Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A baluster profiling machine comparison guide. Review decision trees, the total cost of ownership for a stone lathe, and training & warranty info for buyers.

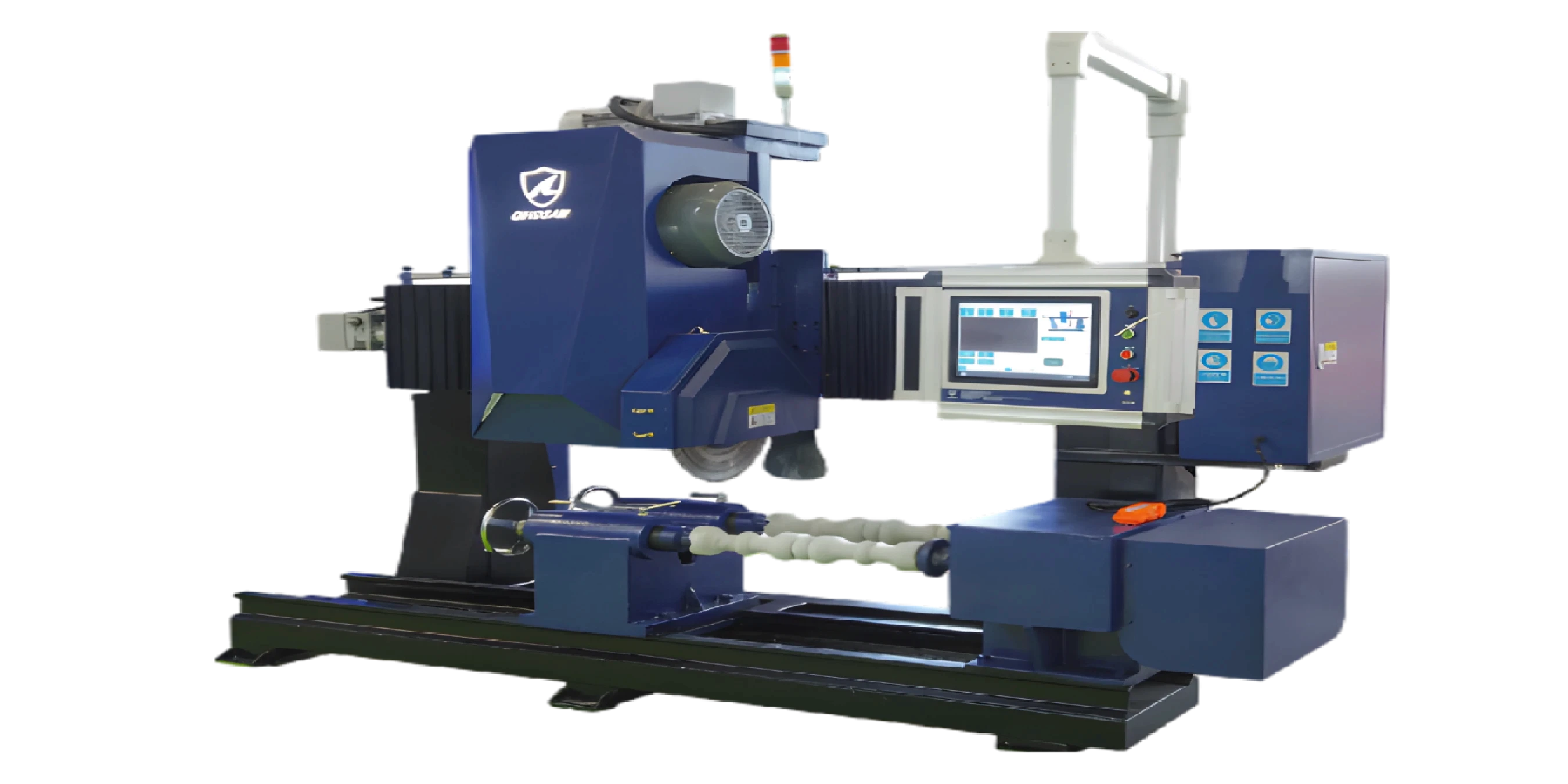

Choosing the right stone CNC turning machine is a critical investment decision. The right choice boosts productivity and profitability, while the wrong one leads to bottlenecks and missed opportunities. This guide provides a clear decision-making framework for procurement managers and engineers. The core principle is simple: choose by geometry, throughput, and finish-then map your stone lathe's configuration to your total cost of ownership.

We'll compare the stone lathe against other common stone CNC machines and walk through a practical selection tree to help you identify the best fit for your specific application, whether it's high-volume baluster production or large-scale column turning.

Get a neutral spec checklist for lathe vs bridge saw vs router to help your evaluation.

Key Decision Dimensions

Before comparing models, evaluate your needs across these key dimensions:

- Geometry & Application: Are you producing primarily cylindrical parts (columns, balusters)? A lathe is purpose-built for this. Or do you need to cut flat slabs? A bridge saw would be more appropriate.

- Material & Size (Ø/L): The material (e.g., granite, marble) and workpiece dimensions directly influence the required machine power and structural rigidity.

- Structure (Vertical vs. Horizontal): A vertical stone lathe is ideal for heavy, large-diameter parts. A horizontal stone lathe excels with long, slender parts like balusters, offering better support to prevent vibration.

- Control System (PLC vs. CNC): A PLC vs CNC stone lathe decision depends on your work mix. CNC offers flexibility for custom, complex profiles, while PLC is a robust, cost-effective solution for simple, high-volume repetitive tasks.

- Throughput & Precision: Define your required output volume and tolerance levels. Automated CNC systems deliver high precision and repeatability, reducing manual error and rework.

- Total Cost of Ownership (TCO): Look beyond the initial purchase price. The total cost of ownership stone lathe includes tooling, maintenance, energy consumption, and labor over the machine's lifespan.

If-Then Selection Tree of CNC Stone Lathe

Use this simple decision tree to narrow down your options:

- If your primary job is high-volume granite column turning, then a heavy-duty horizontal CNC stone lathe with a high-torque spindle is recommended. Risk: Undersizing the machine will lead to slow cycle times and premature wear.

- If you need a marble baluster cutting machine for standard profiles in large batches, then a horizontal PLC-controlled lathe offers the best TCO. Risk: Lack of flexibility if custom designs are later required.

- If you require a customized marble baluster cutting machine for intricate, one-off designs, then a horizontal CNC lathe is essential for programmability. Risk: Higher initial investment and requires a skilled programmer.

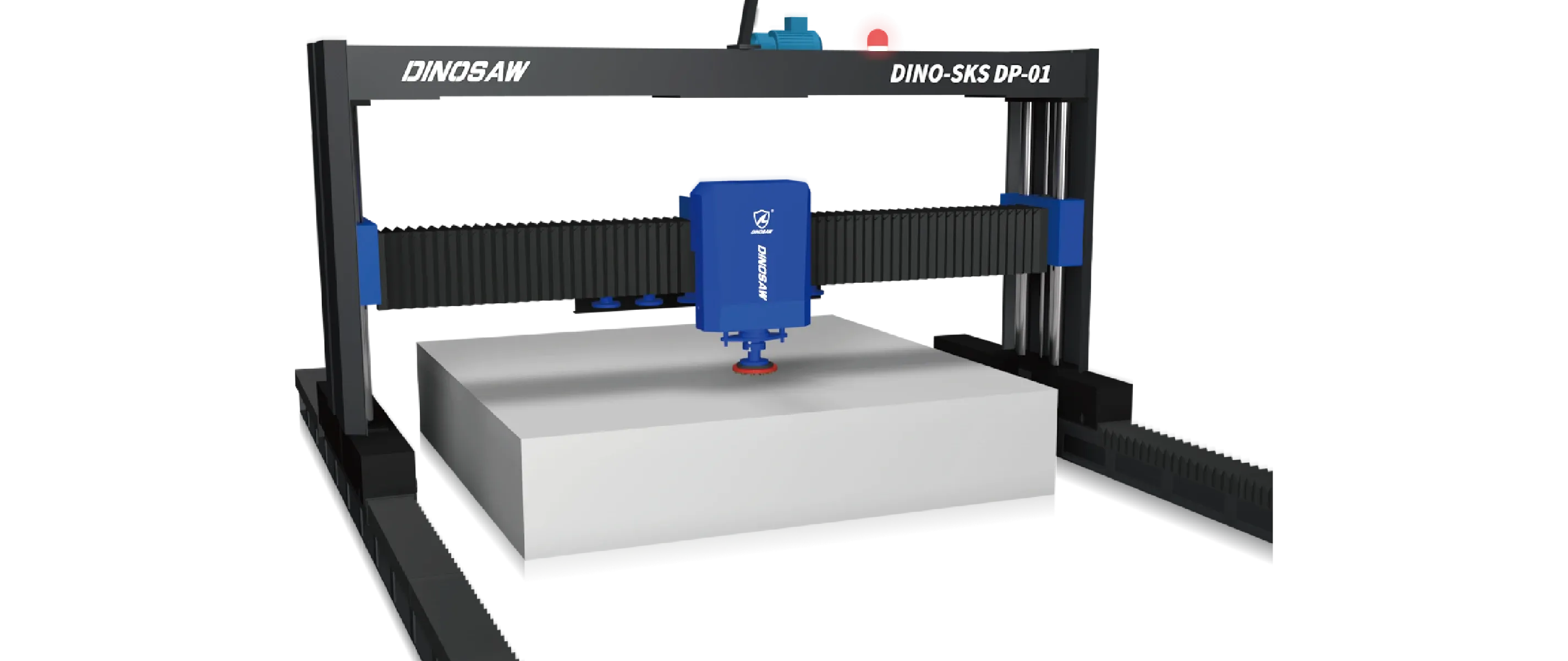

- If you process very large and heavy workpieces for a stone column machine (e.g., >1000mm diameter), then a vertical stone lathe is the superior choice for stability. Risk: Larger footprint and higher ceiling clearance required.

- If you produce batches of identical monument balusters, then a CNC lathe's repeatability ensures every piece is identical, justifying the investment over manual methods. Risk: Changeover time between different profiles must be factored into production planning.

- If you work with thin, brittle sintered stone, then a stone lathe is not recommended. These materials are prone to fracture under turning stress; a waterjet or specialized saw is a safer alternative.

Baluster Profiling Machine Comparison: Lathe vs. Alternatives

While a stone turning machine is purpose-built for cylindrical parts, other machines are sometimes considered. Here’s a neutral comparison for a baluster profiling machine comparison:

- Stone Lathe: Offers the best roundness, precision, and surface finish for cylindrical parts. Its structural rigidity and dedicated tooling are optimized for turning, making it the most efficient choice for columns and balusters.

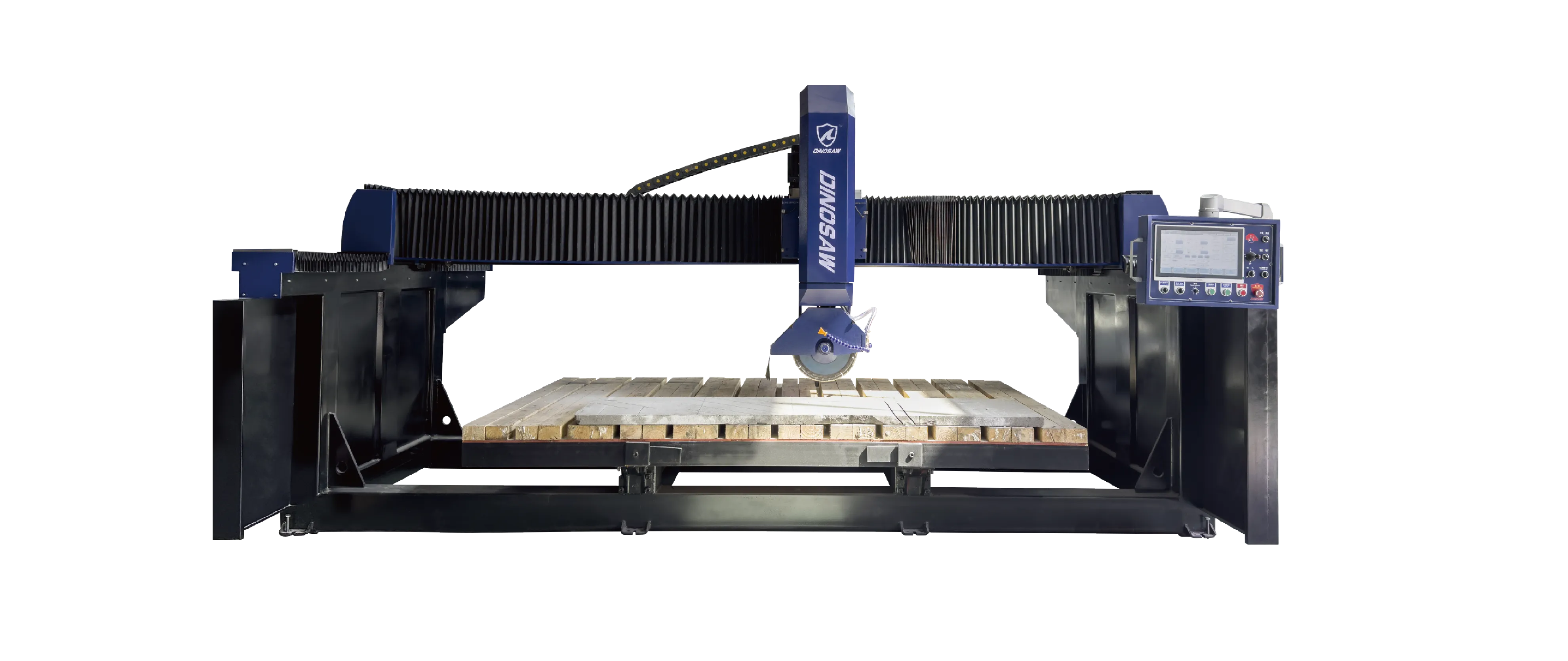

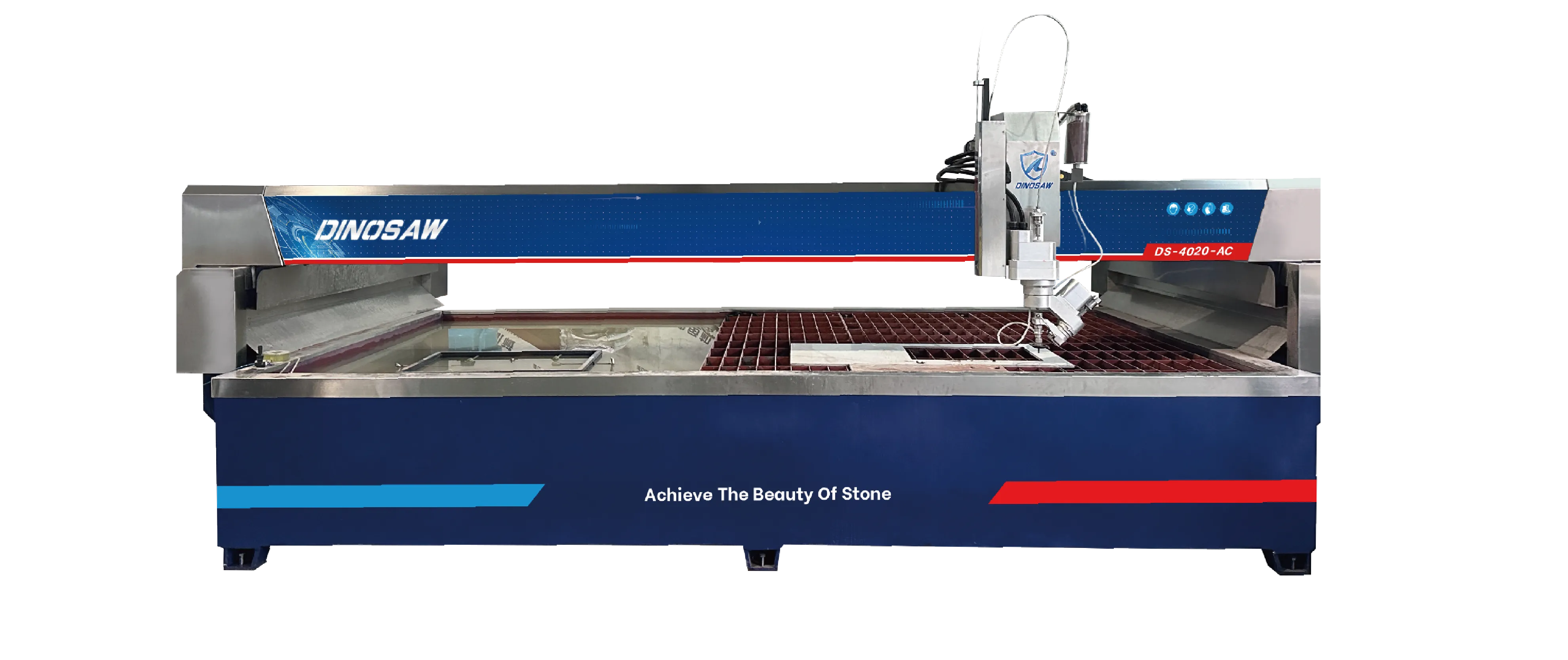

- Bridge Saw (with turning attachment): A bridge saw can be fitted with a rotary axis, but it's a compromise. The setup lacks the rigidity of a dedicated lathe, which can result in vibration, slower cutting speeds, and a poorer finish. It's a viable option for occasional turning but not for dedicated production.

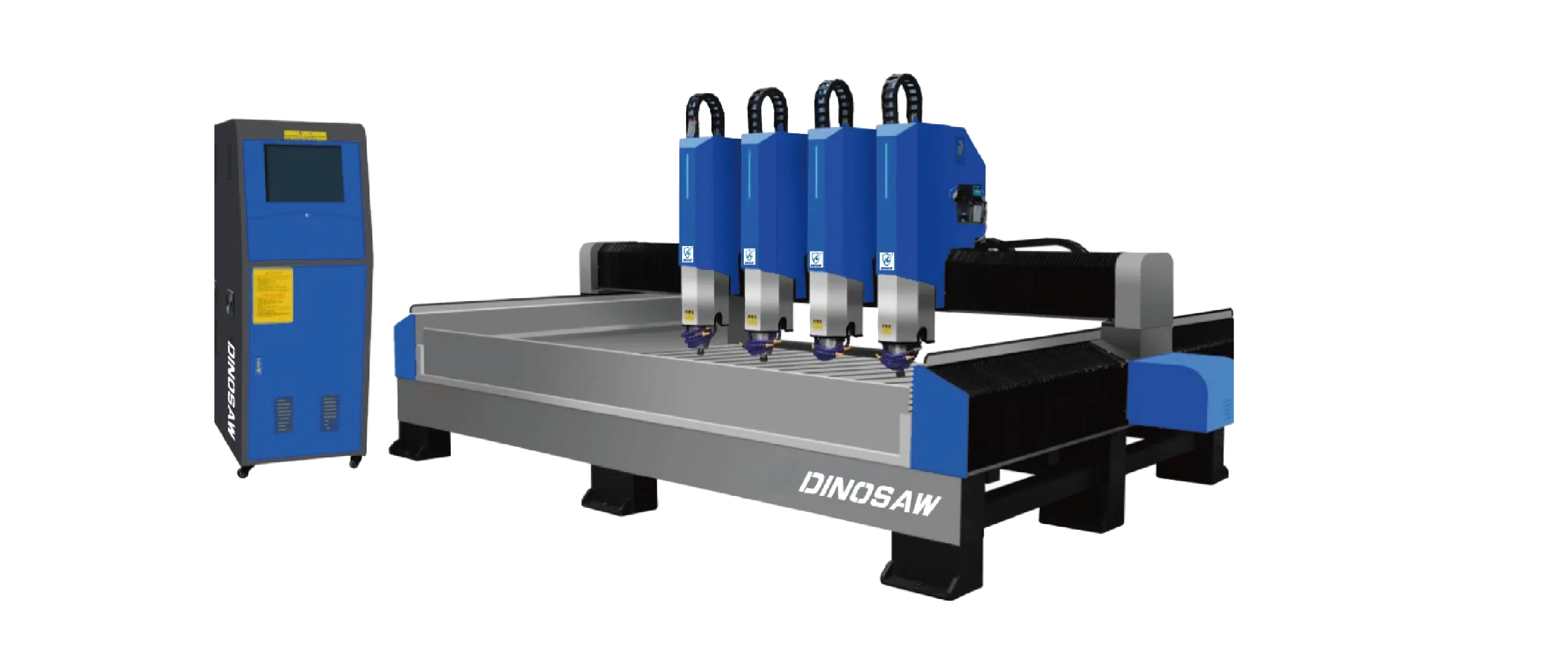

- 5-Axis CNC Router: A highly flexible machine that can produce cylindrical parts, but it mills them rather than turns them. This process is generally much slower than turning on a lathe and may require more complex programming. For a full breakdown of options, see our guide on CNC Stone Cutting Machines: Which Type Works Best.

Procurement Topics for a Stone Lathe for Sale

When evaluating a stone lathe for sale, look beyond the technical specifications. Consider these critical procurement points:

- Spares & Maintenance: What is the availability and cost of critical spare parts? Is there a recommended preventative maintenance schedule and local support?

- Training & Warranty: Comprehensive operator training & warranty are essential for maximizing ROI. Clarify the warranty terms and what level of initial and ongoing training is provided.

- Certifications & Compliance: Ensure the machine meets local safety standards (e.g., CE, UL). Effective dust control is critical for regulatory compliance, as mandated by bodies like NIOSH stone dust controls.

Scenario Recommendations

| Scenario | Recommended |

|---|---|

| Marble Baluster Cutting Machine (Batch) | Horizontal CNC/PLC Lathe |

| Stone Column Machine (Large Ø) | Vertical CNC Lathe |

| Occasional Cylindrical Parts | 5 axis Bridge Saw |

Get a Customized Recommendation

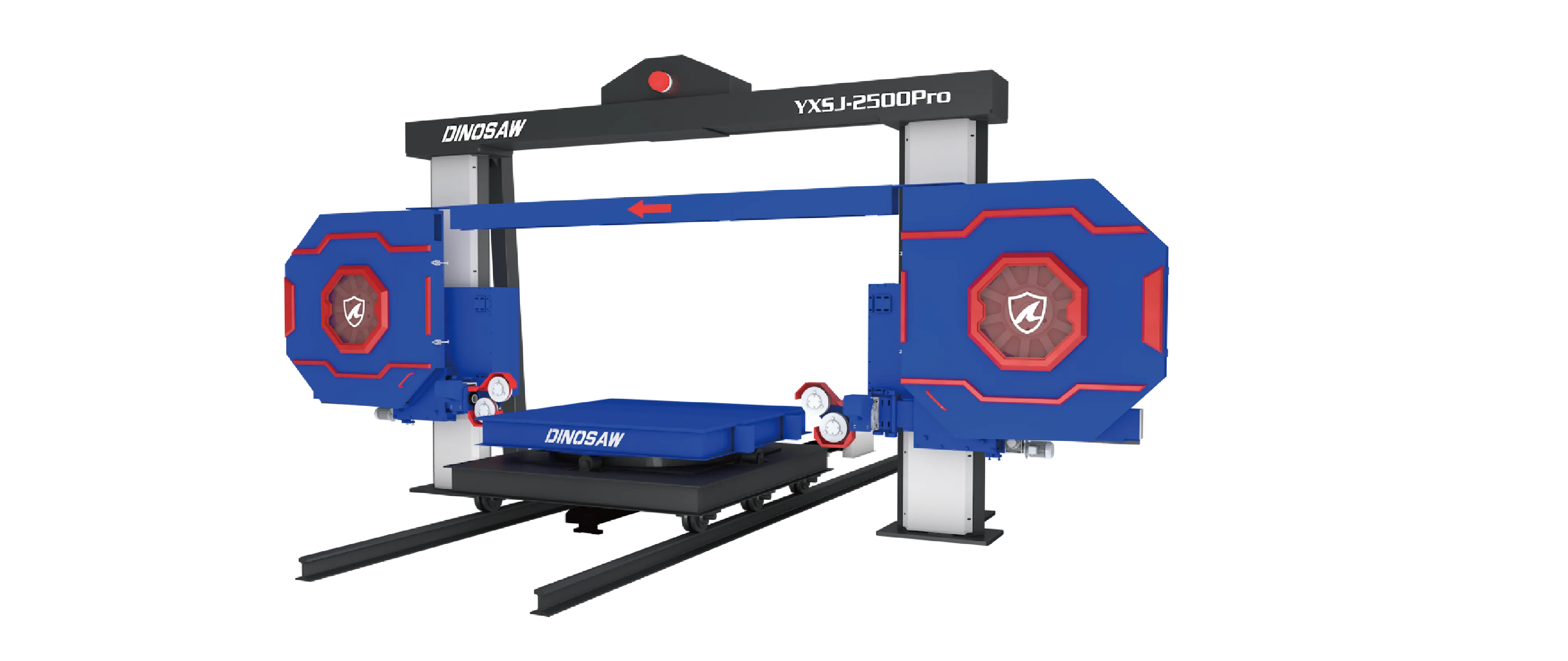

The best machine is one that aligns perfectly with your production goals and budget. Contact our team for a no-obligation consultation. We'll help you compare options and determine if our Bridge-type bidirectional cuts machine is the right investment for you.

Frequently Asked Questions

When to choose a vertical vs horizontal stone lathe (decision checklist)?

Choose based on your primary product's geometry and size.

- Horizontal Lathe: Best for long, slender parts like balusters and columns where support along the length is critical to prevent vibration.

- Vertical Lathe: Ideal for heavy, large-diameter but shorter parts (e.g., column bases) where gravity aids in stable clamping.

- Facility Consideration: Check your factory's footprint and ceiling height, as vertical lathes require more vertical clearance.

Is a stone turning machine better than a bridge saw for baluster profiling?

Yes, a dedicated stone turning machine is far superior for producing cylindrical parts.

- Precision & Roundness: A lathe provides significantly better precision and roundness than a bridge saw with a turning attachment.

- Cycle Time: A lathe is much faster for turning operations compared to milling a cylindrical shape on another machine type.

- Use Case: Only use a bridge saw for occasional, non-critical turning tasks.

PLC vs CNC stone lathe - TCO differences?

A PLC has a lower initial and maintenance cost, while a CNC offers higher flexibility and ROI for mixed jobs.

- Choose PLC: If you produce standardized batches with no variation, a PLC offers a lower Total Cost of Ownership (TCO).

- Choose CNC: If you do custom work, a CNC's flexibility provides a higher ROI despite the larger initial investment.

- Hidden Costs: Factor in training and changeover time, which also impact the long-term TCO.

Which configuration fits granite column turning vs marble baluster cutting?

Match the machine's rigidity and control system to the material and application.

- For Granite Columns: You need a heavy-duty horizontal CNC lathe with a high-torque spindle to handle the hard material.

- For Marble Balusters: A standard horizontal lathe with a profiling wheel is sufficient. Choose CNC for custom designs or PLC for standard batches.

What training & warranty to expect for a stone lathe for sale?

A typical package includes a one-year parts/labor warranty plus on-site commissioning and training.

- Optional: Inquire about extended support packages and local spare parts availability.

- Before Purchase: Always clarify the Service Level Agreement (SLA) for support response times.

Certifications & dust control compliance (NIOSH/OSHA)?

Ensure the machine meets CE/UL standards and that your facility uses wet cutting and PPE to comply with local silica dust rules.

- Reference: For guidance, refer to sources like the NIOSH stone dust controls.

- Facility Responsibility: Your facility must have proper drainage and filtration systems and monitor worker exposure to remain compliant.

English

English