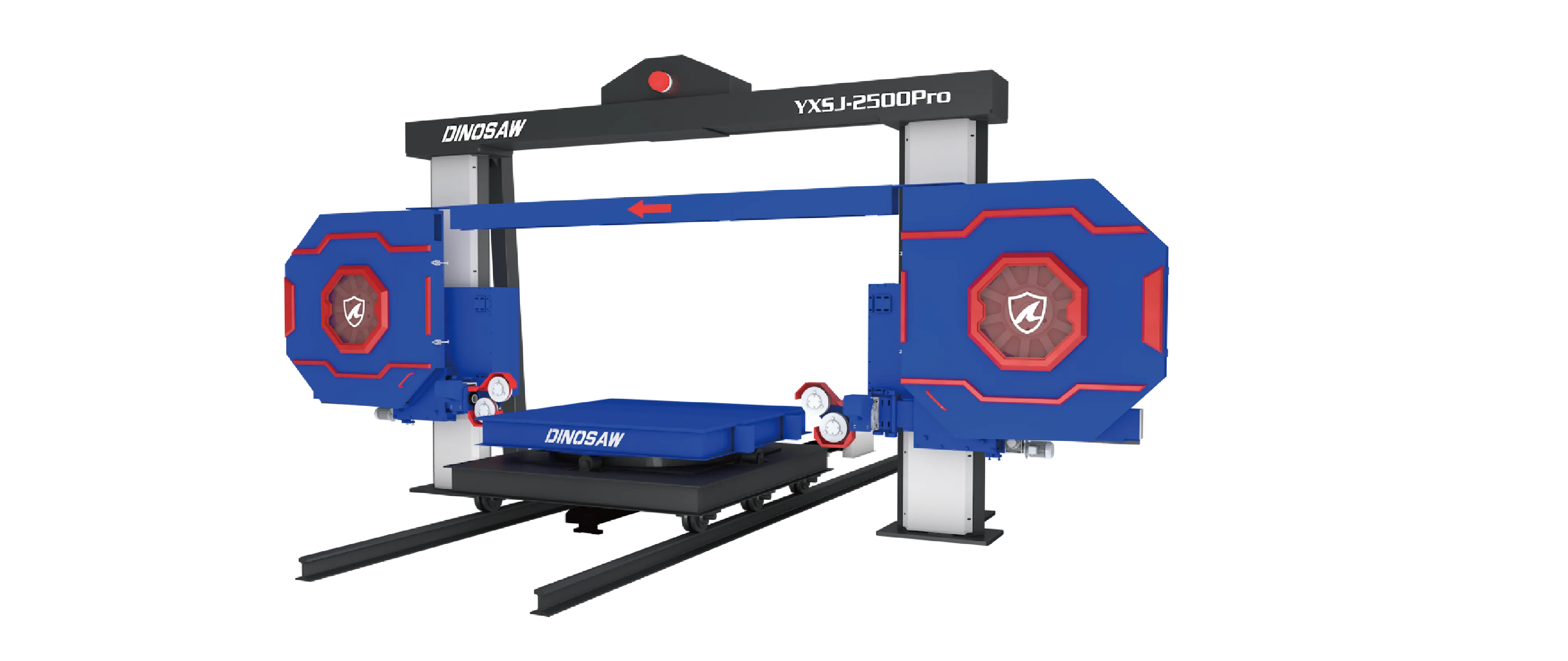

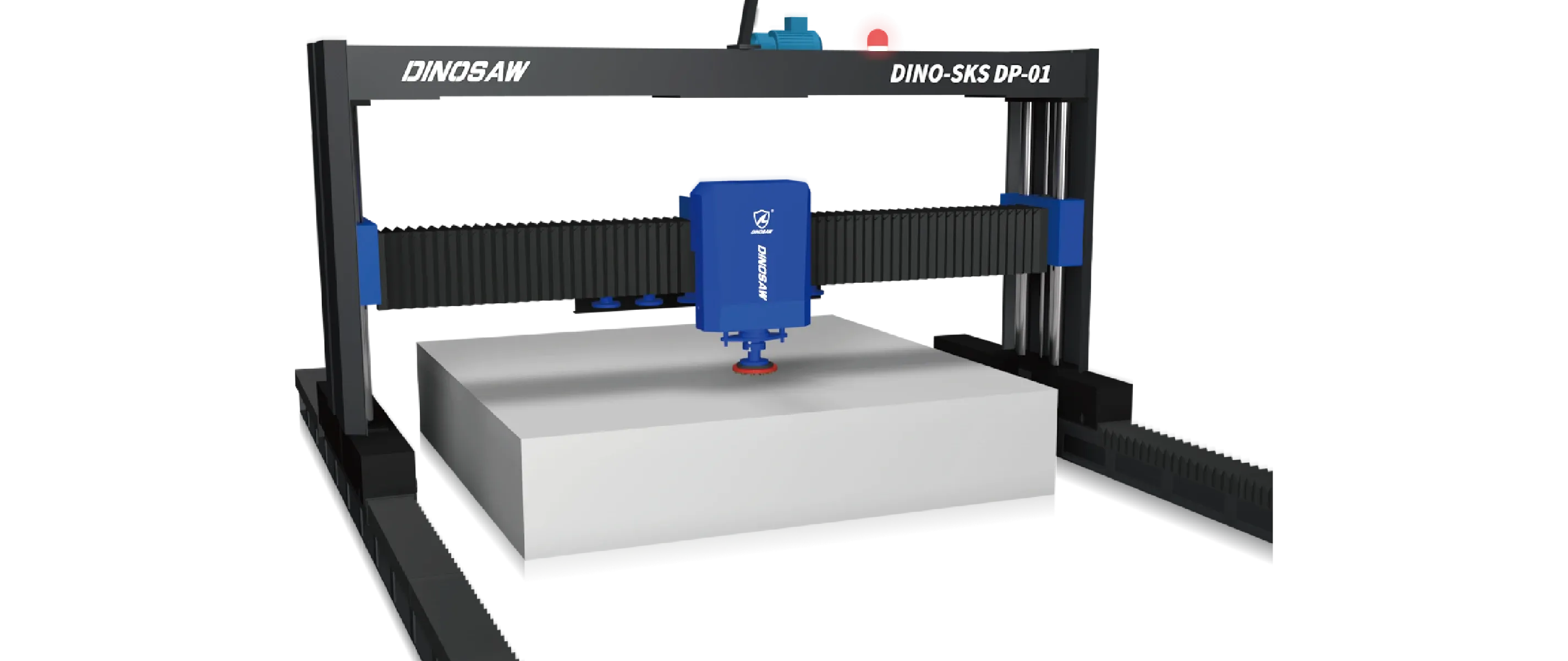

What can this CNC Diamond Wire Saw do for you?

- Take on complex 3D curves and custom shapes with minimal waste.

- Works across stone, foam ceramics, refractory, quartz, and composites.

- Use cases: architectural elements, monuments, thin slabs; see real cases below.

Talk to us about your material and geometry; we’ll map the right wire and parameters for your needs.

Ready to unlock new revenue streams? Schedule a free consultation to discuss your specific material cutting needs.

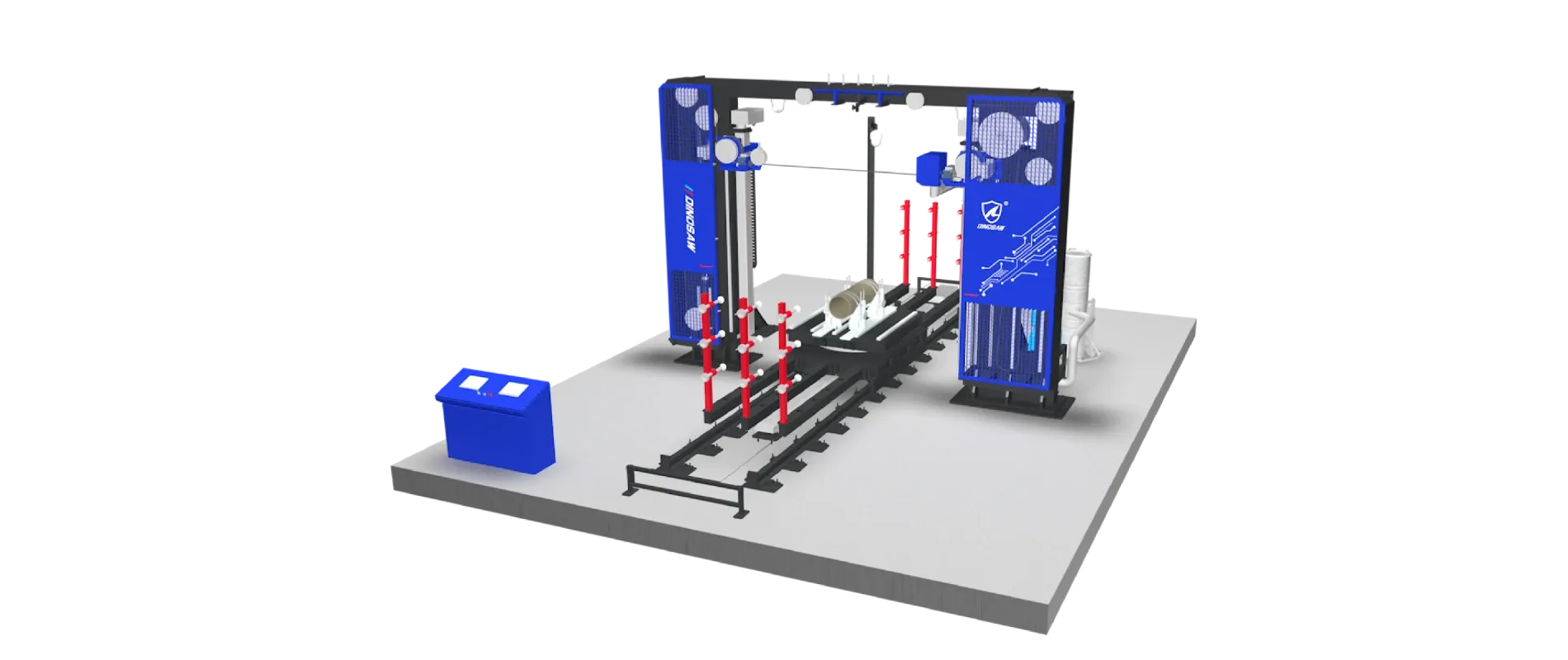

What Can a CNC Wire Saw Do for Your Business?

So, what can a CNC wire saw do that other machines can't? At its core, this machine offers unparalleled versatility and precision.

Unlike traditional saws that are often limited to straight cuts, a cnc wire saw uses a thin, diamond-impregnated wire to perform intricate and non-linear cuts with minimal material waste. This capability opens up a world of new business opportunities for custom shape cutting and industrial materials cutting.

Expanded Material Compatibility

One of the primary advantages of diamond wire cutting is its ability to handle a diverse range of hard and brittle materials that are challenging for other methods. This includes:

- Natural Stone: Effortlessly cuts granite, marble, limestone, and sandstone for architectural and monumental work. The precision wire sawing process is ideal for stone slab cutting and creating detailed profiles.

- Foam Ceramics & Refractory Bricks: Perfect for industrial applications requiring precise shapes from insulation or heat-resistant materials, a task known as refractory brick cutting.

- Quartz Glass & Silicon: Used in high-tech industries for slicing delicate and expensive materials with maximum yield and minimal kerf loss.

- Composites: Capable of cutting carbon fiber and other composite materials without causing delamination, preserving the material's structural integrity.

Advanced Processing Capabilities

The machine's CNC-controlled movement unlocks a variety of high-value processing capabilities that are difficult or impossible to achieve with saws or waterjets. These CNC wire saw applications allow you to command higher prices and enter niche markets.

- Complex 3D Shapes: Create sculptures, decorative columns, and custom furniture with true three-dimensional freedom.

- Intricate Curves and Contours: Produce bespoke countertops, sinuous architectural panels, and artistic inlays that set your work apart.

- Thin Slabs & Veneers: Slice expensive blocks into thin, high-yield slabs, maximizing material value and minimizing waste.

This versatility directly translates to better cost-effectiveness. By handling more jobs in-house and minimizing waste, your investment starts paying for itself sooner.

3 Mini Case Studies: From Problem to Profit with a CNC Wire Saw

Theory is one thing, but results are what matter. Here are three examples of how a CNC diamond wire saw machine solved real-world problems and created new profit centers.

Architectural Elements Cutting

Problem: A Russian contractor was turning down lucrative historical restoration projects because they couldn't replicate complex Roman columns and profiles with their existing bridge saws.Action: They invested in a CNC wire saw specialized for architectural elements cutting.Result: They can now produce intricate architectural elements with high precision, securing profitable contracts. The machine's ability to create curved and twisted columns became a key competitive advantage. Read more in the [Roman Column Production Case – CNC Wire Saw Supports Russian Factory]

Monument Customization

Problem: A tombstone factory in Chongqing faced intense price competition on standard rectangular monuments. They needed to offer highmargin custom shape cutting to stand out.Action: They adopted a CNC wire saw for custom monument customization.Result: The factory now offers fully customized granite tombstones, from curved tops to intricate engraved shapes, commanding a 30-50% higher margin than standard products. Details are available in the [Granite Tombstone Cutting Case – CNC Wire Saw Supports Chongqing Factory]

Foam Ceramics Cutting

Problem: An industrial insulation provider needed to cut complex, custom-fit foam ceramic parts for hightemperature furnace linings, a task their traditional saws couldn't handle without chipping and waste.Action: They implemented a CNC wire saw for foam ceramics cutting.Result: The company reduced material waste by over 20% and cut production time for custom orders by half. This new capability allowed them to service high-value aerospace and industrial clients, boosting profitability on specialized parts.

How It Outperforms Traditional Methods

The core advantages of diamond wire cutting lie in its precision, efficiency, and reduced manual intervention. Unlike bulky blades, the thin wire minimizes kerf loss, saving valuable material. The CNC automation ensures repeatability and accuracy that is simply unattainable with manual methods.

Analysis of the stone processing market shows a clear trend towards automation, with one report projecting a 10.9% annual growth rate from 2025 to 2032 for fully automatic equipment, as it enhances precision and reduces labor costs. Adopting a CNC wire saw positions your shop at the forefront of this trend.

Is This Machine Right for You? Risks & Prerequisites

A diamond wire saw for sale is a significant investment. Before purchasing, consider the following:

- Space and Foundation: These machines require a stable, level foundation and adequate space for operation and material handling.

- Operator Skill: While highly automated, operators need training on CAD/CAM software, machine setup, and safety protocols. Ensure you have, or can train, personnel with these skills.

- Safety and Compliance: Proper machine guarding and safety compliance are essential. Per OSHA 1910.212, guarding must be provided to protect operators from hazards. In the UK, the PUWER regulations mandate safe work equipment. Ensure your facility is prepared to meet these standards.

- Job Pipeline: To justify the investment, ensure you have a consistent pipeline of projects that can leverage the machine's unique capabilities for high-profit CNC projects.

Frequently Asked Questions about CNC Wire Saw Applications

What materials can a CNC diamond wire saw cut?

A CNC diamond wire saw excels at cutting a wide array of hard, brittle, and abrasive materials that are challenging for traditional saws. This versatility makes it the go-to solution for creating complex shapes in everything from natural stone and engineered stone to industrial materials like foam ceramics, refractory bricks, quartz glass, and composites.

The process is particularly effective for materials that would otherwise chip, fracture, or delaminate with conventional cutting methods. However, the choice of diamond wire and cutting parameters must be adapted to each material's specific hardness and desired surface finish.

How much does a CNC wire saw machine cost?

The price of a CNC wire saw machine varies significantly based on several key factors, including its size, axis configuration (e.g., 3-axis vs. 5-axis), motor power, and the level of automation. While it represents a considerable upfront investment, the return is often realized through material savings, reduced labor costs, and the capability to undertake high-margin custom projects.

To accurately assess the financial impact, it is essential to consider the total cost of ownership (TCO), which includes consumables, maintenance, and energy costs. These costs will differ based on the specific model and your production volume.

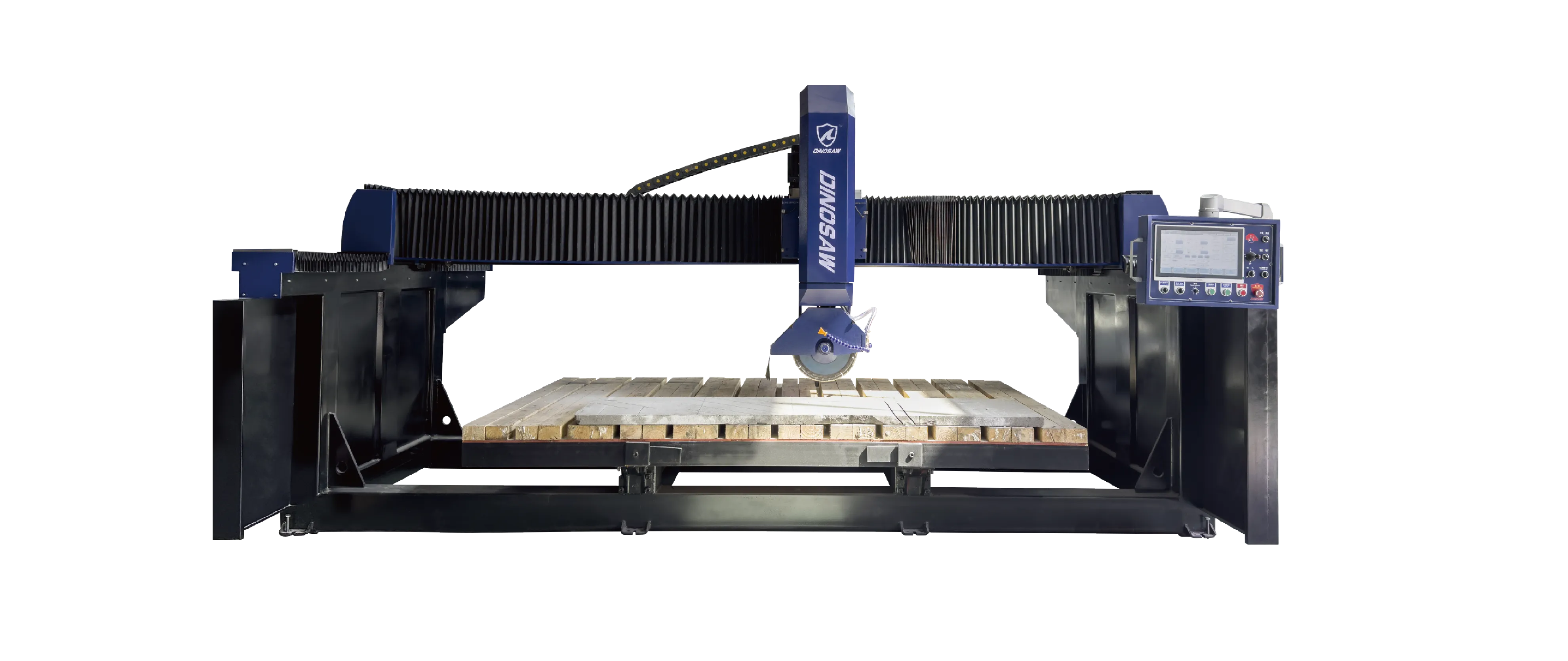

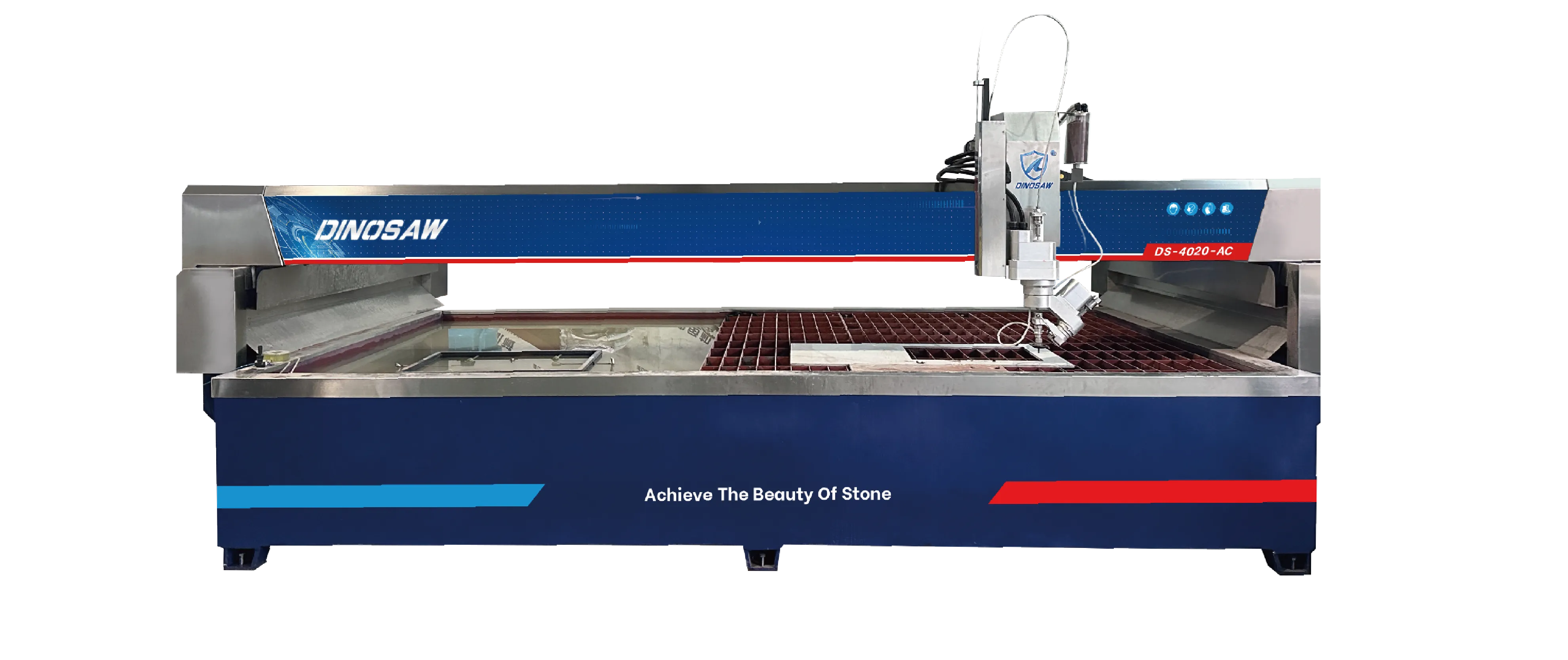

What's the difference between a CNC wire saw vs bridge saw?

The core difference between a CNC wire saw and a bridge saw lies in their cutting capability and intended application. A bridge saw is designed primarily for making fast, straight cuts in 2D, making it the ideal tool for high-volume slab processing and standard countertop production. In contrast, a CNC wire saw provides true 3D cutting freedom, using a flexible wire to create complex curves, contours, and non-linear shapes.

This makes the cnc wire saw vs bridge saw decision critical for business strategy; a bridge saw excels at production efficiency, while a CNC wire saw unlocks artistic fabrication and high-value custom projects. The choice depends entirely on whether your business focus is on volume production or custom, high-margin work. For a deeper comparison, see our Bridge Saw vs. 5-Axis CNC Saw: A Smart Investment Guide.

Do you offer training and support?

Yes, comprehensive training and ongoing support are fundamental to ensuring you maximize the return on your investment, and reputable suppliers provide this as a standard part of the purchase package.

This typically includes on-site installation, commissioning, and operator training that covers the machine's software, safe operation, and daily maintenance routines. After the initial setup, reliable technical support should be available to help troubleshoot issues and maximize machine uptime. The level of support and training can vary between suppliers, so this should be a key point of evaluation. We recommend reviewing our wire saw O&M Handbook to understand the typical operational requirements.

English

English