Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover the complete anatomy of a CNC bridge saw. Our 2025 expert guide breaks down every component, from the 5-axis head to the software. Make a smarter investment.

A CNC bridge saw is the workhorse of modern stone fabrication, transforming massive granite, marble, and quartz slabs into precision countertops and architectural elements. Understanding its anatomy is crucial for making smart equipment investments that will define your shop's capabilities for years to come.

What is a CNC Bridge Saw, and What Makes it Essential?

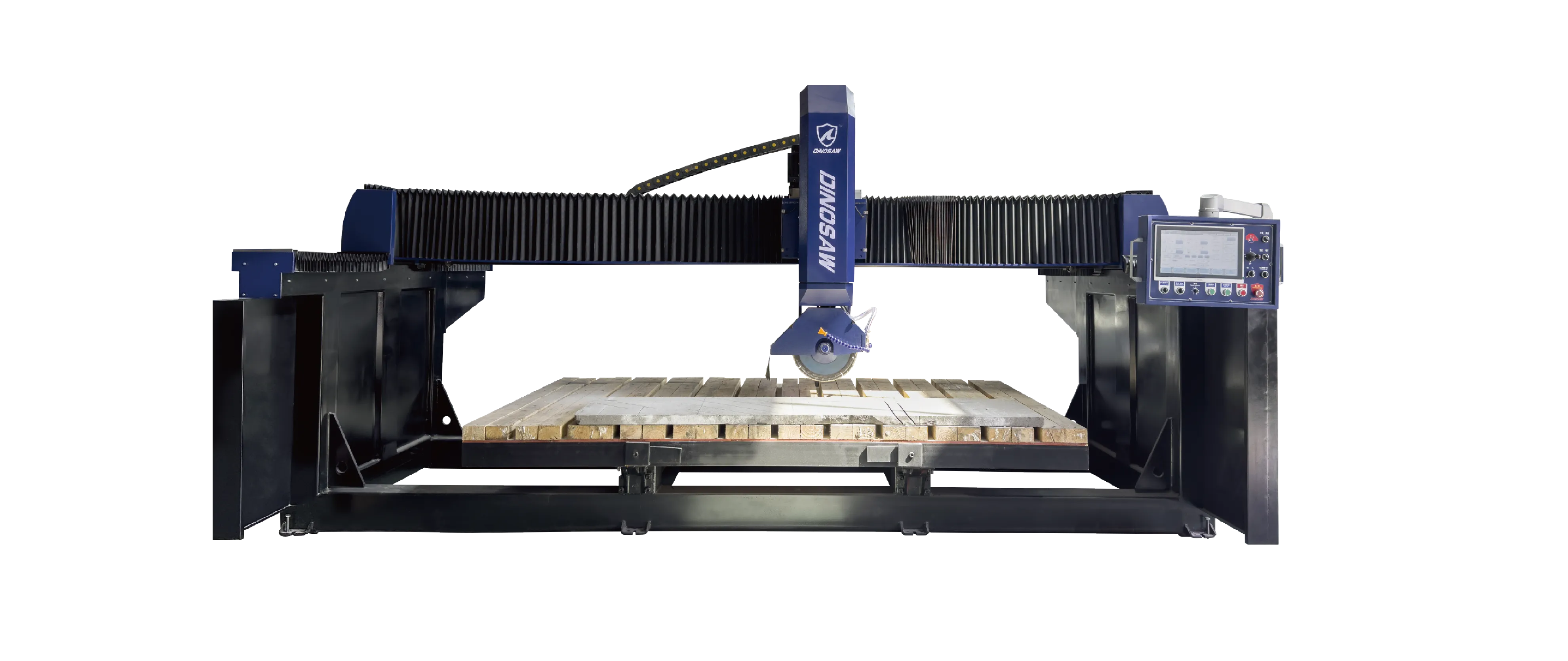

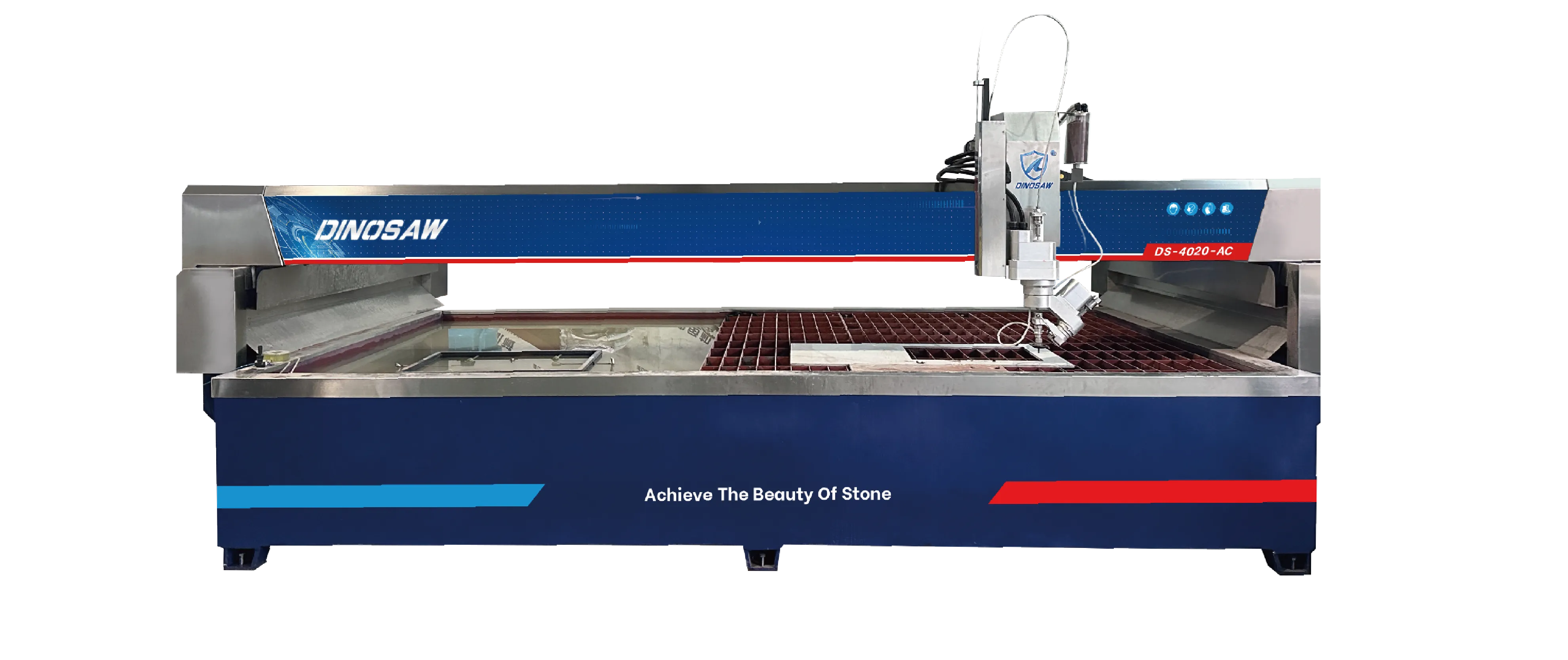

A CNC bridge saw is engineered for one primary purpose: making exceptionally precise straight and angled cuts in large stone slabs. The name comes from the prominent "bridge" or gantry that spans across the worktable, carrying the cutting head. What sets it apart from manual saws is the CNC controller that automates every movement, ensuring each cut achieves digital accuracy-typically within fractions of a millimeter.

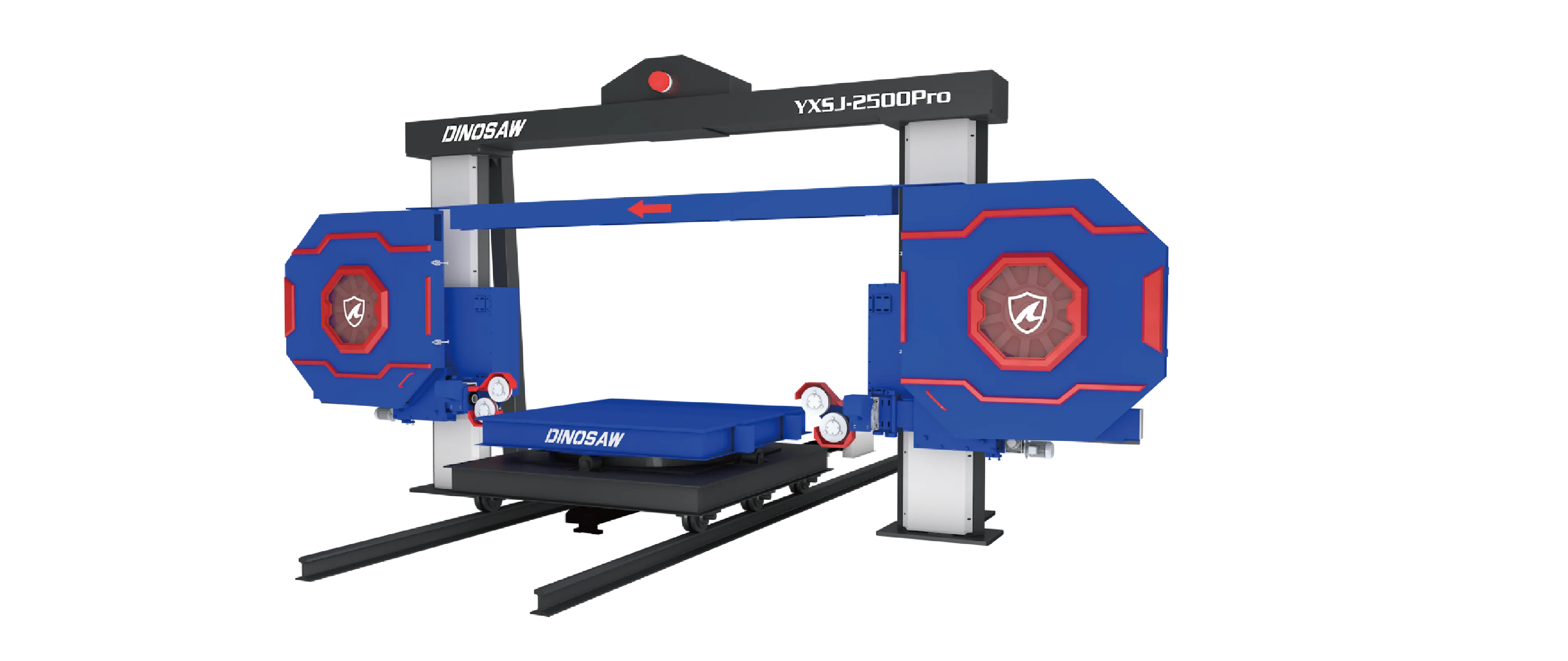

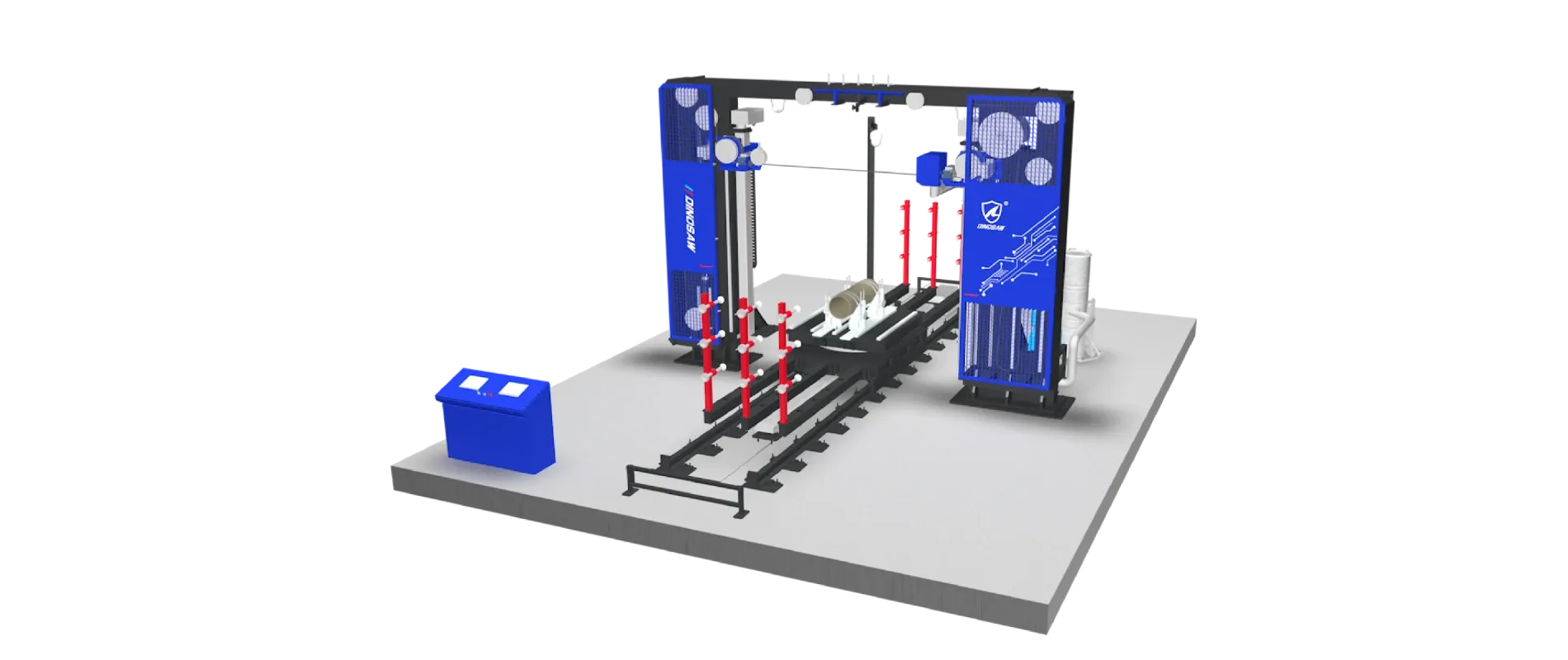

While other technologies serve specific roles-waterjets excel at intricate curves, wire saws handle quarry blocks-the bridge saw dominates slab fabrication. Its combination of raw power, cutting speed, and surgical precision makes it irreplaceable for processing countertops, flooring, and wall cladding materials.

The numbers tell the story. The global stone processing market is projected to exceed $5 billion by 2030 Grand View Research , driven by increasing demand for natural stone applications. This growth underscores why efficient, reliable bridge saws aren't just tools-they're business necessities.

The Foundation & Structure: Where Precision Begins

Here's a truth that catches many buyers off guard: a saw's accuracy depends entirely on its stability. Even minor vibrations during cutting can cause chipping, dimensional inaccuracies, and premature wear on blades and motors. That's why the machine's foundational structure is arguably its most critical-yet frequently overlooked-feature.

Monoblock Frame vs. Concrete Wall Foundation

CNC bridge saws are built on two primary foundational designs:

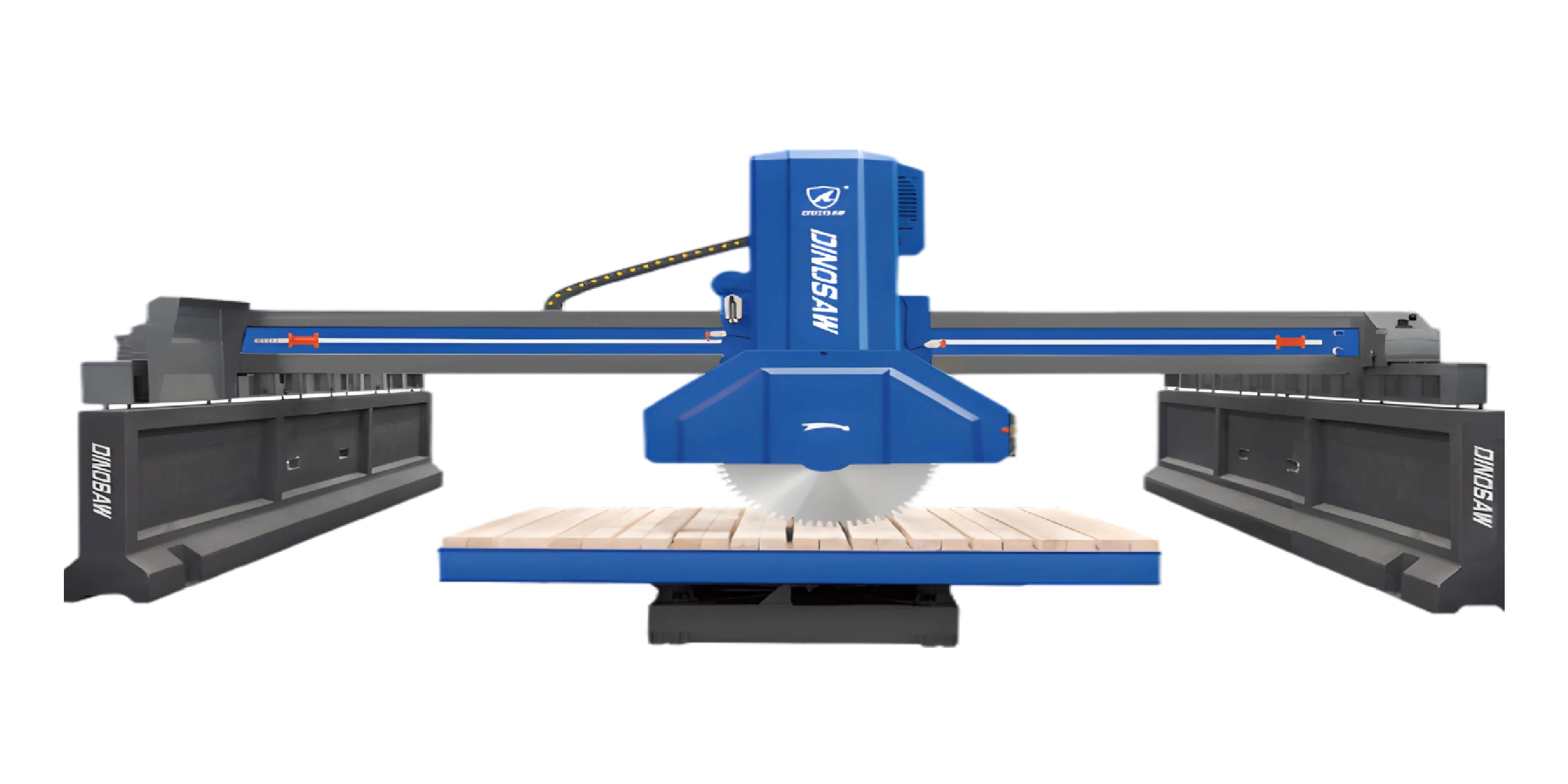

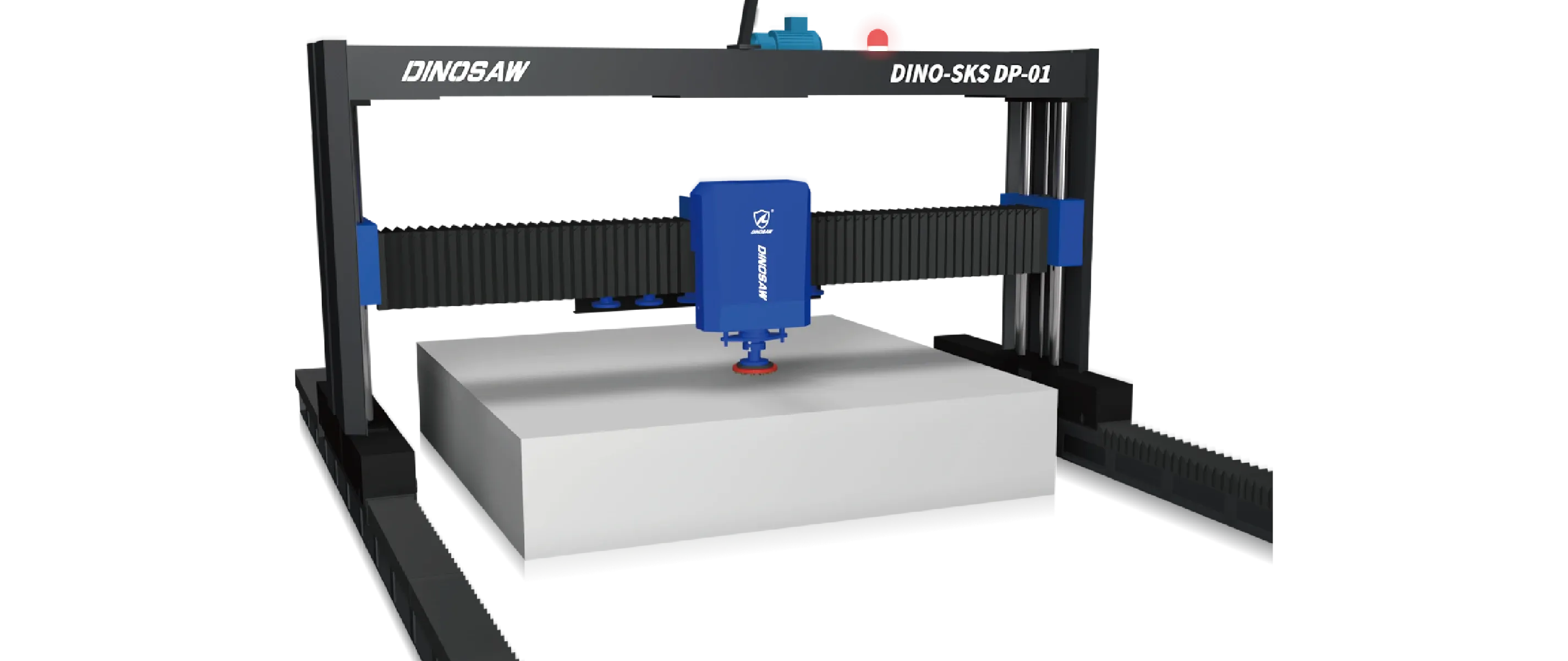

- Monoblock Frame: This design features a single, massively heavy steel base that needs no special foundation. The main advantage? Installation speed and simplicity-most can be operational within a single day. Dinosaw's Monoblock Bridge Saw for countertops delivers exceptional rigidity in a compact package, perfect for workshops where space and setup time are priorities.

- Concrete Wall Foundation: High-volume, industrial operations often choose machines mounted on dedicated concrete walls or pillars. This approach provides maximum stability and vibration damping but requires substantial civil engineering work and permanent installation.

The Bridge (Gantry): The Backbone of Precision

The bridge is the massive beam-typically cast iron or heavy-gauge steel-that spans the worktable. It houses the track system where the cutting head travels (the Y-axis). The bridge's immense weight and robust construction are crucial for absorbing vibrations from the powerful motor and blade cutting through dense stone.

A well-engineered gantry is the hallmark of a durable, high-performance machine. This is why a Heavy-Duty Bridge Saw for Granite Slabs becomes essential for shops regularly handling thick, hard materials.

The Cutting System: Where Power Meets Precision

If the frame provides the skeleton, the cutting system delivers the muscle. This is where raw horsepower translates into clean, precise cuts-defining both the machine's performance ceiling and its daily capabilities.

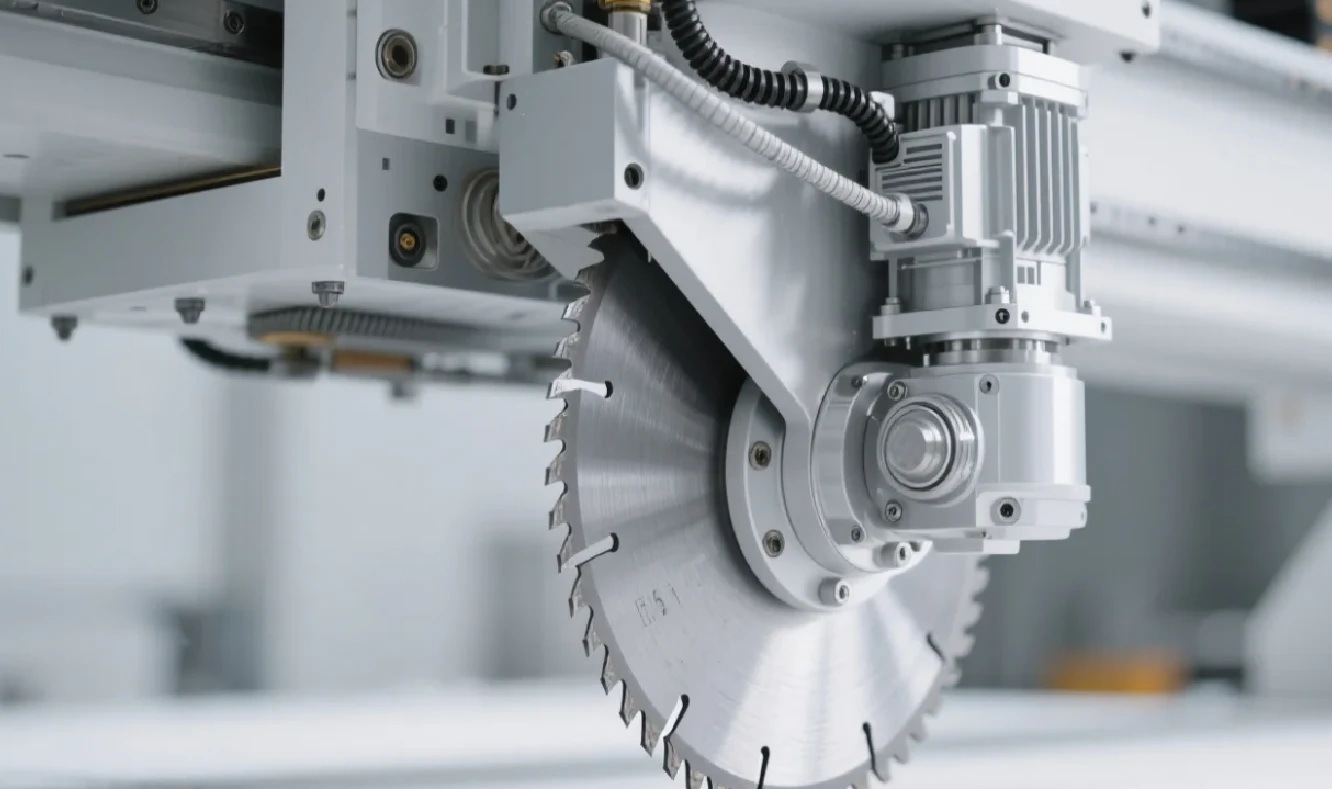

The Blade Head Assembly: The Business End

The saw head is a sophisticated assembly containing the main motor that spins the blade, the arbor that secures it, and the housing that enables tilting and rotation. Motor horsepower (HP) is a key specification, with most machines ranging from 15 to 30 HP. Higher horsepower enables faster cutting speeds and the ability to power through thicker, denser materials without stalling.

The Diamond Blade: Cutting-Edge Technology

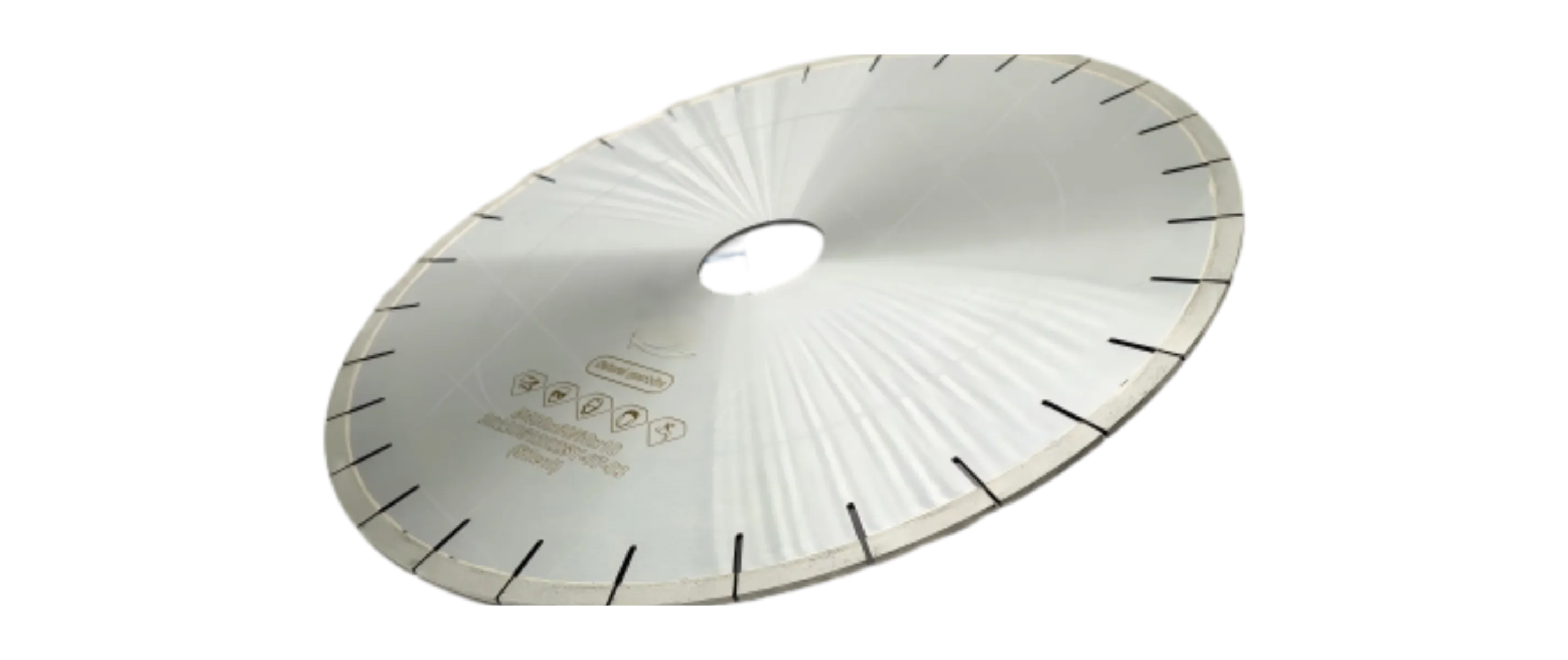

The diamond blade represents remarkable material science advancement. It consists of a solid steel core with diamond-impregnated segments welded around its perimeter. According to the Natural Stone Institute, using proper tooling is essential for sustainable and efficient processing.

Diamond quality and the metallic bond composition determine the blade's cutting speed and lifespan. Matching blade type to material-whether granite, marble, or quartzite-is crucial for achieving chip-free finishes.

The Axis System: Defining Bridge Saw Capabilities

The number of axes a CNC bridge saw has determines its versatility and job complexity capabilities:

- 3-Axis: The standard configuration provides movement in three directions: X (lengthwise along rails), Y (across the bridge), and Z (up and down). The head typically adjusts manually or pneumatically for 0° and 45° miter cuts.

- 4-Axis: Beyond X, Y, and Z movement, a 4-axis machine features a programmable tilting head (A-axis). This enables the blade to tilt to any angle between 0° and 90°, allowing complex miter cuts for waterfall edges and custom joinery.

- 5-Axis: The pinnacle of bridge saw technology, a 5-axis machine adds a rotating head (C-axis) to the tilting capability. This allows 360° blade rotation, enabling curves, circles, and intricate shapes-essentially creating an all-in-one stone machining center.

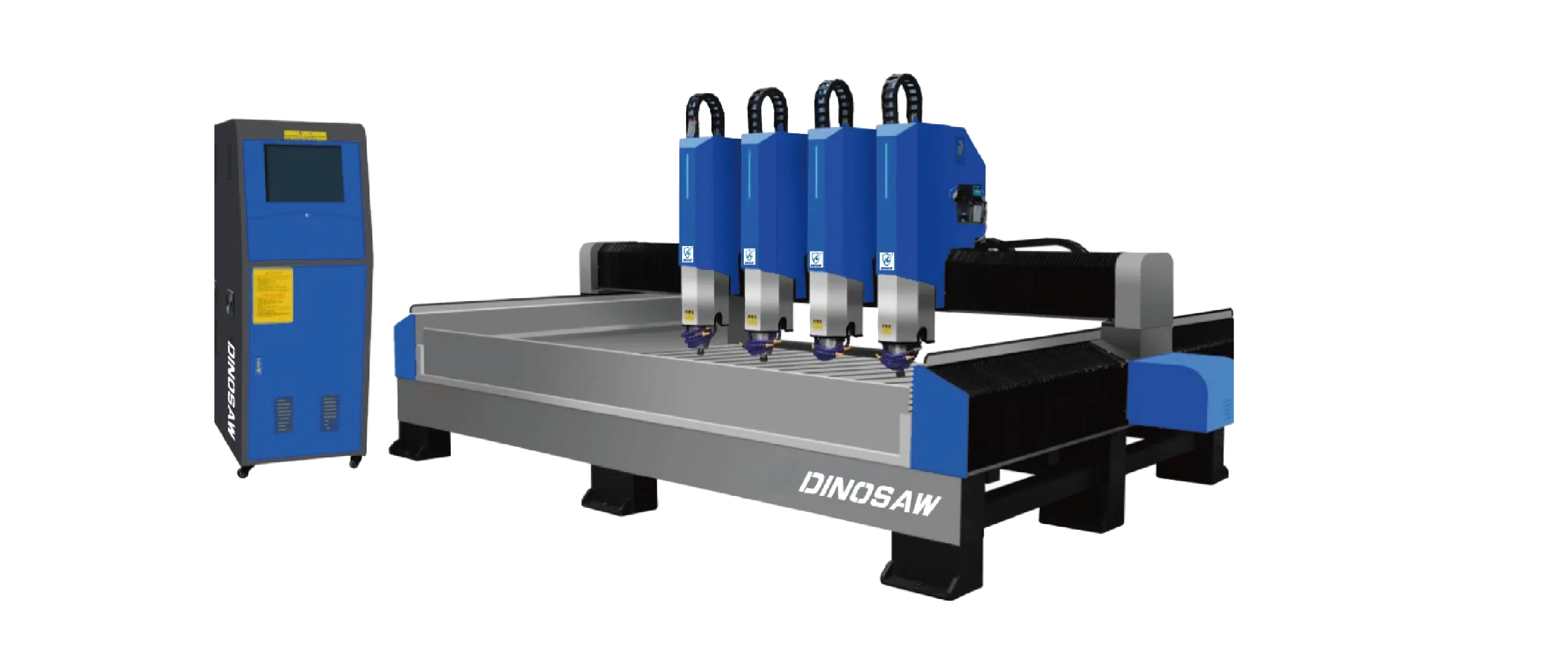

- The "+1" Advantage: When you see "4+1" or "5+1 axis," the "+1" refers to an independent milling spindle. This addition enables tools like end mills and core bits for tasks beyond cutting-sink cutouts, edge profiling, drilling, and engraving. A 4+1 Axis Bridge Saw transforms the machine from a simple saw into a comprehensive work center, dramatically reducing material handling and streamlining production.

Unsure whether a 3, 4, or 5-axis machine fits your projects? Choosing the right configuration impacts your shop's future capabilities. Chat with a Dinosaw expert on WhatsApp for personalized guidance.

The "Brain" and "Eyes": Control & Automation Systems

The mechanical hardware tells only half the story. The control and automation system brings the machine to life, executing complex commands with flawless precision.

The CNC Controller: The Digital Brain

The CNC controller is a hardened industrial computer serving as the machine's brain. It reads programs (G-code) and converts digital commands into precise electrical signals that drive motors for each axis. Renowned systems from Siemens or Fanuc ensure reliability and software compatibility across platforms.

The Software: CAD/CAM Integration

The workflow from design to finished product relies on integrated software:

- CAD (Computer-Aided Design): This is where parts are designed or slab layouts are planned. Operators can import digital templates (DXF files) or use onboard cameras to photograph slabs and nest parts for maximum yield and vein matching.

- CAM (Computer-Aided Manufacturing): The CAM software takes CAD designs and generates toolpaths-the exact route the blade follows. It calculates cutting speeds, feed rates, and entry/exit points before "post-processing" into G-code language the controller understands.

The Operator Interface: Human-Machine Connection

The Human-Machine Interface (HMI) is typically a user-friendly touchscreen on a control pedestal. From here, operators load programs, calibrate the machine, manually control movements, and monitor cutting processes in real-time.

The Support System: Essential Components for Success

Several components are vital for daily operation, safety, and efficiency.

The Worktable: Handling Massive Materials

Given that single granite slabs can exceed one ton, safe loading presents major challenges. Most modern bridge saws feature hydraulic tilting worktables that raise to 85° angles, allowing easy slab loading from forklifts or A-frames. Many tables also rotate 90° or full 360°, enabling cuts on all four workpiece sides without moving heavy materials.

Water Cooling & Dust Suppression: Safety and Performance

Water serves two critical functions: cooling the diamond blade to prevent overheating and premature wear, and suppressing crystalline silica dust. According to OSHA , airborne silica poses serious health hazards in stone fabrication. An effective water delivery system that floods the cut line is non-negotiable for safety and performance.

Beyond Hardware: Maintenance & Safety Excellence

A CNC bridge saw represents a significant investment requiring proper care for longevity and operator protection. While the technology is complex, routine maintenance is straightforward.

Essential Maintenance for Longevity

A simple preventative maintenance schedule prevents costly downtime. For comprehensive guidance, review our detailed bridge saw maintenance guide covering daily, weekly, and monthly checks:

- Daily: Clean sludge and debris from the machine, especially guide rails.

- Weekly: Grease all lubrication points and check water system nozzles.

- Monthly: Inspect diamond blades for segment wear or damage and check drive belt tension.

Critical Safety Features

Modern machines include multiple safety features: blade guards covering spinning blades, emergency stop buttons at key locations, and often "light curtains"-infrared beams that immediately stop the machine if operators enter restricted areas.

Conclusion: Your CNC Bridge Saw Investment Strategy

A CNC bridge saw is a complex, integrated system where every component plays a vital role. Frame stability dictates cut precision. Cutting system power determines production speed. Software intelligence unlocks hardware potential.

The dimension stone industry remains a construction cornerstone, with USGS reporting that over 1.6 million tons were sold or used by domestic producers in 2023. Meeting this demand requires machines that aren't just powerful, but reliable and versatile.

Understanding this anatomy equips you to ask the right questions and make informed decisions. You can evaluate machines not just on price, but on construction quality, axis system capability, and software support. Investing in the right machine, like a Dinosaw 5-Axis CNC Bridge Saw, is an investment in quality, efficiency, and your operation's future profitability.

Ready to explore how a CNC Bridge Saw can revolutionize your workshop? Send us a WhatsApp message , and our technical team will help configure the perfect machine for your needs.

Frequently Asked Questions (FAQs)

What's the real difference between a 3-axis and 5-axis bridge saw?

A 3-axis saw handles basic straight and fixed 45° cuts, perfect for tile and simple countertop jobs. A 5-axis saw adds unlimited tilting and 360° rotation, enabling complex curves, circles, and any miter angle-transforming it into a complete machining center for custom and high-end fabrication.

How much does a professional CNC bridge saw cost?

Pricing varies significantly based on features, size, and brand-typically from $30,000 for basic monoblock models to over $150,000 for fully-featured 5-axis machines with vacuum lifters and advanced software. The investment should be evaluated against ROI in labor savings, material yield, and new shop capabilities.

Is a bridge saw better than a waterjet for stone?

Neither is "better"-they serve different primary purposes. A bridge saw is significantly faster and more cost-effective for straight cuts, which constitute most countertop fabrication work. Waterjets are slower but cut extremely intricate shapes with no heat-affected zones, ideal for custom inlays, specialized parts, and materials that blades might chip. Advanced shops often use both.

What's the typical accuracy of a CNC bridge saw?

High-quality, well-maintained CNC bridge saws should achieve cutting accuracy of ±0.2mm (±0.008 inches) or better. This precision depends on machine rigidity, guide rail and ball screw quality, and properly calibrated control systems. Dinosaw machines are built on heavy, vibration-dampening frames to consistently deliver this precision level.

How much space do I need to install a bridge saw?

Footprint depends on worktable size. A typical monoblock saw for standard slabs might require a 20' x 20' (6m x 6m) area for the machine, operator control area, and safe slab loading/unloading space. Always consult manufacturer technical drawings for specific foundation and clearance requirements.

What power and water supply is needed?

Most industrial CNC bridge saws require 3-phase electrical supply (220V/60Hz or 380V/50Hz) capable of handling at least 60 amps, depending on motor size. For water, a consistent 4-5 gallons per minute (15-20 liters/min) at standard city pressure suffices for blade cooling and dust suppression.

Can a bridge saw cut materials other than stone?

While designed for stone like granite, marble, and quartz, CNC bridge saws fitted with correct diamond blade types can effectively cut other hard materials including sintered stone (like Dekton), porcelain slabs, and concrete. Using blades specifically designed for these materials is crucial to avoid damage and ensure clean cuts.

English

English