Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Run stable polishing with SOPs, Top10 fixes, PPE, dust/slurry guidance, and maintenance schedules for diamond pads used on granite, marble, and concrete.

Operational discipline drives finish consistency and significantly lowers rework. Implementing clear Standard Operating Procedures (SOPs), enabling quick troubleshooting, and enforcing proper safety practices are what turn diamond polishing pads into a predictable, high-performance process for finishing granite, marble, concrete, and engineered stone.

This guide provides the essential framework for maintenance teams and operators to run a stable, safe, and efficient polishing workflow. To get the full documentation for your specific pads, request our O&M checklist and troubleshooting quick cards.

Diamond Polishing Pads Standard Operating Procedures

A consistent process starts with a documented SOP. The following checklist covers key steps from start-up to shutdown.

- Start-up: Inspect the tool, backing plate (hook-and-loop), and pad integrity. Confirm the pad diameter (e.g., 4 in/100mm) and ensure a secure mount. For wet mode, check the coolant supply, drainage, and slurry containment. For dry mode, verify the shop-vac or local exhaust setup is functional. Select the correct joint for the task: a flexible single-layer rubber joint for edges and corners, a stable double-layer rubber joint for flats, or an aluminum joint for general-purpose rigid mounting.

- Changeover: Stop the tool completely before releasing the pad. Wipe the backing plate clean, mount the next grit, and tug-test for a secure engagement. Log the grit change, RPM, pressure, and coolant status. Ensure passes overlap by 30–50% for uniformity. Before resuming, confirm the joint type suits the task (e.g., flexible for edges, stable for flats).

- Calibration: Periodically validate RPM at the spindle and the contact speed on a scrap piece. Adjust pressure to achieve uniform gloss and check for flatness and proper edge control.

- Consumables Management: Maintain tool bearings per the OEM schedule. Replace worn backing plates immediately. Stock spare pads for all steps of your grit ladder, basing quantities on manufacturer-reported cycle counts and usage data.

- Safety Checks: Always wear appropriate PPE, including eye/hand protection and a respirator when dry polishing. Confirm your process complies with OSHA silica regulations and that a housekeeping plan for slurry and dust is in place.

Top 10 Common Issues and How to Fix your Diamond Pads

Glazing (Pad Shiny; Poor Cut):

- Cause: Excess pressure/heat; dry use without clearing dust.

- Fix: Reduce pressure/RPM, refresh the pad, or switch to wet mode.

- Prevention: Keep coolant flowing, avoid dwelling, and clean between passes.

Burn Marks / Discoloration:

- Cause: Heat buildup on edges or flats.

- Fix: Lower RPM/pressure, add water, and keep the tool in constant motion.

- Prevention: Use wet polishing on heat-sensitive materials and apply lighter pressure.

Pad Loading (Clogged Abrasive):

- Cause: Slurry and dust accumulation.

- Fix: Increase coolant, rinse the pad, or vacuum between steps.

- Prevention: Ensure continuous water feed and effective drainage.

Chatter / Uneven Gloss:

- Cause: Tool instability or inconsistent pressure.

- Fix: Stabilize the tool, overlap passes consistently, and check backing integrity.

- Prevention: Perform periodic tool calibration and backing plate inspections.

Edge Faceting / Over-Cut:

- Cause: Hard pressure at corners; dwelling too long with a coarse grit.

- Fix: Reduce pressure, shorten dwell time, and move to a finer grit.

- Prevention: Use the pad's conformal contact and lighten up on corners.

Delamination (Pad/Backing Peel):

- Cause: Worn hook-and-loop, excessive heat, or pad age.

- Fix: Immediately replace the pad and/or backing plate.

- Prevention: Inspect before each shift; avoid overheating the pad.

Inconsistent Ladder Execution:

- Cause: Skipped grits or rushed passes without full scratch removal.

- Fix: Revert one grit step and complete uniform passes.

- Prevention: Use an SOP with checkboxes and operator training.

Wobble / Vibration:

- Cause: Bent spindle, worn backing plate, or off-center pad mount.

- Fix: Replace/repair the faulty component; remount the pad.

- Prevention: Check tool health and ensure centered mounting with every changeover.

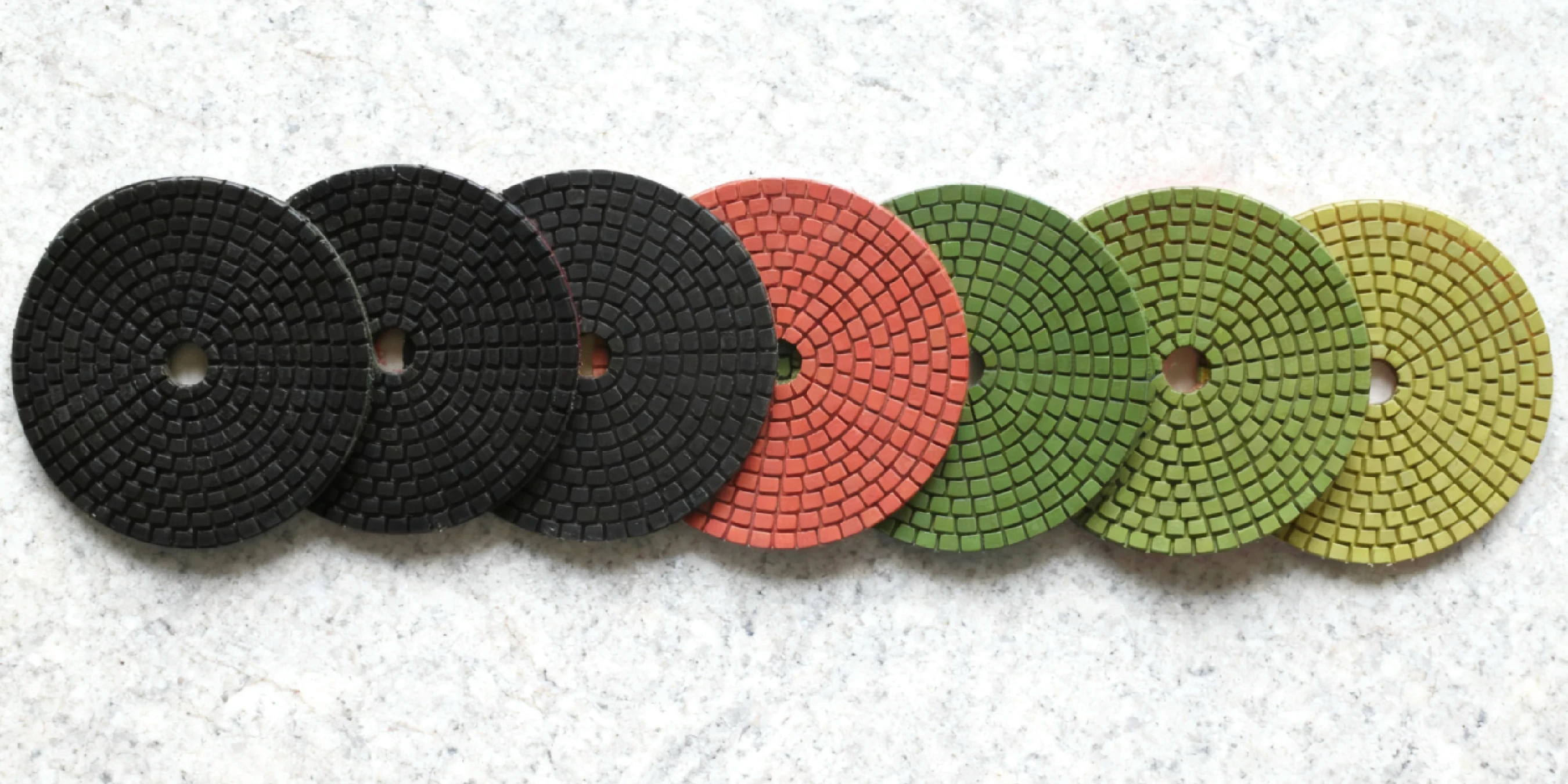

Early Pad Wear / Short Life:

- Cause: Excessive pressure; improper bond type for the material.

- Fix: Adjust pressure; choose resin bonds for finishing and metal bonds for shaping.

- Prevention: Use material-matched pads and provide operator training.

Slurry Streaks / Re-deposition:

- Cause: Poor containment or cleanup.

- Fix: Squeegee and wet-vac the area; rinse and resume.

- Prevention: Implement an edge dam, a drainage plan, and scheduled cleanup.

Pad Retirement Criteria

A pad must be retired when it shows: persistent glazing after being refreshed, delamination of the backing, an uneven cut after cleaning, or visible cracks and excessive wear.

Field Tips from Operators

- Use painter’s tape to create a temporary splash guard. This simple trick can dramatically reduce slurry spread in tight areas, making cleanup much faster.

- To avoid edge burn, feather your passes with lighter pressure and shorter dwell times, especially on corners and sensitive materials.

- Thoroughly rinse pads in clean water when moving up the grit ladder. This prevents coarse diamond particles from carrying over and scratching the finer finish.

Frequently Asked Questions

How do I avoid glazing on my diamond pads?

Reduce pressure and RPM, switch to wet polishing, and clean the pad surface between passes. If glazing persists, the pad may need to be "dressed" or refreshed to expose new abrasive particles.

What PPE is required for dry polishing stone?

At a minimum, eye protection, hand protection, and a respirator rated for silica dust are required. Even with dust collection, a respirator is critical. Wet methods are always preferred to minimize airborne dust.

When exactly should I switch to the next grit?

Switch only after you have completely removed all scratches from the previous grit. Inspect the surface under consistent, low-angle lighting to be certain before moving on.

Can diamond pads be cleaned and reused?

Yes. Rinse them thoroughly in water, gently brush off residue, and allow them to air dry. Do not use solvents. Replace the pad if delamination or persistent glazing occurs.

Should I log RPM and pressure settings?

Absolutely. Logging these parameters improves process repeatability, makes troubleshooting faster, and helps in training new operators. It is a key practice for any quality-focused operation.

How do I manage slurry cleanup effectively?

Use a squeegee and a wet-vac for immediate removal. For larger jobs, plan for edge containment and have a frequent cleanup interval in your SOP to prevent streaks and safety hazards.

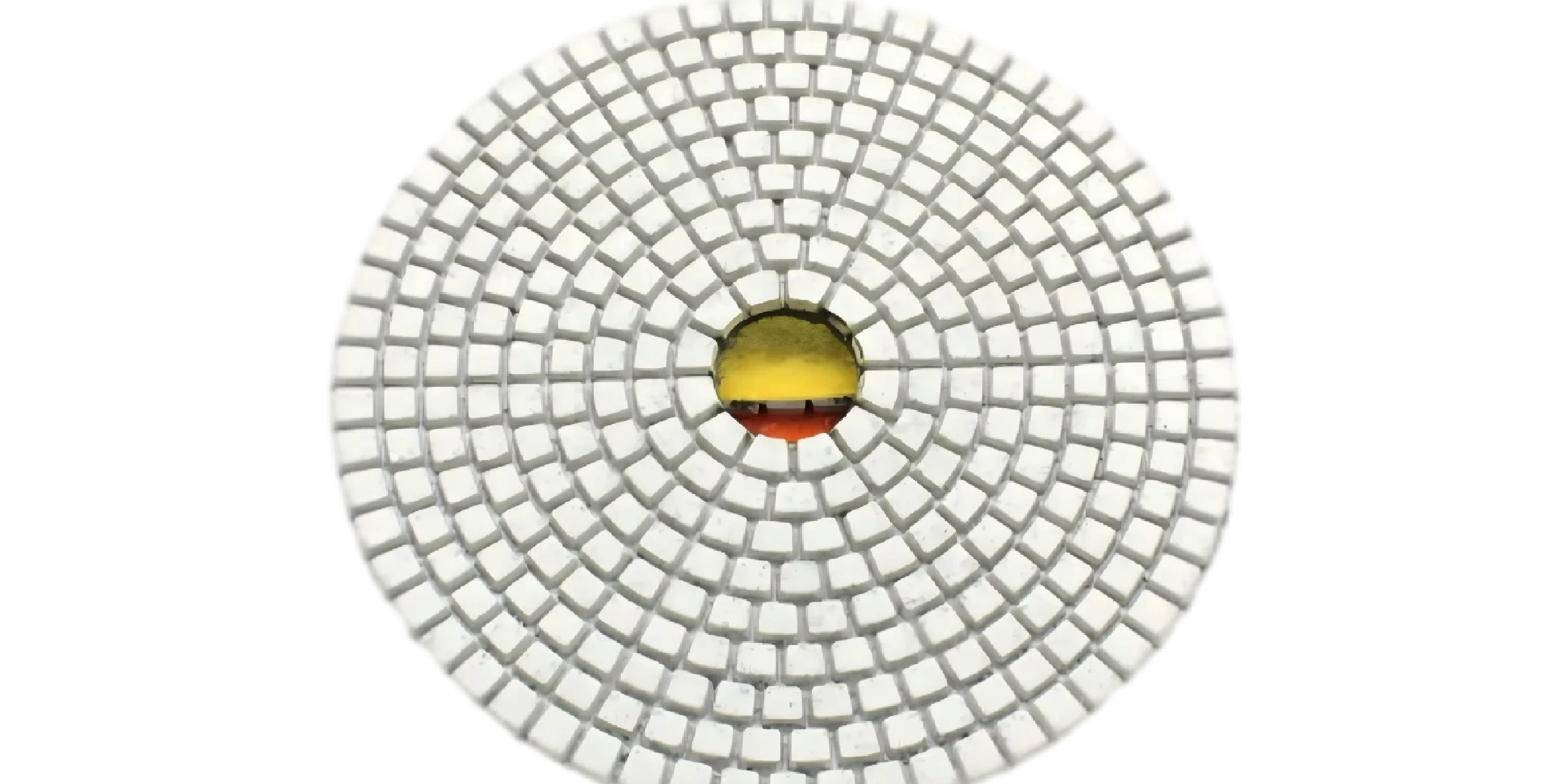

Should I use a black buff or white buff pad?

You should use a black buff pad on black or very dark stones to achieve the final shine. For all other colors, use a white buff pad. Both are finer than 3000# grit and are intended for the final polishing step.

English

English