Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

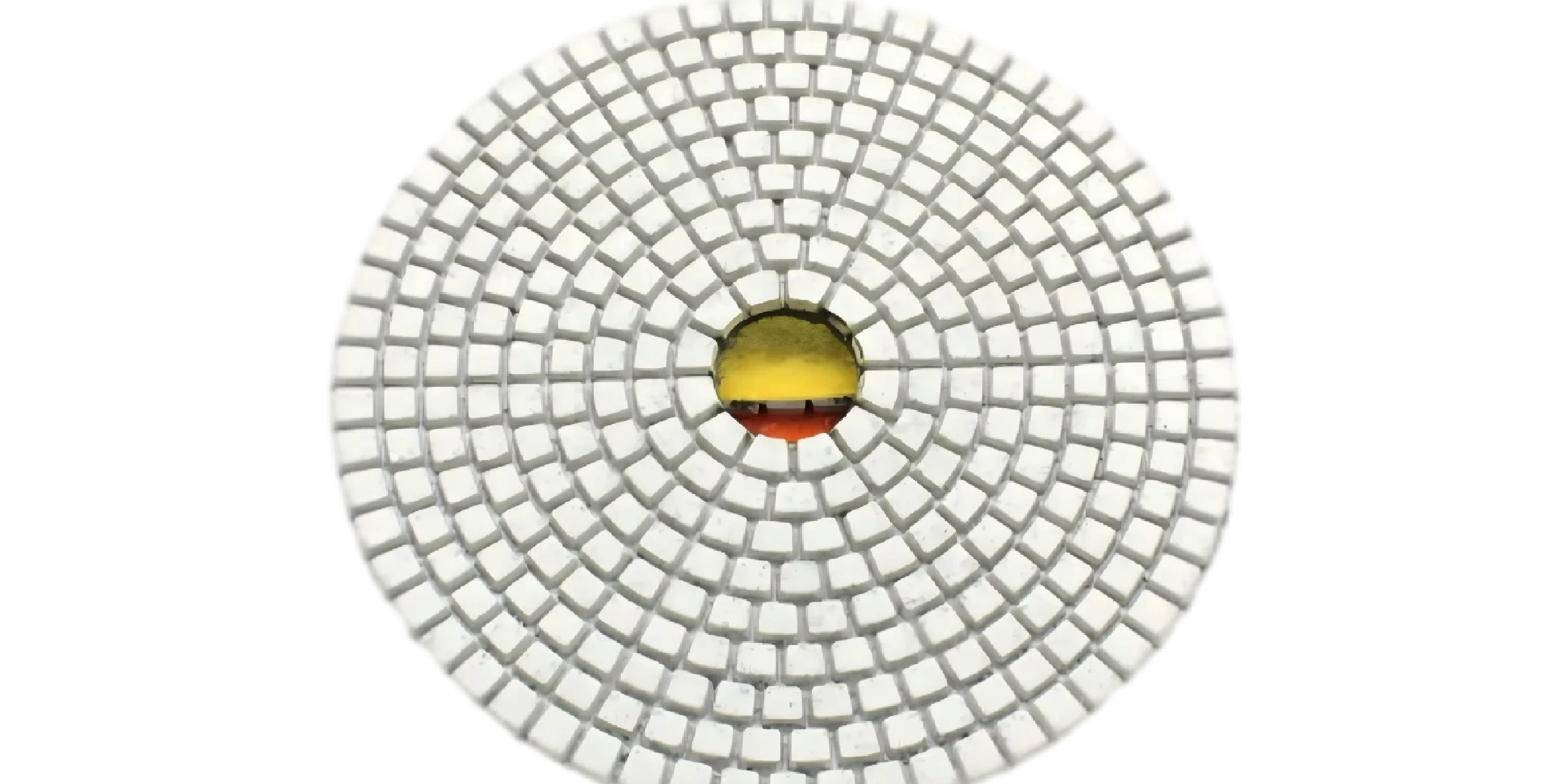

A self-contained guide on why to adopt diamond polishing pads for granite, marble, and concrete, how to implement them using a 4 inch/100mm grit ladder, and what ROI to expect.

Diamond polishing pads are your most direct route to achieving consistent finishes, reducing cycle time, and lowering rework across granite, marble, and concrete. For decision-makers in procurement, operations, and distribution, this guide provides a clear path to predictable outcomes: stable gloss, fewer defects, and safer operations.

If you need to consult, purchase diamond grinding discs or become our agent, Inqury us now.

Why Do You Need This Dimoand Pad & What Is It?

- Why you need it: Compared to generic abrasives, diamond pads reduce the number of required passes, stabilize gloss levels, and cut rework rates. The result is more predictable costs and higher throughput for your shop.

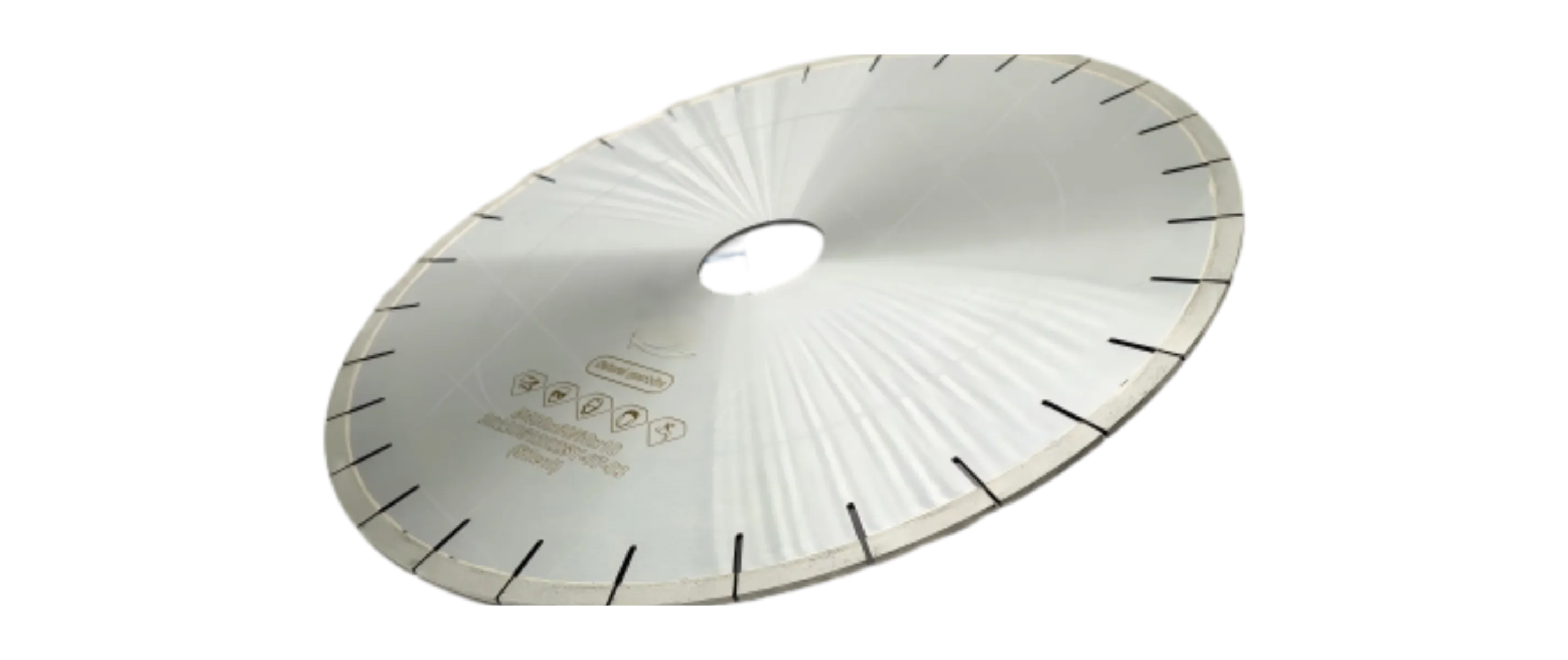

- What it is: A layered consumable featuring industrial diamond particles held in a resin or metal bond. It includes a flexible matrix and a hook-and-loop backing for quick changes, designed to refine hard surfaces through a defined sequence of grit ladders (e.g., #50 to #3000).

How Do You Evaluate & Implement a Diamond Pad Workflow?

A structured evaluation and phased implementation process minimizes risk and ensures a successful rollout.

- Baseline Audit: Document your current finish KPIs (gloss units, defect rate, cycle time).

- Selection & Validation: Choose bond type, grit ladder, and mode based on material; validate on scrap.

- SOP Setup: Define RPM, pressure, and coolant flow per tool specifications; train operators.

- Safety Controls: Ensure compliance with silica exposure limits using wet methods or local exhaust ventilation.

- Pilot & Rollout: Run a limited batch with parameter logging, standardize successful settings, and replicate.

Your Decision Map and Quick-Start Guide

Ready to start? This section provides a simplified decision map and a checklist for getting started. For a detailed walkthrough, refer to our blogs on Applications & Use Cases and our Selection Guide.

Quick-Start Checklist: Are You Ready?

- [✓] Environment: Coolant, drainage, and ventilation ready.

- [✓] Interfaces: 4 in/100mm hook-and-loop backing plate in good condition.

- [✓] Safety: PPE and OSHA compliant dust/slurry controls in place.

- [✓] Parameters: Use material-specific starting points and validate on scrap.

- [✓] Step Plan: Default to the 7-step ladder (50#→3000#); use alternate 4/5-step paths with a BUFF pad for soft, large-grain stones.

Detailed Guides & Resources

This executive guide is supported by a series of in-depth articles.

- Diamond Pads Applications & Cases: A quick overview of where pads excel—flooring, edge profiling, patch finishing—with practical grit ladders and boundaries.

- Diamond Pads Technical Principles: How bonds, grits, RPM, and coolant shape finish and repeatability; mitigation for glazing, burns, and loading.

- Diamond Pads Selection Guide: Dimensions, bond choice, grit ladder, backing, dry/wet—plus If-Then trees and procurement topics.

- Diamond Pads O&M Guide: SOPs, Top 10 fixes, maintenance schedules, field tips, and silica-safe practices.

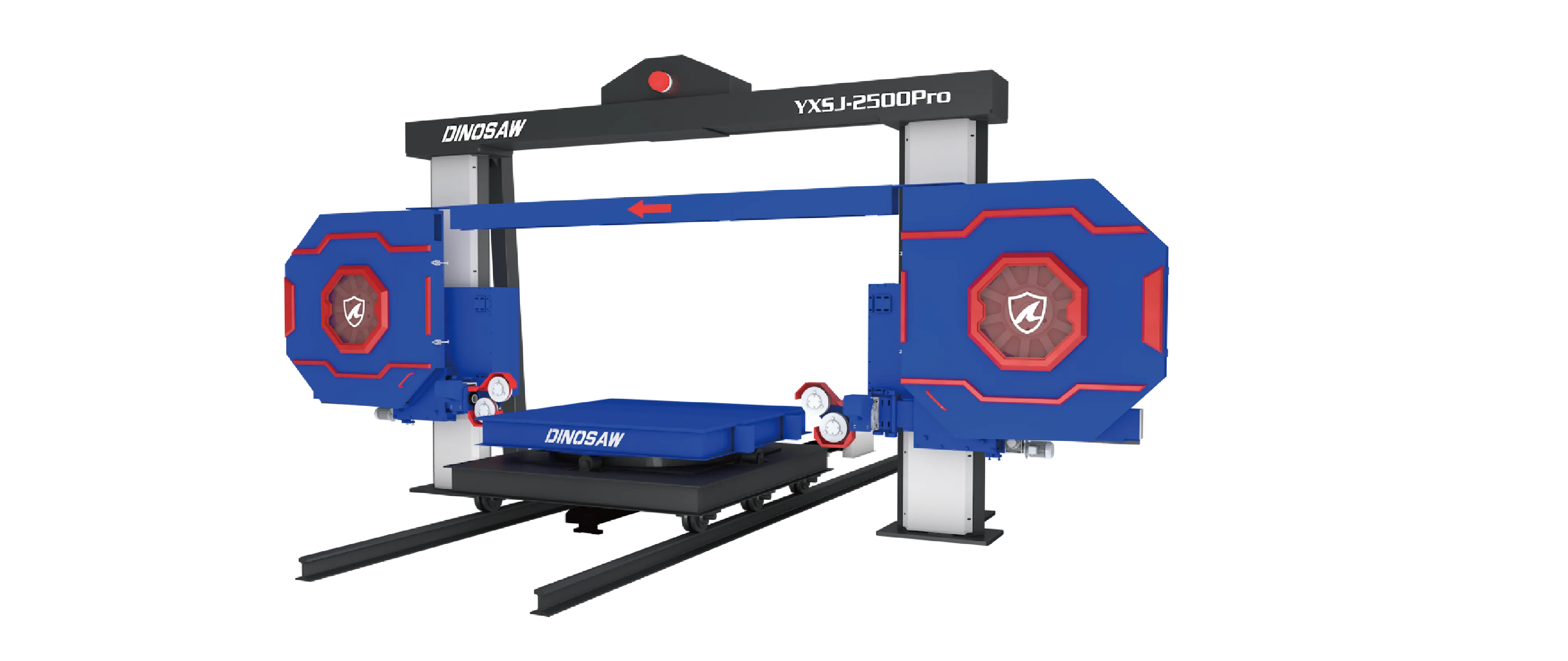

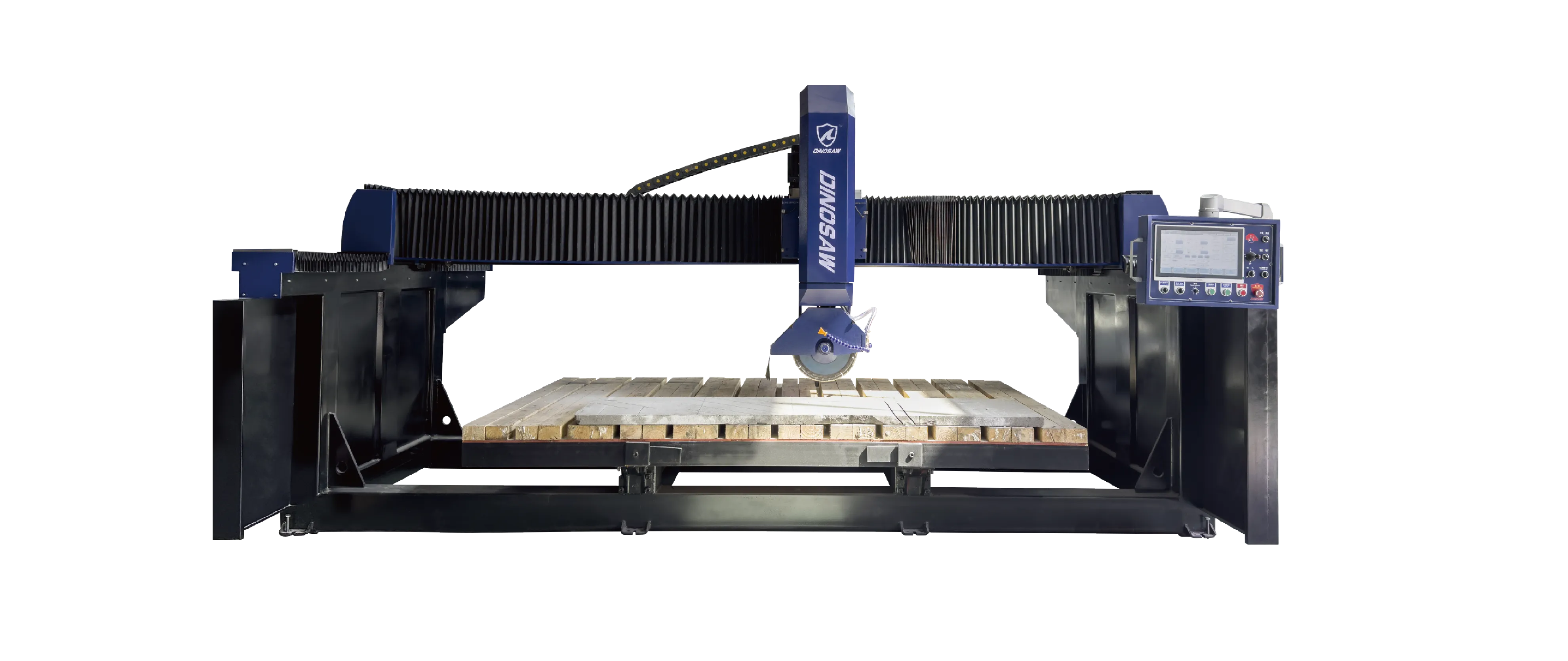

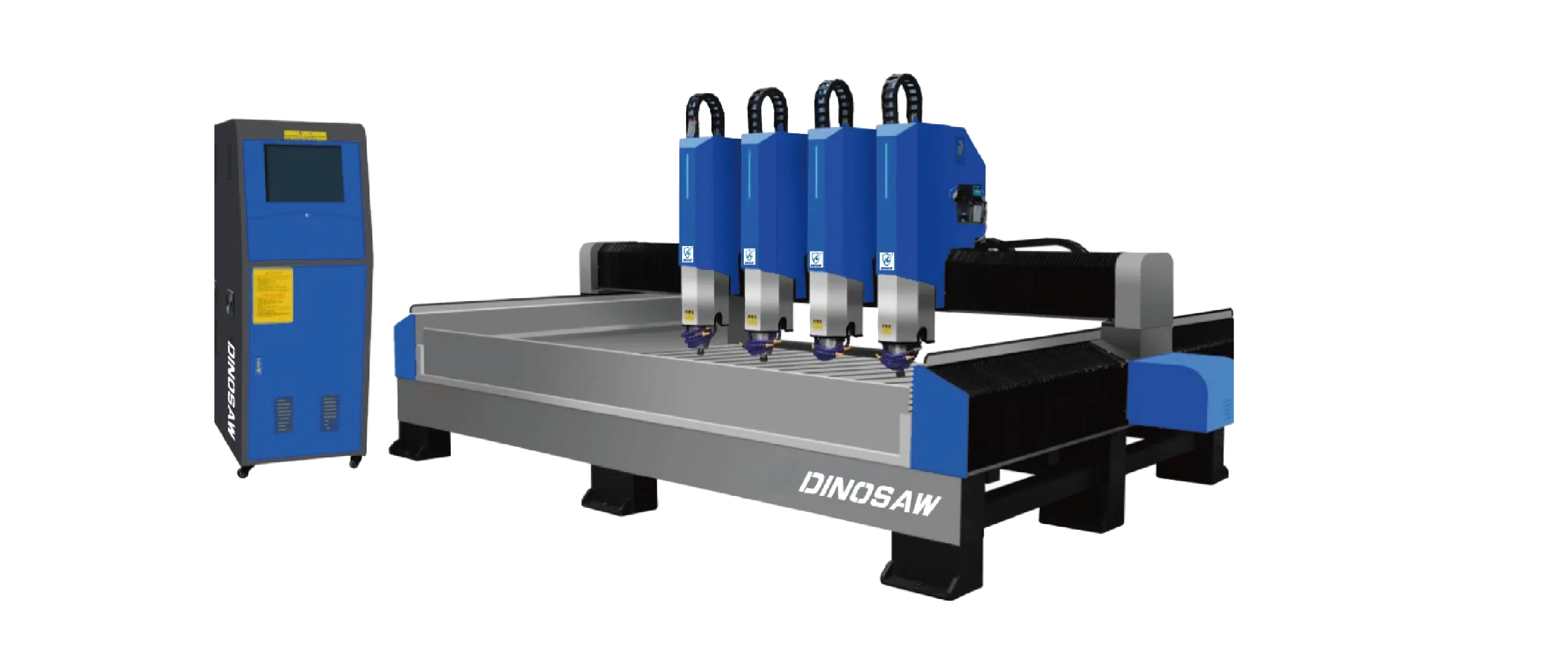

Why Choose DINOSAW as Your Diamond Pads Supplier

We’re built for business buyers — procurement teams, distributors, and agents — with predictable supply, clear documentation, and hands-on technical support.

- Procurement‑friendly terms: tiered pricing, MOQs aligned to project size, quick quotes, and purchase contract support.

- Stock & lead time transparency: standard grits (#50–#3000) and BUFF (black/white) kept in rolling stock; customized ladders on request; clear ETAs.

- Distributor / agent programs: territory enablement, co‑marketing kits, demo pads, and technical training for your sales/service teams.

- Technical support: application audits, starting parameters by material, SOP templates, and troubleshooting playbooks.

- Compliance & safety: documentation aligned to OSHA silica controls and NIOSH dust guidance; MSDS available.

- Logistics: global shipping with consolidated orders; export documentation; warranty and RMA handling you can rely on.

Partner with us: tell us your role (procurement / distributor / agent), monthly volume, target materials (granite, marble, concrete, terrazzo, tile), and preferred grit ladders — we’ll reply with pricing tiers, stock status, and a pilot kit.

Frequently Asked Questions

What makes diamond polishing pads more consistent than generic abrasives?

They give you repeatable results because of their defined grit ladders, controlled bond materials, and standardized RPM/pressure windows. This consistency holds across different materials and operators.

How should I choose between resin and metal bonds?

You should use resin bonds for finishing and achieving a high gloss. For aggressive shaping and material removal, you should use metal bonds.

Can I mix dry and wet polishing in one workflow?

Yes, and it's a common practice. You can start with dry passes for mobility and initial shaping, then switch to wet polishing for the final stages to get the highest gloss and best dust control.

What are the signs of glazing and how do I fix it?

Glazing looks like a shiny, smooth surface on the pad that no longer cuts. To fix it, you can reduce pressure and RPM, refresh the pad, or switch to a wet polishing mode.

What RPM is recommended for 4 in/100mm pads?

You should always use a moderate, stable RPM according to your polisher's manual. Make sure you validate your settings on a scrap piece before starting production to avoid any issues.

Should we track finish KPIs during pilots?

Yes. You should log gloss units (GU), cycle time, rework rates, and pad changes. This data is what you'll use to validate the process and standardize your operations.

Do inner hole sizes matter for pad selection?

Usually not for standard setups. Typical inner holes are 16mm for 100mm pads, 20mm for 125mm pads, and 25mm for 150mm pads. If you have a special holder or non-standard machine thread, you should confirm the size in advance.

English

English