Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Open Hours:8:30am-20:30pm

WhatsApp: +86 198-5901-3937

Open Hours:

8:30am-20:30pm

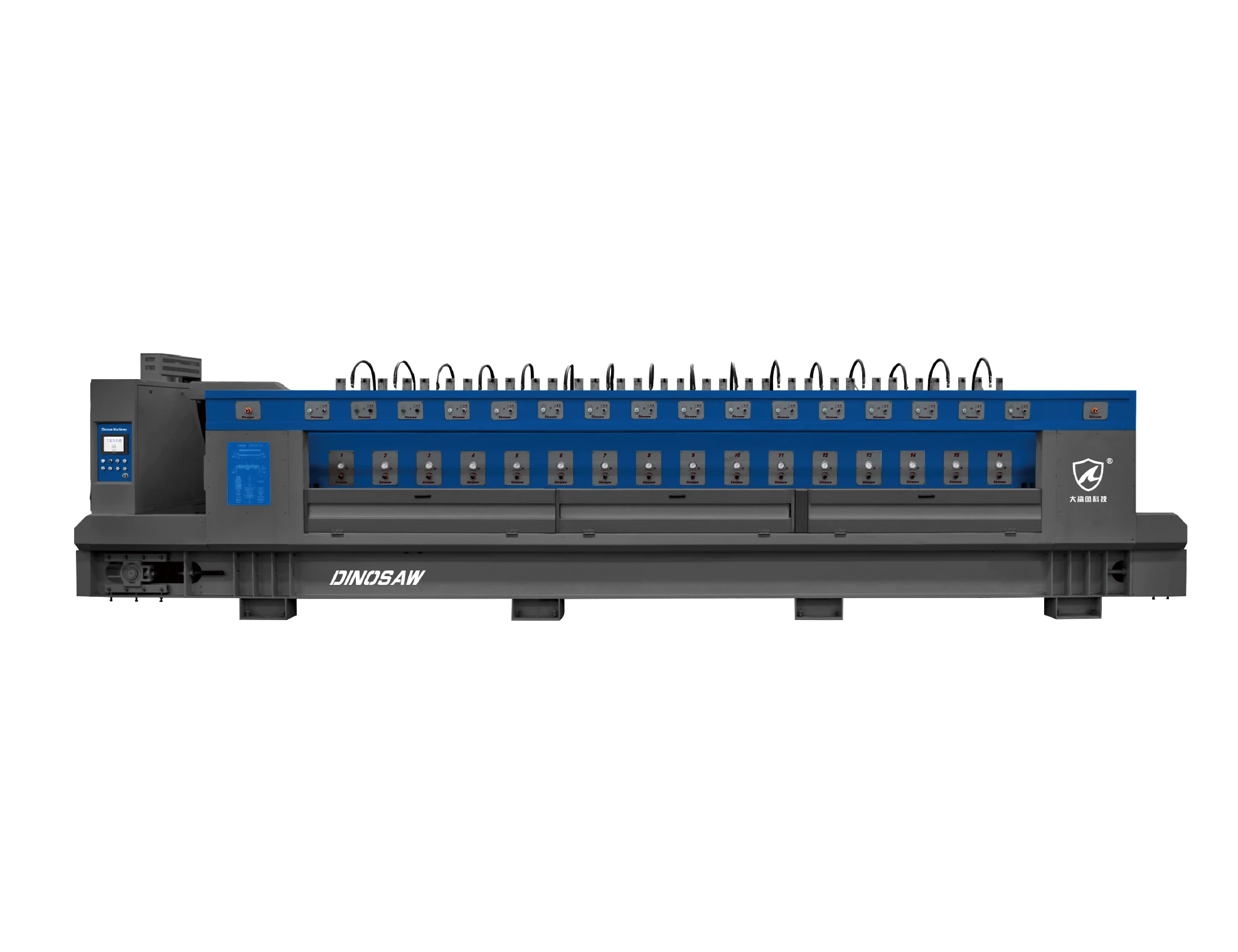

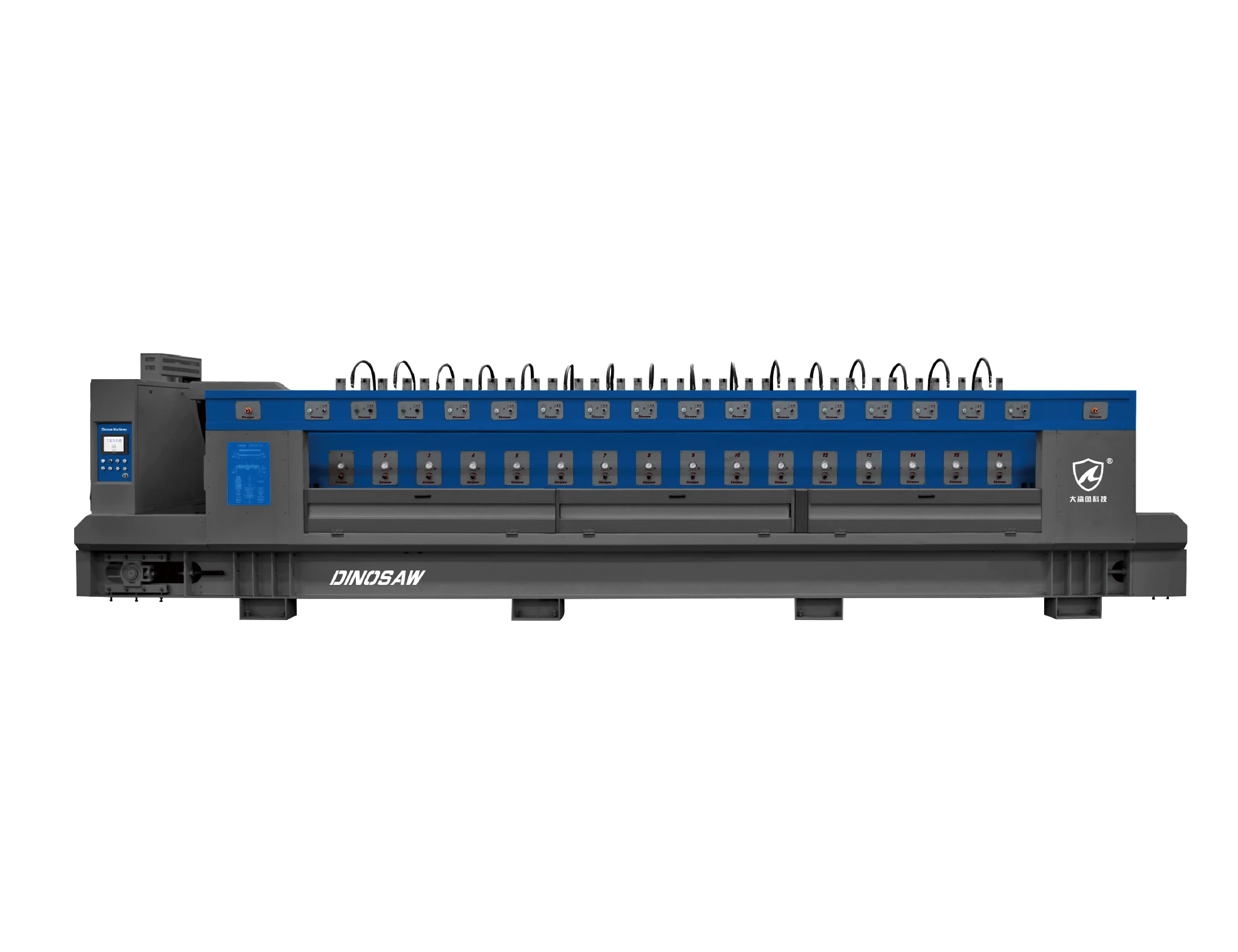

Multi-head Automatic Marble & Granite Polishing Machine

TBMJ-1200/DBMJ-2000

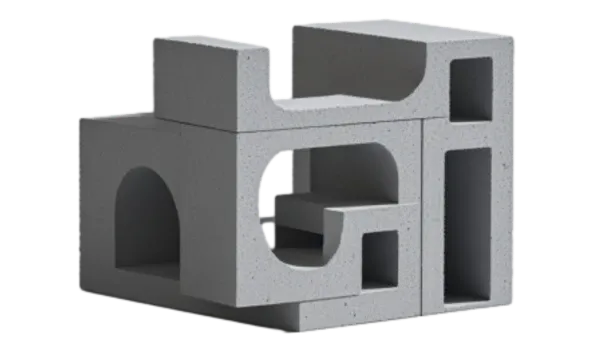

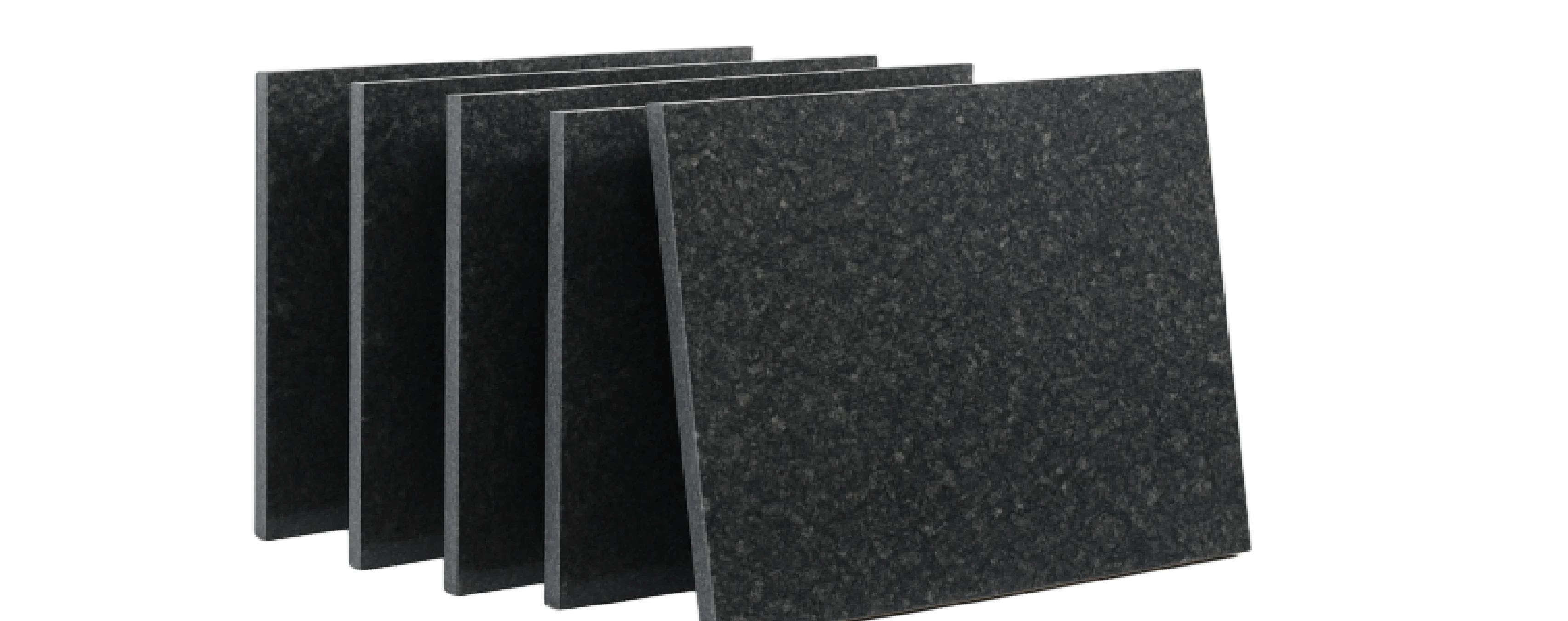

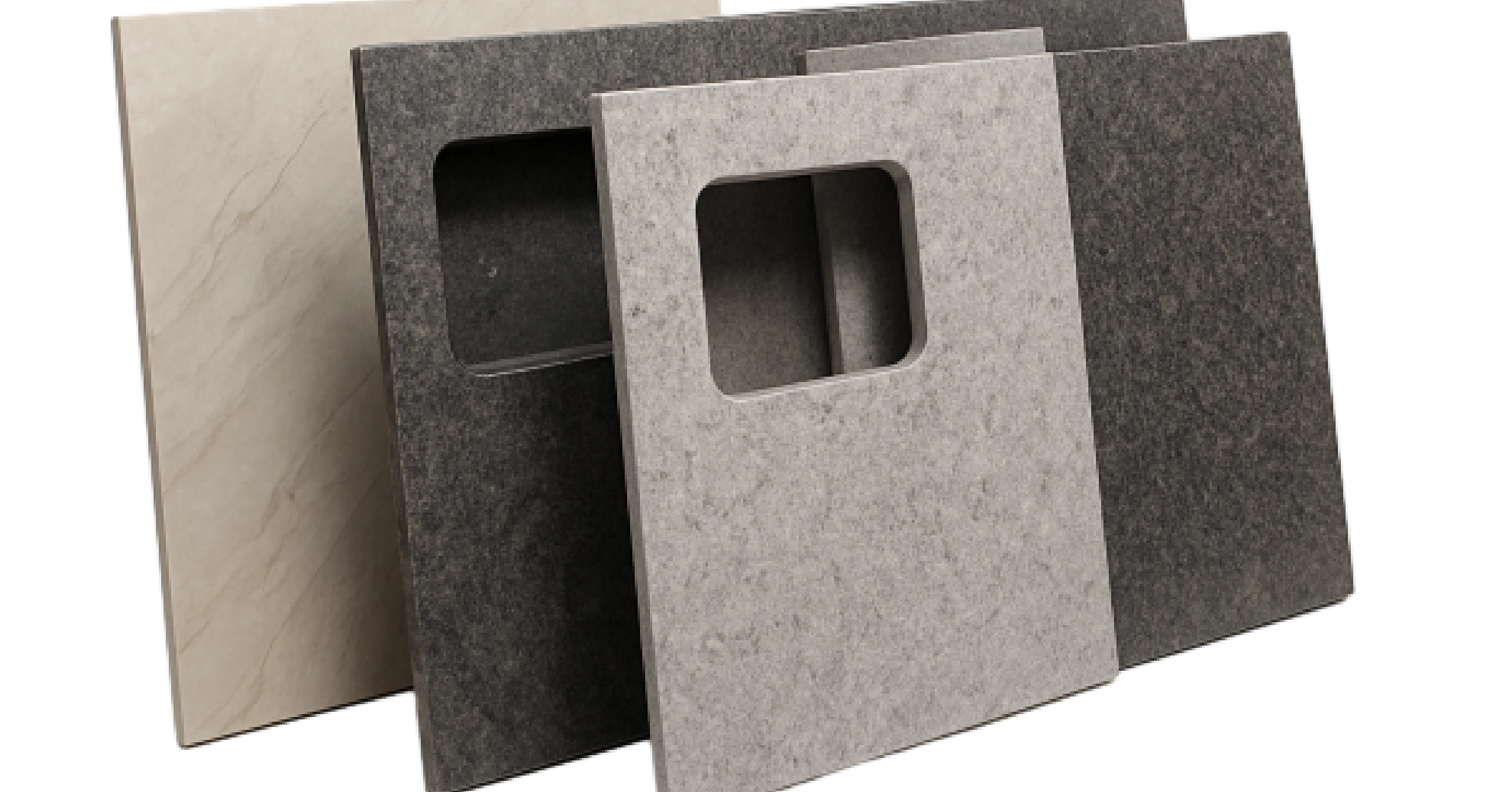

Compatible Materials & Products

Perfect Finishes for Granite, Marble, Engineered Stone & Natural Stones

▶ Product Demo

▶

▶

Marble > Feature Walls & Decorative Panels

|

|---|

|

|

Marble feature walls and decorative panels represent luxury and refinement in high-end architectural applications, with their distinctive veining patterns and timeless elegance enhancing spaces from grand hotel lobbies to executive boardrooms.

The DINOSAW polishing system excels in revealing the inherent beauty of marble through its precision-calibrated finishing process. Our system's laser profiling technology automatically maps the marble slab's dimensions and adjusts the polishing parameters accordingly, ensuring consistent results even with marble's natural variations. The machine's PLC control system maintains exact speed and pressure calibrations throughout the finishing sequence, progressing from initial calibration to final polish while preserving the intricate veining characteristics that make each marble panel unique.

For fabricators specializing in architectural marble applications, our polishing system delivers the perfect balance of production efficiency and artisanal quality, reducing processing time while maintaining the flawless finish that luxury projects demand.

Granite > Countertops & Flooring

Granite countertops and commercial flooring remain the gold standard for durability and aesthetic appeal in high-traffic environments, with growing demand in global markets for their exceptional resilience and striking visual characteristics.

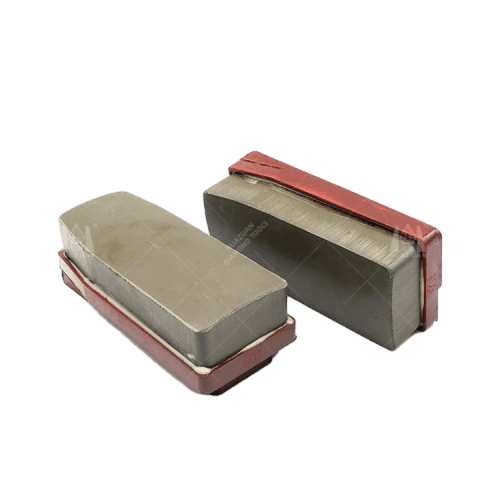

The DINOSAW Multi-Head Polishing Machine transforms raw granite slabs into perfectly finished surfaces with mirror-like polish. Our advanced diamond and resin-bond abrasive system with 8-24 polishing heads progresses through multiple grit sequences, starting with coarse diamonds to remove gang saw marks and continuing to ultra-fine resin-bond pads for that signature high-gloss finish. The independently pneumatic-driven polishing heads maintain precise pressure distribution across the entire surface, eliminating inconsistencies even on large-format slabs.

By implementing our polishing technology, fabrication shops achieve premium-grade finishes with significantly reduced labor costs, substantially increasing daily throughput with just two operators - a productivity level that traditional manual finishing methods simply cannot approach.

Engineered Stone > Premium Surfaces

Engineered stone represents the evolution of premium surfacing materials, combining quartz crystals with polymer resins for enhanced durability and design versatility, making it increasingly specified for luxury commercial and residential applications.

DINOSAW's advanced polishing technology addresses the unique challenges of engineered stone processing. Our machine's precision-controlled polishing heads adapt to the material's composite structure, applying optimal pressure and abrasive progression to achieve the desired surface characteristics. The system's automation and laser mapping capabilities ensure consistent processing across the entire slab, eliminating the variations that often occur with conventional processing methods. From honed finishes to ultra-high gloss, the machine's programmable parameters allow fabricators to achieve precisely the aesthetic specified by designers.

By utilizing our specialized polishing technology for engineered stone, fabrication shops can efficiently produce premium surfaces with exceptional consistency, opening new market opportunities in the luxury surfacing segment while dramatically reducing production costs.

Sandstone & Travertine > Luxury Background Walls

Sandstone and travertine background walls represent timeless elegance in architectural applications, with their natural textures and warm earthen tones creating distinctive spaces in high-end commercial buildings, hotels, and luxury residences.

The DINOSAW polishing system excels in enhancing the natural beauty of these softer, more delicate stone varieties through carefully calibrated processing parameters. Our machine's precision control system automatically adjusts polishing pressure and abrasive progression to accommodate the unique characteristics of these materials, preventing damage while achieving optimal surface quality. The system's laser mapping technology ensures consistent processing across variegated stone surfaces, preserving natural textures while delivering uniform finishes that highlight the stone's inherent beauty.

For architectural stone suppliers, our technology provides the perfect balance of efficiency and artistry, allowing them to process these distinctive materials with confidence while meeting tight project timelines and exacting designer specifications.

Commercial Flooring Projects

65% Higher Output with DINOSAW Multi-Head Polisher

A commercial flooring contractor upgraded to the DINOSAW 24-head polishing system and boosted production by 65%. With just two operators, they now complete large mall installations in half the time while achieving superior finish quality that withstands intensive foot traffic without dulling.

Kitchen & Bath Fabrication

Mirror-Finish Countertops with Labor Savings

A countertop fabricator switched from manual to DINOSAW automated polishing, cutting labor costs by 40%. The system delivers mirror-finish granite and marble surfaces, eliminating manual variations and allowing the shop to handle more high-margin projects with consistent quality.

Architectural Feature Walls

Perfect Pattern Matching Stone Panels

A premier stone supplier used the DINOSAW polishing system to process 5,000m² of polished wall panels for a luxury hotel, finishing two weeks ahead of schedule. The laser profiling ensured perfect alignment of natural veining patterns, creating a seamless appearance throughout the hotel lobby.

Specs and options

Specifications customizable upon request.

| Model | Unit | TBMJ - 1200 - 12G | TBMJ - 1200 - 16G | TBMJ - 1200 - 18G | TBMJ - 1200 - 24G |

|---|---|---|---|---|---|

| No.of heads | n° | 12 | 16 | 20 | 24 |

| Useful working width | mm | 400 - 1000/1300 | 400 - 1000/1300 | 400 - 1000/1300 | 400 - 1000/1300 |

| Useful working thickness | mm | 15 - 50 | 15 - 50 | 15 - 50 | 15 - 50 |

| Belt advancement speed | mm/min | 0 - 3000 | 0 - 3500 | 0 - 3500 | 0 - 3800 |

| Spindle motor power | kw | 7.5 | 7.5 | 7.5 | 7.5 |

| Total power | kw | 96 | 126 | 156 | 186 |

| Water consumption | m³/h | 17 | 20 | 23 | 25 |

| Overall dimensions(LxWxH) | mm | 7500x2150x2200 | 8500x2150x2200 | 9500x2150x2200 | 11500x2150x2200 |

| Weight | t | 15 | 17 | 19 | 21 |

| Model | Unit | DBMJ - 2000 - 12G/M | DBMJ - 2000 - 16G/M | DBMJ - 2000 - 18G/M | DBMJ - 2000 - 20G/M |

|---|---|---|---|---|---|

| No.of heads | N° | 12 | 16 | 18 | 20 |

| Useful working width | mm | 600 - 2100 | 600 - 2100 | 600 - 2100 | 600 - 2100 |

| Useful working thickness | mm | 15 - 50 | 15 - 50 | 15 - 50 | 15 - 50 |

| Belt advancement speed | mm/min | 0 - 3500 | 0 - 3500 | 0 - 3500 | 0 - 3500 |

| Spindle motor power | kw | 9/11/15 | 9/11/15 | 9/11/15 | 9/11/15 |

| Total power | kw | 137 | 181 | 203 | 225 |

| Water consumption | m³/h | 22 | 25 | 26 | 28 |

| Overall dimensions(LxWxH) | mm | 9600x3200x2300 | 11600x3200x2300 | 12600x3200x2300 | 13600x3200x2300 |

| Weight | t | 24 | 27 | 28 | 29 |

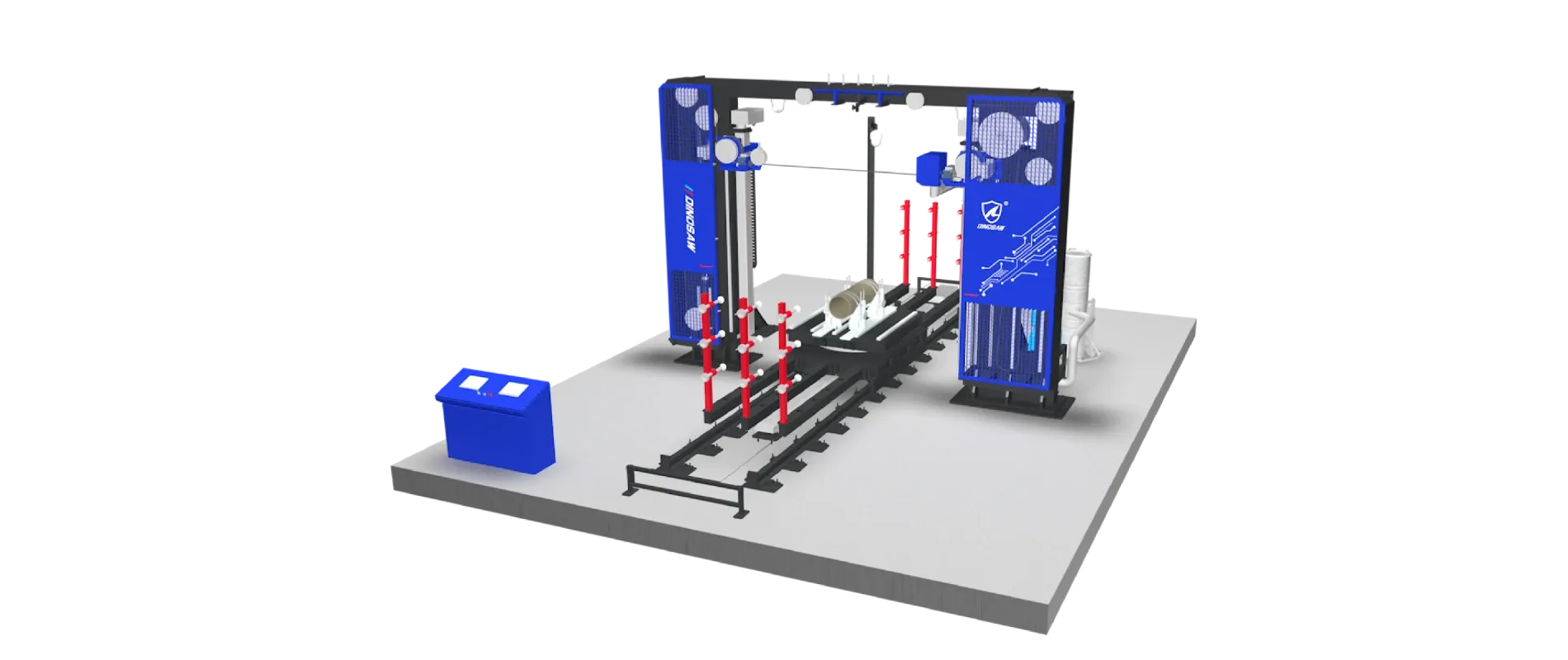

| Standard Equipment Configuration |

|---|

| Main Polishing Unit |

| Automatic Loading Platform with Tilting System |

| Transition Frame with Air-Drying System |

| Transition Frame |

| Automatic Unloading Platform with Tilting System |

Complete production line setup for efficient stone processing from loading to unloading.

Advanced multi-head technology for superior stone surface results

Mirror-Perfect Stone Finishing Automation

High-Efficiency Multi-Head Polishing

Configurable system with multi-heads delivers exceptional throughput for large-scale production

Mirror-Perfect Surface Finishing

Progressive abrasive sequence creates flawless mirror-like surfaces with exceptional gloss

Fully-Automated Polishing Line

PLC control system with automatic loading, conveying and processing

Extended Lifespan

High-strength welded steel frame with cast iron components and precision-machined work surface

Multi-Material Adaptability

Interchangeable polishing heads and abrasives for granite, marble, tile and other materials

Water Cooling System

Integrated cooling protects stone surfaces from heat damage while extending abrasive life

FAQs

Common Questions About Granite Polishing Machines

How to polish granite after cutting?

The professional polishing process for cut granite involves multiple stages, starting with coarse grinding to remove saw marks, followed by progressive finer abrasive sequences, and finishing with ultra-fine polishing to achieve a mirror finish. For industrial-scale production, a multi-head automatic polishing system is essential.

The most efficient approach uses multi-head polishing machines with 8-24 polishing heads working simultaneously through programmed sequences. This system replaces traditional manual polishing (where operators control a single grinding head) and single-head machines (requiring manual abrasive changes between stages). The PLC-controlled process ensures consistent pressure, speed, and abrasive progression across every slab, delivering uniform quality impossible with manual methods.

Water cooling is critical throughout the process to prevent heat damage and extend abrasive life. For optimal results, polishing should progress through 6-8 abrasive stages from 50-grit through 3000-grit. The automated system handles this progression seamlessly, allowing fabricators to process marble, granite and engineered stone with minimal labor while meeting tight project deadlines.

What materials can a stone polishing machine process?

DINOSAW polishing machines are versatile systems capable of processing a wide range of dimension stone and similar materials, including Granite, Marble, Engineered stone, Porcelain slabs, Tiles, Terrazzo and other Natural stones.

The Stone Polisher parameters (pressure, RPM, abrasive progression) can be calibrated through the PLC control system to optimize processing for each specific material type. Different abrasive sequences are recommended depending on the material's hardness and desired finish level.翻译:

How many operators does a stone polishing line require?

One of the key advantages of the DINOSAW stone polishing system is its minimal labor requirement. A complete polishing line typically requires only 2 operators:

• One operator manages the loading zone, ensuring proper slab placement and initial quality control

• One operator oversees the machine operation through the PLC interface and handles final inspection

The automated system handles the entire polishing sequence without operator intervention, allowing staff to manage multiple aspects of production simultaneously.

What's the typical production capacity of stone polishing equipment?

The DINOSAW stone polishing system delivers exceptional productivity with substantial daily throughput in standard 8-hour operation. Actual production capacity depends on several factors:

• Polishing head configuration (more heads generally increase throughput)

• Material type (harder materials typically require longer processing cycles)

• Finish requirements (higher gloss levels require additional processing stages)

• Slab dimensions and thickness

• Production line configuration (automated material handling increases efficiency)

Many fabrication shops operating with optimized configurations and extended shifts achieve significantly higher outputs. The system's reliability allows for continuous operation with minimal downtime, maximizing production capacity and return on investment.

Certifications & Standards

Mirror-Perfect Stone Finishing Automation

CE Certification

100+ Tech Patents

ISO 9001:2015

DINOSAW product lines fully comply with international engineering standards, passing rigorous third-party quality certifications to ensure exceptional performance and durability for all industrial equipment operating in high-load environments.

Expertise & Applications

75+

Countries Served Worldwide

20+

Industry machinery expertise

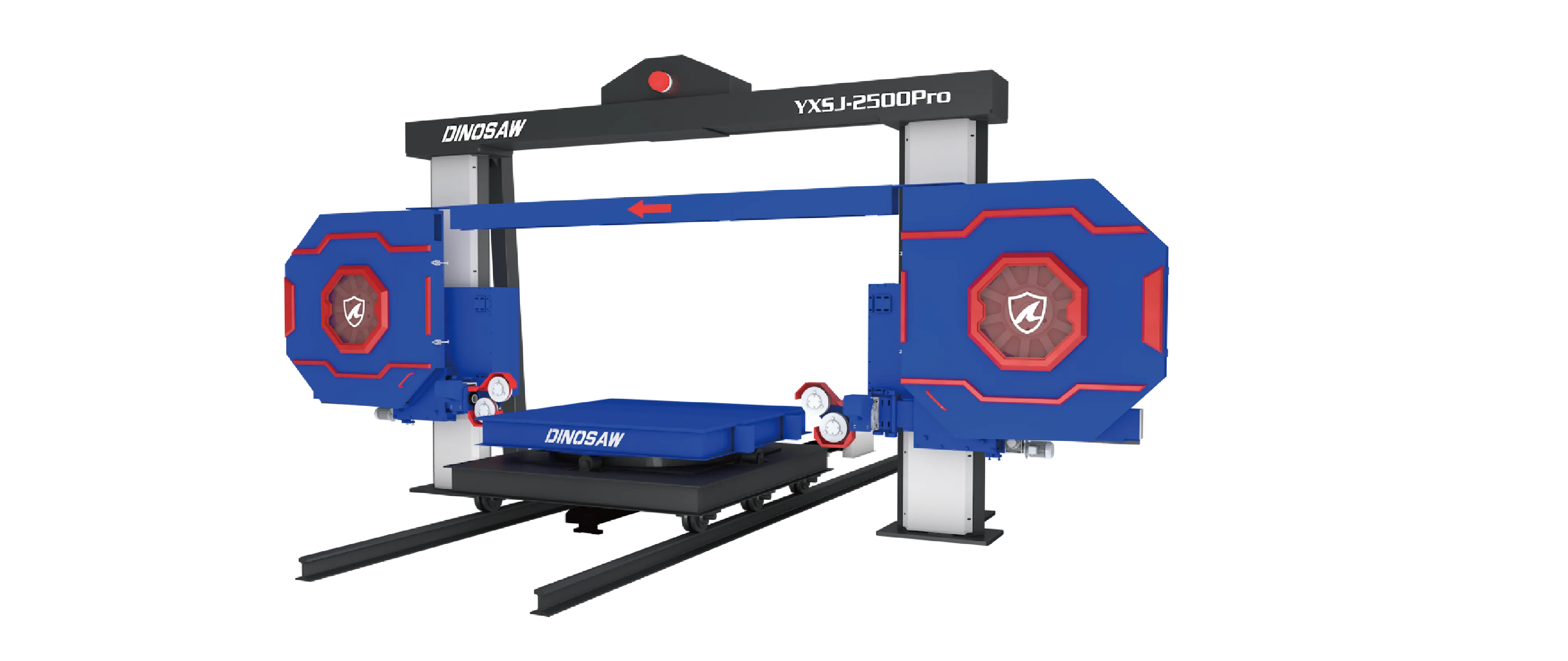

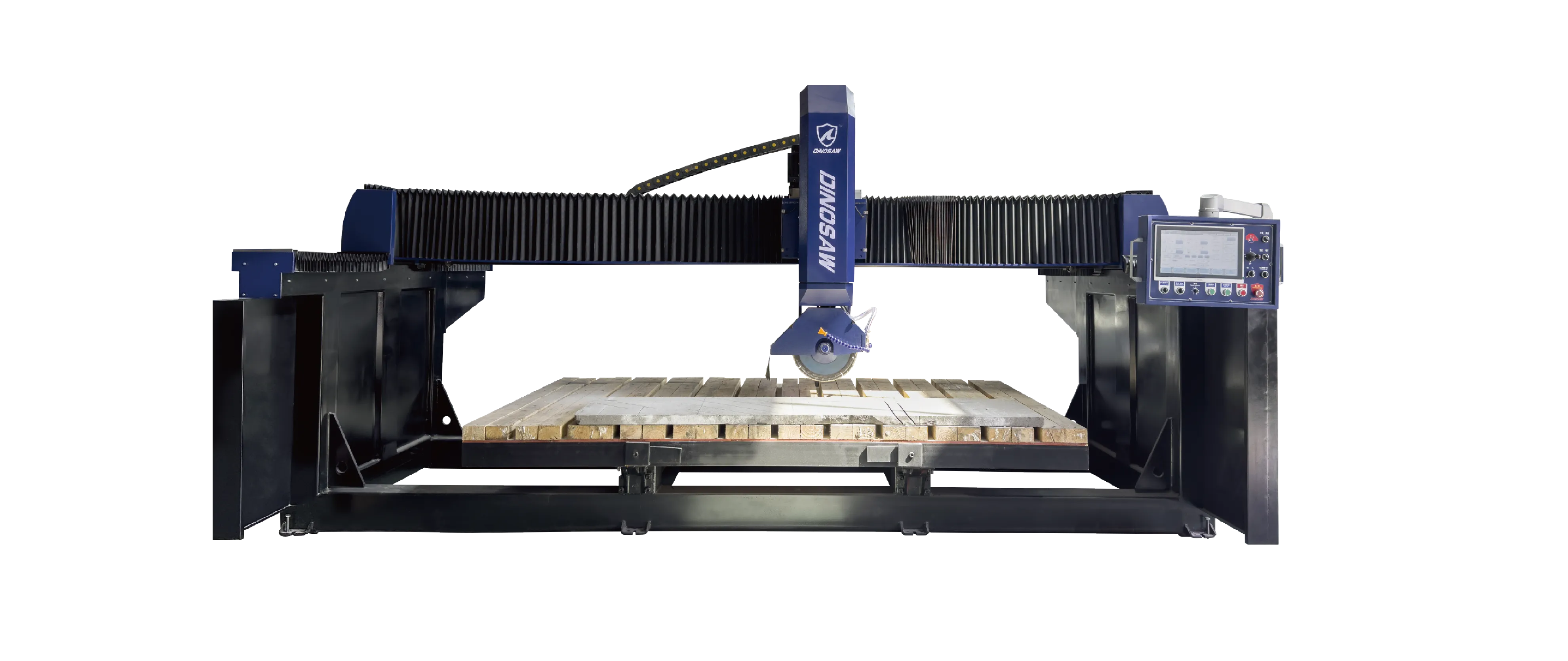

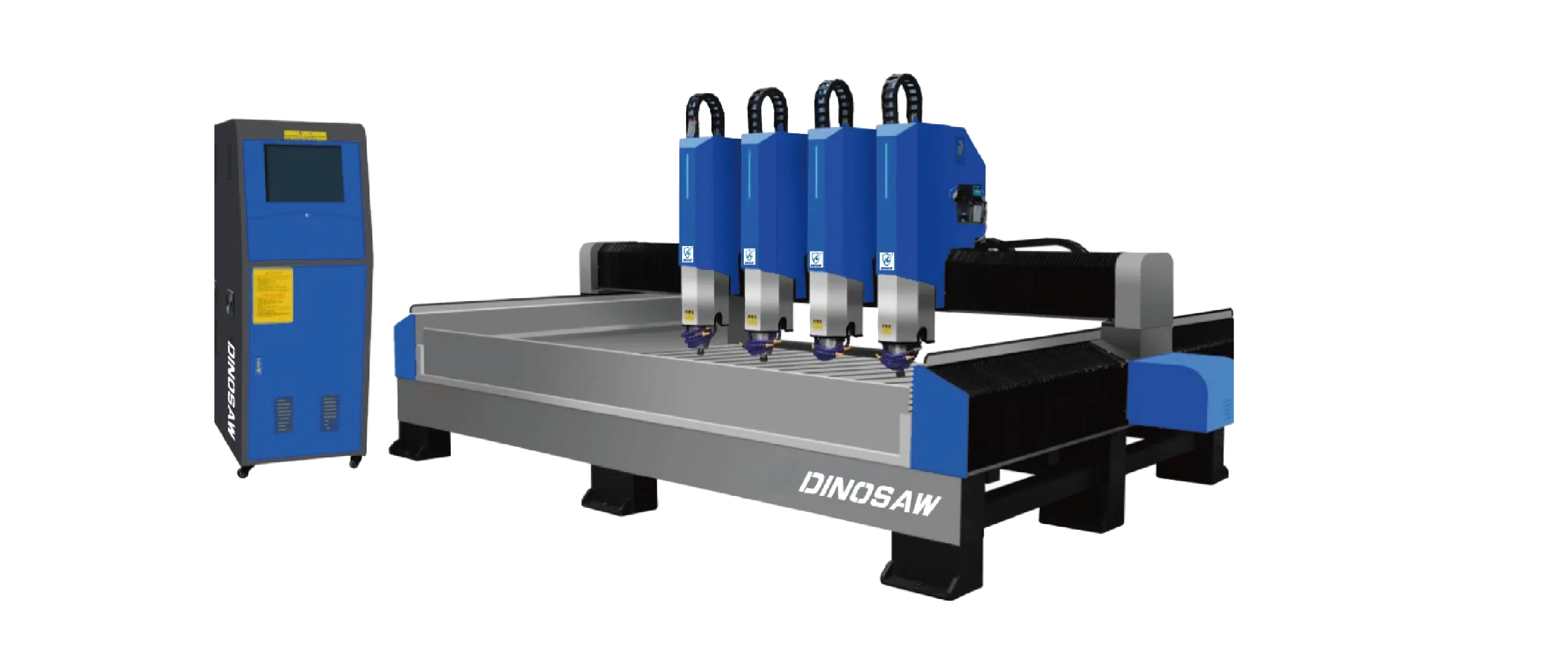

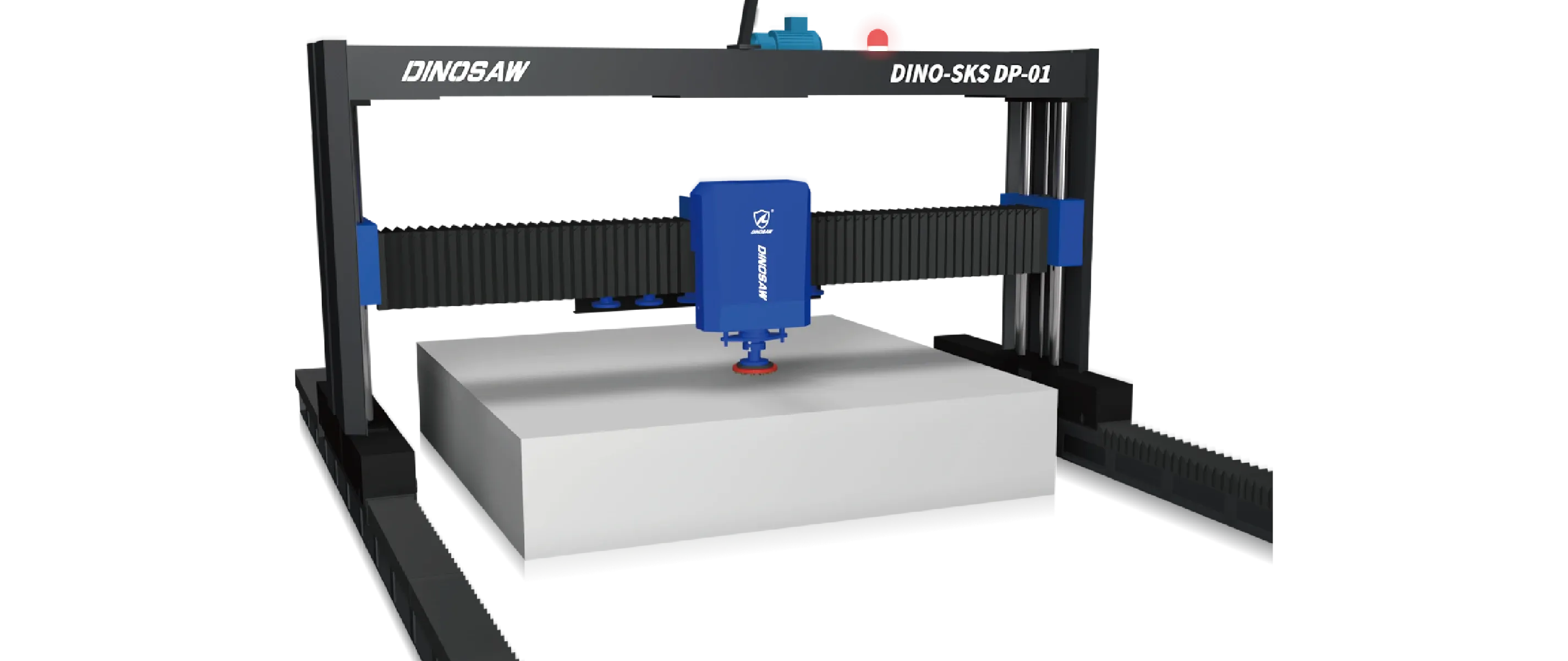

Complete Production Solutions & Equipments

Choose equipment combinations for your product needs to establish efficient automated production lines and maximize profitability.

Ready to Elevate Your Stone Fabrication Capabilities?

Contact DINOSAW for a customized quote on our stone polishing systems and achieve premium finishes

Contact DINOSAW

Connect with DINOSAW experts to find the perfect processing solution for your specific material and production needs.

DINOSAW: Trustworthy Stone Polishing Machine Manufacturer

Discover how DINOSAW can accelerate your projects. Our tailored product line, cutting-edge R&D, robust manufacturing, end-to-end service, global support, and industry certifications are at your service.

Other Machines or Tools

Are you looking for more new information machines or tools?

English

EnglishHello 👋 How can we help?